Electric vehicle production line packing container unfolding and conveying system

A conveying system and packaging box technology, applied in the field of electric vehicle production line packaging box unfolding equipment innovation, can solve the problems of box body wear, large vibration of the overall equipment, poor use effect, etc., and achieve a reduced occupied area and a high degree of automation. , the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following examples will further illustrate the present invention. The following examples are illustrative and not restrictive, and the scope of protection of the present invention cannot be limited by the following examples.

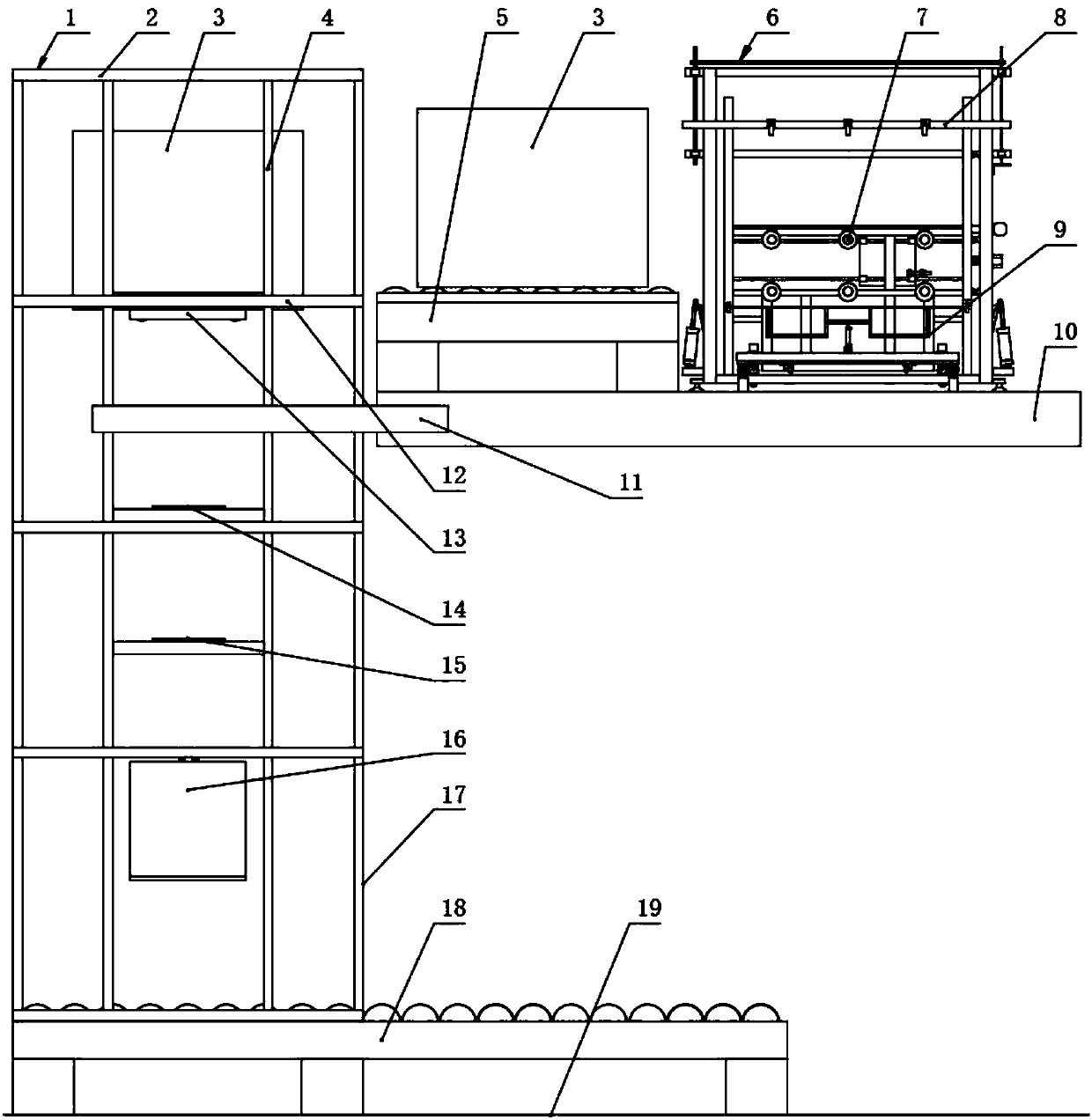

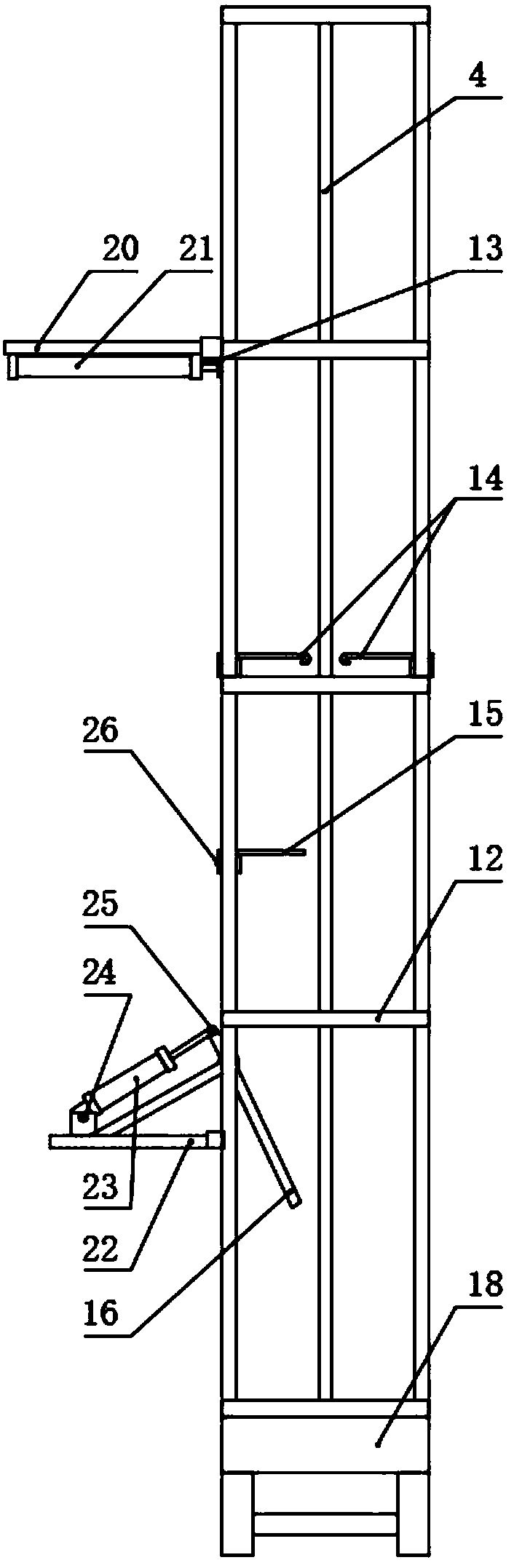

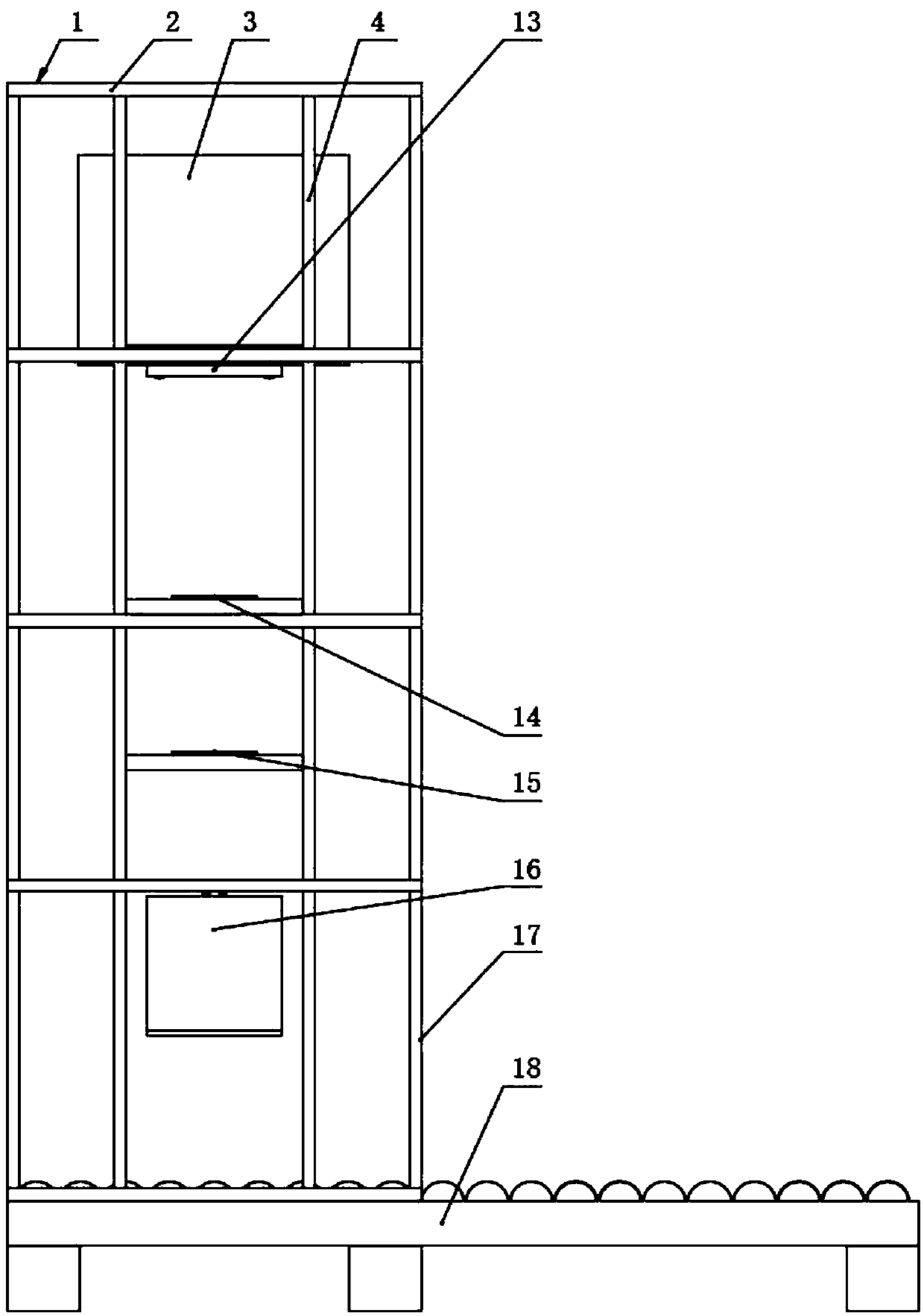

[0044] An unfolding and conveying system for packaging boxes of an electric vehicle production line, such as Figure 1~13 As shown, the innovation of the present invention is that it is composed of a vertical conveying unit 1 and an unfolding conveying unit 6. The unfolding conveying unit is arranged on a scaffold or the second and above floors 10, and the upper end of the vertical conveying unit is located on the scaffold or the second and above Next to the floor, the lower end of the vertical conveying unit is located on the ground 19. The unfolding conveying unit includes a loading module, an unfolding conveying module 7 and a folding fixed module 9. The loading module is used to store the folded packing box 68, and the unfolded conveying modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com