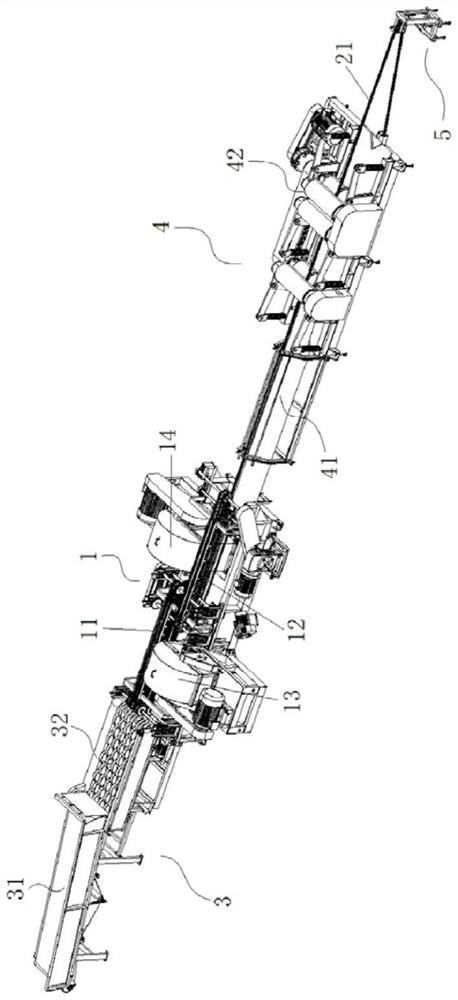

Hemp scraping device and plant fiber extraction equipment

A technology for extracting equipment and plant fibers, used in fiber processing, fiber mechanical separation, textile and papermaking, etc. performance, reduce labor costs, and facilitate operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

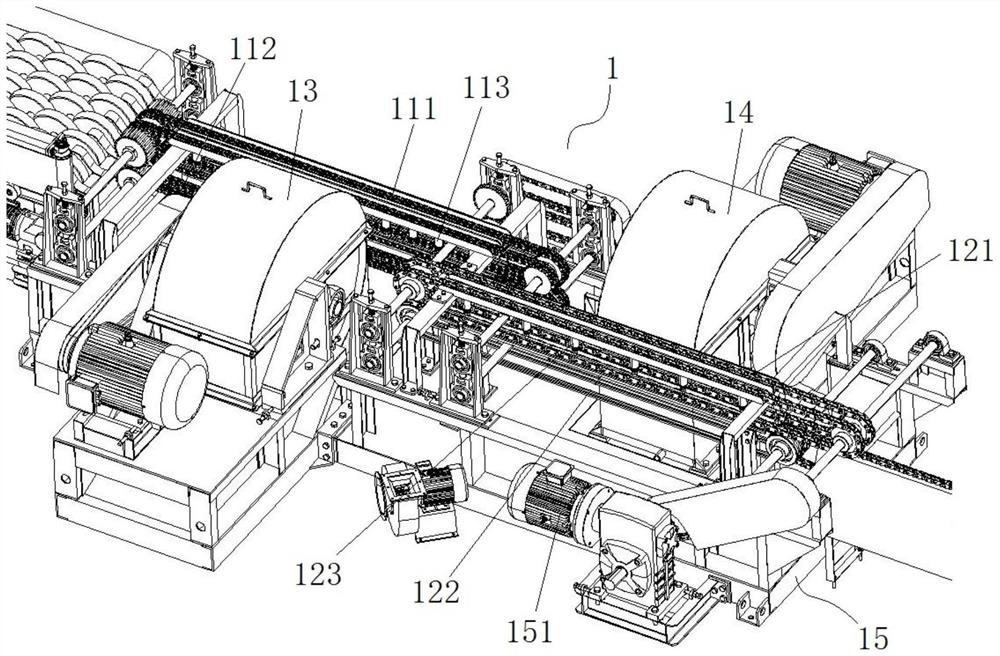

Embodiment 1

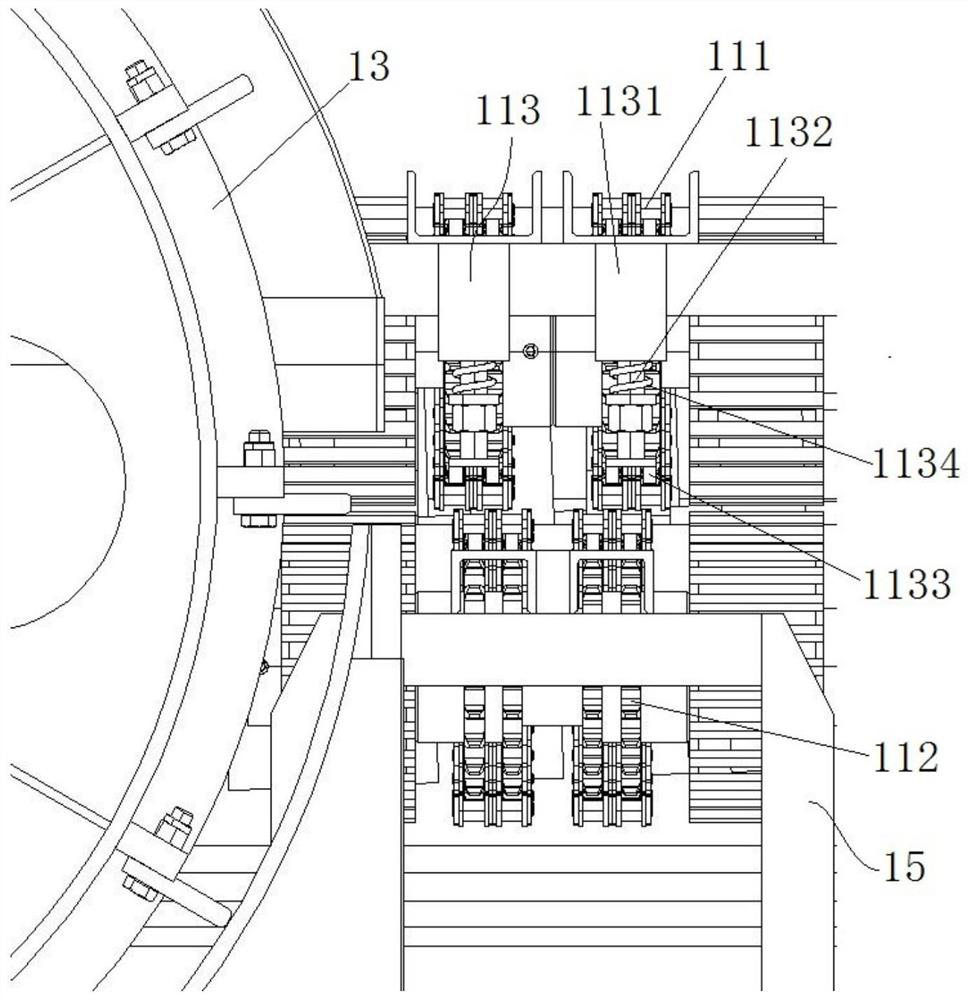

[0053] like Figure 1-8 As shown, a kind of hemp scraping device 1 is provided in the present embodiment, which mainly includes a first hemp chain group 11 and a second hemp chain group 12, and corresponding to the first hemp chain group 11 and the second hemp chain The first scraper ball 13 and the second scraper ball 14 are respectively provided in the group 12 .

[0054] In this embodiment, the raw material output end of the first embossed chain group 11 is connected to the raw material input end of the second embossed chain group 12; The embossed hemp chain groups 12 are all arranged along the length direction of a straight line, and the projections of the raw material output end of the first embossed hemp chain group 11 and the raw material input end of the second embossed hemp chain group 12 on the straight line exist overlapping. As one of the specific arrangement forms, the first embossed chain set 11 and the second embossed chain set 12 in this embodiment are arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com