Signal centralized control method of truck scale

A control method and signal concentration technology, applied to the detailed information of weighing equipment, measuring devices, instruments, etc., can solve the problems of different signal control methods of truck scales, increased implementation and maintenance costs, and high degree of business process coupling. Achieve the effect of improving the scope of control and reuse rate, improving security and stability, and low coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

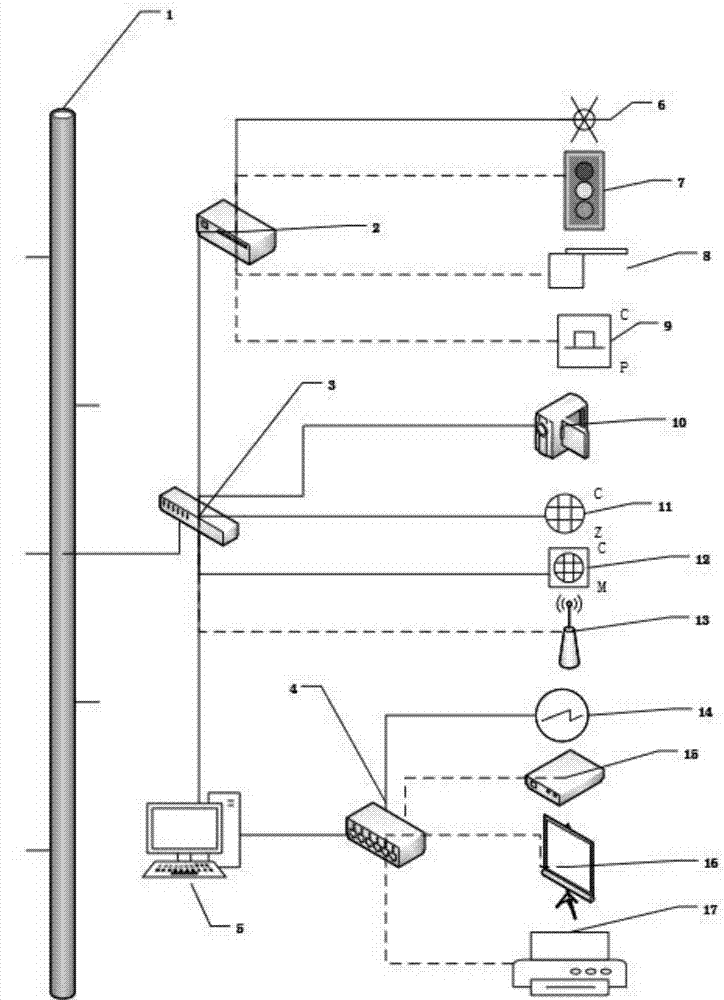

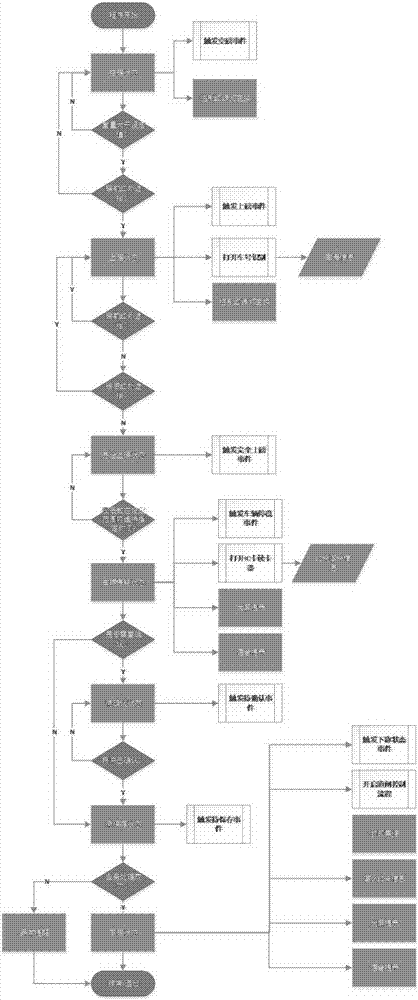

[0026] The specific implementation mode of the present invention is as follows:

[0027] (1) When the weighing instrument data is less than the set value, it is judged as an empty scale state, and at the same time, the traffic light signal is controlled to give a traffic reminder; when the state changes from other states to this state, the corresponding event is triggered and the manual trigger function is reserved;

[0028] (2) When the data of the weighing instrument is greater than the set value and the infrared (grating) in front of the weighing is blocked, it will enter the weighing state, and at the same time start the vehicle number recognition, and change the traffic light prompt; when the state changes from other states to this state, trigger Corresponding events and reserved manual trigger function;

[0029] (3) When the data of the weighing instrument is greater than the set value, and the infrared (grating) before and after the weighing is not blocked, it will ente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com