Crane telescopic arm positioning and fixing equipment for water conservancy ship

A technology for fixed equipment and ships, which is applied in the field of positioning and fixed equipment for crane telescopic arms used in water conservancy ships, can solve collision or motion limit, low application rate, and less than effective control and adaptation of height and horizontal distances Sexual changes and other issues, to achieve the effect of improving the degree of fixation, improving the degree of clamping, and improving the application rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

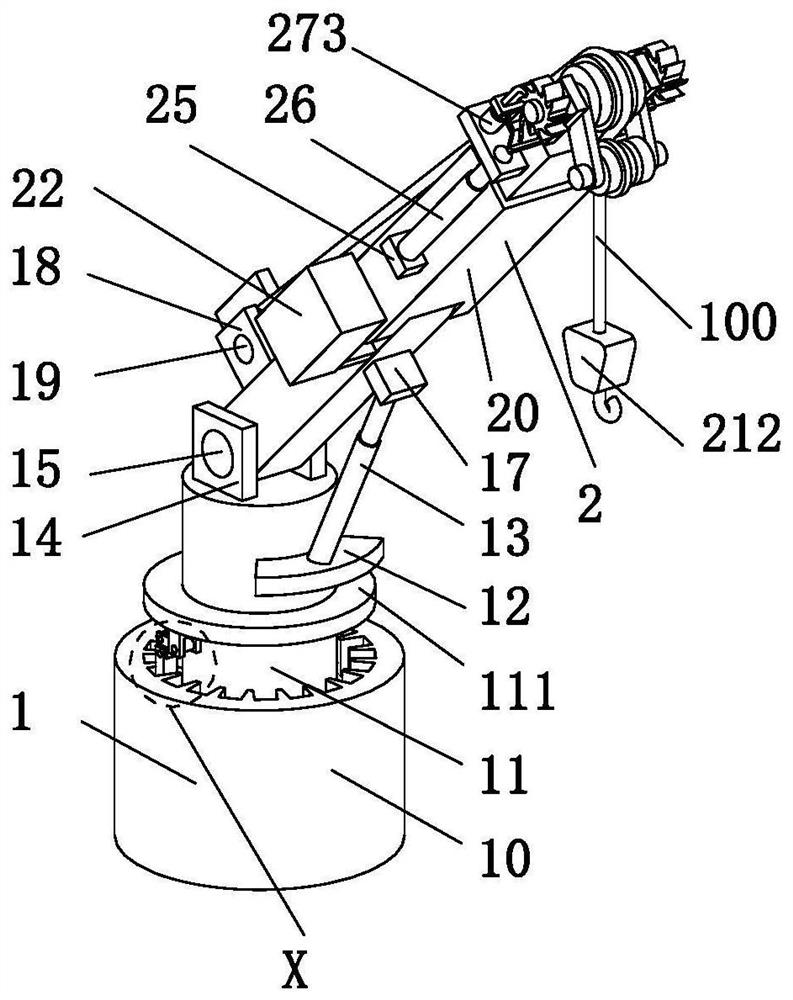

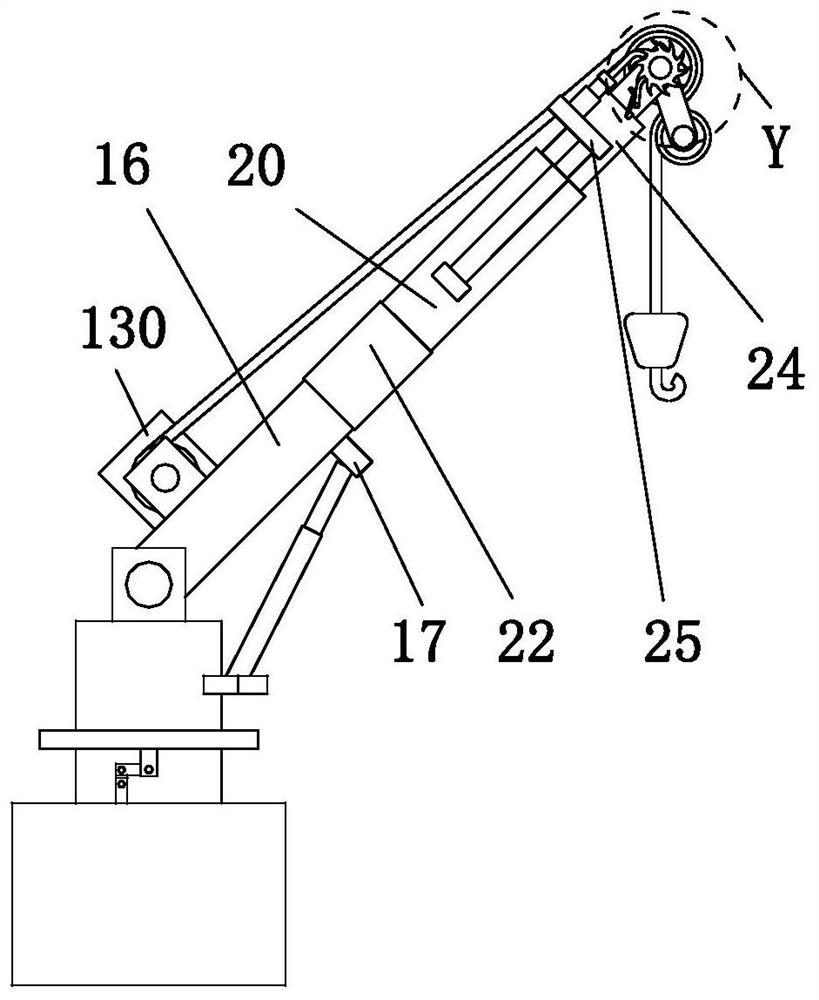

[0031] Such as Figure 1 to Figure 8 As shown, a crane telescopic arm positioning and fixing device for water conservancy ships includes a base mechanism 1 and a main extension mechanism 2. The lower end of the base mechanism 1 is installed on the existing working ground, and the right end of the base mechanism 1 is provided with a main extension mechanism. 2.

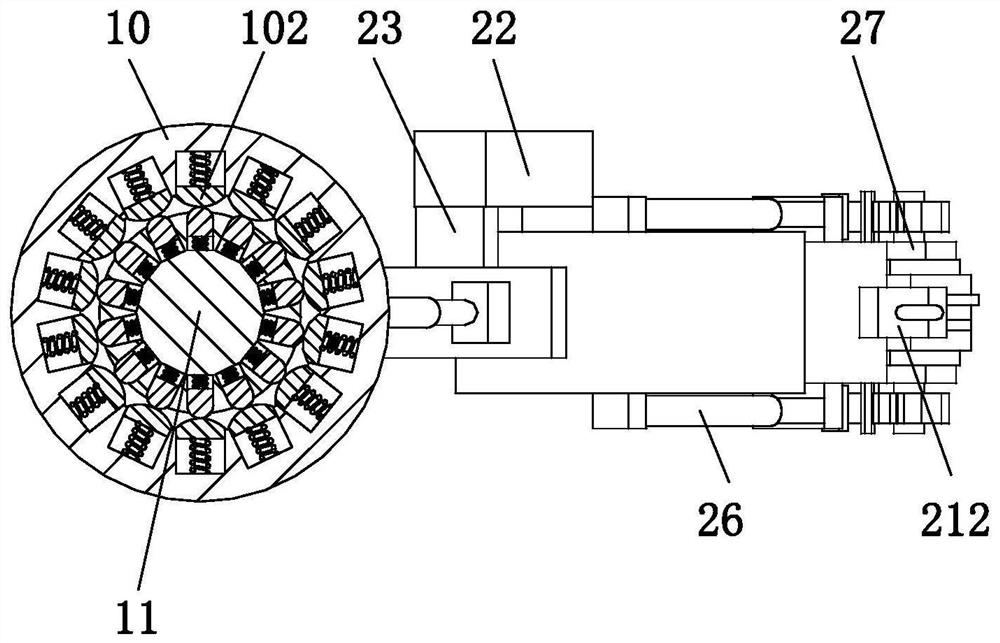

[0032] The base mechanism 1 includes a base 10, a turntable 11, a base 12, a No. 1 electric push rod 13, a No. 1 vertical plate 14, a No. 1 rotating shaft 15, a main rotating rod 16, a bump 17, a No. 2 vertical plate 18, Round bar 19, steel wire rope 100 and No. 1 motor 130, the lower end surface of abutment 10 is installed on the existing working ground, and the upper end middle part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com