Self-locking variable direction core-pulling device for injection mold

A technology for injection molds and core-pulling devices, which is applied in the field of self-locking and reversing core-pulling devices for injection molds, and can solve problems such as product scrapping, complex mold structures, and low efficiency of core-pulling and demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

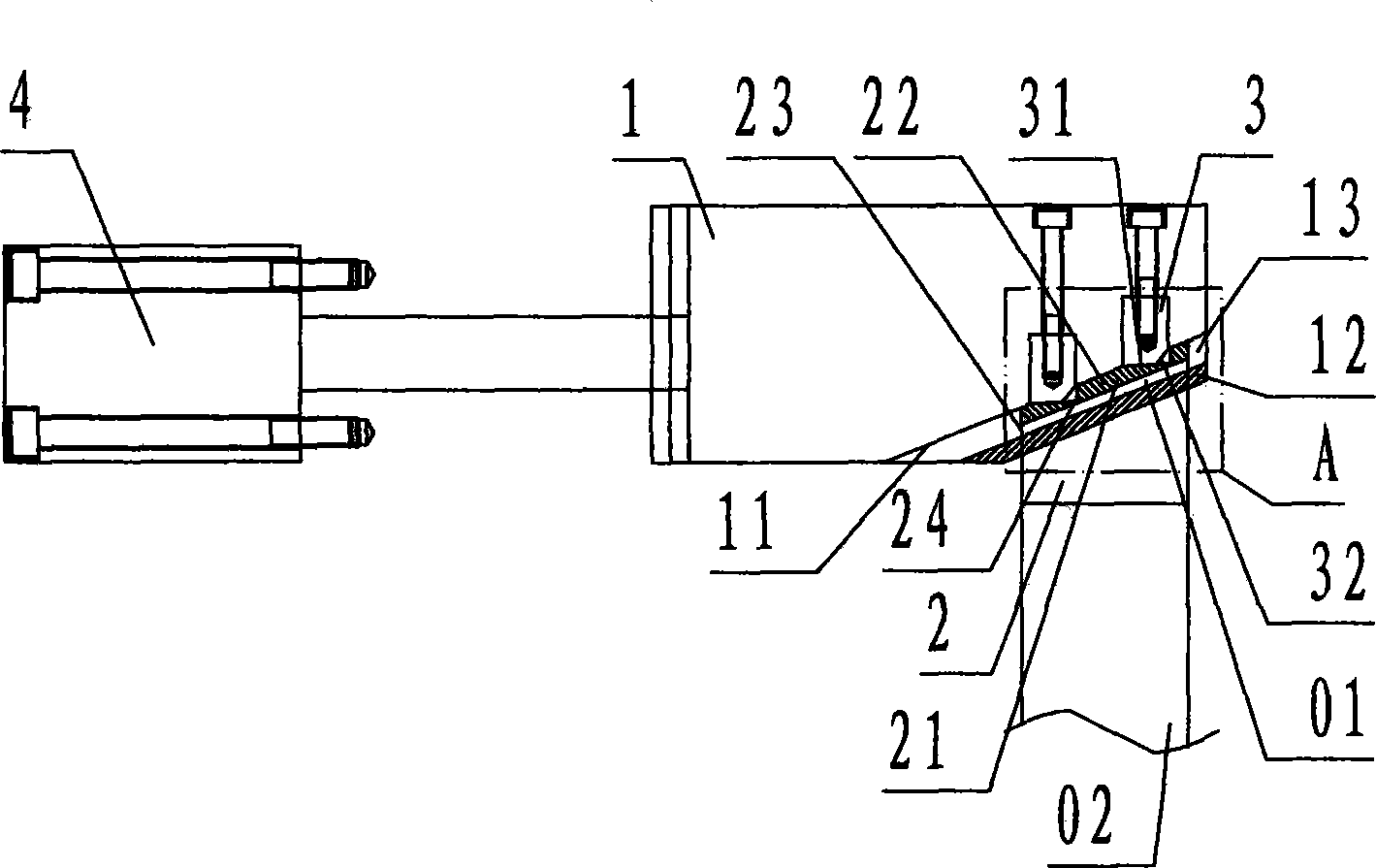

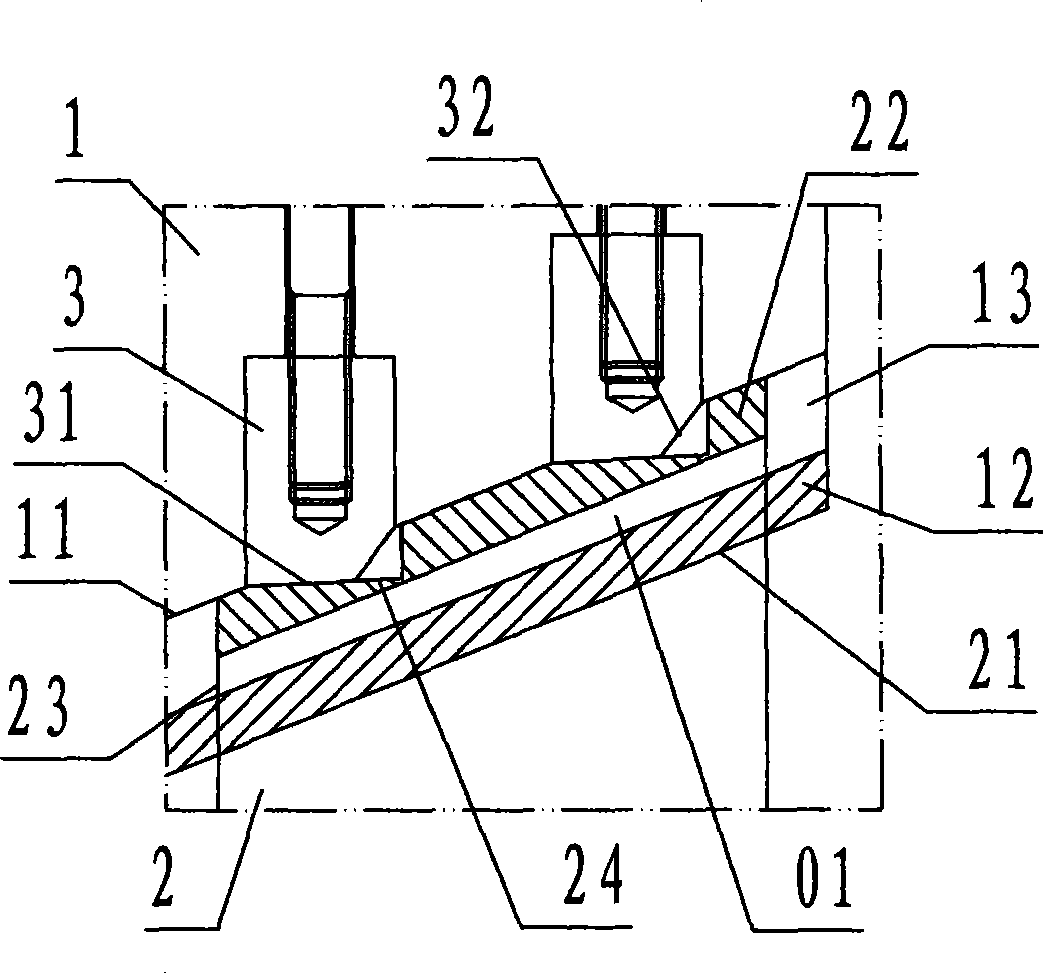

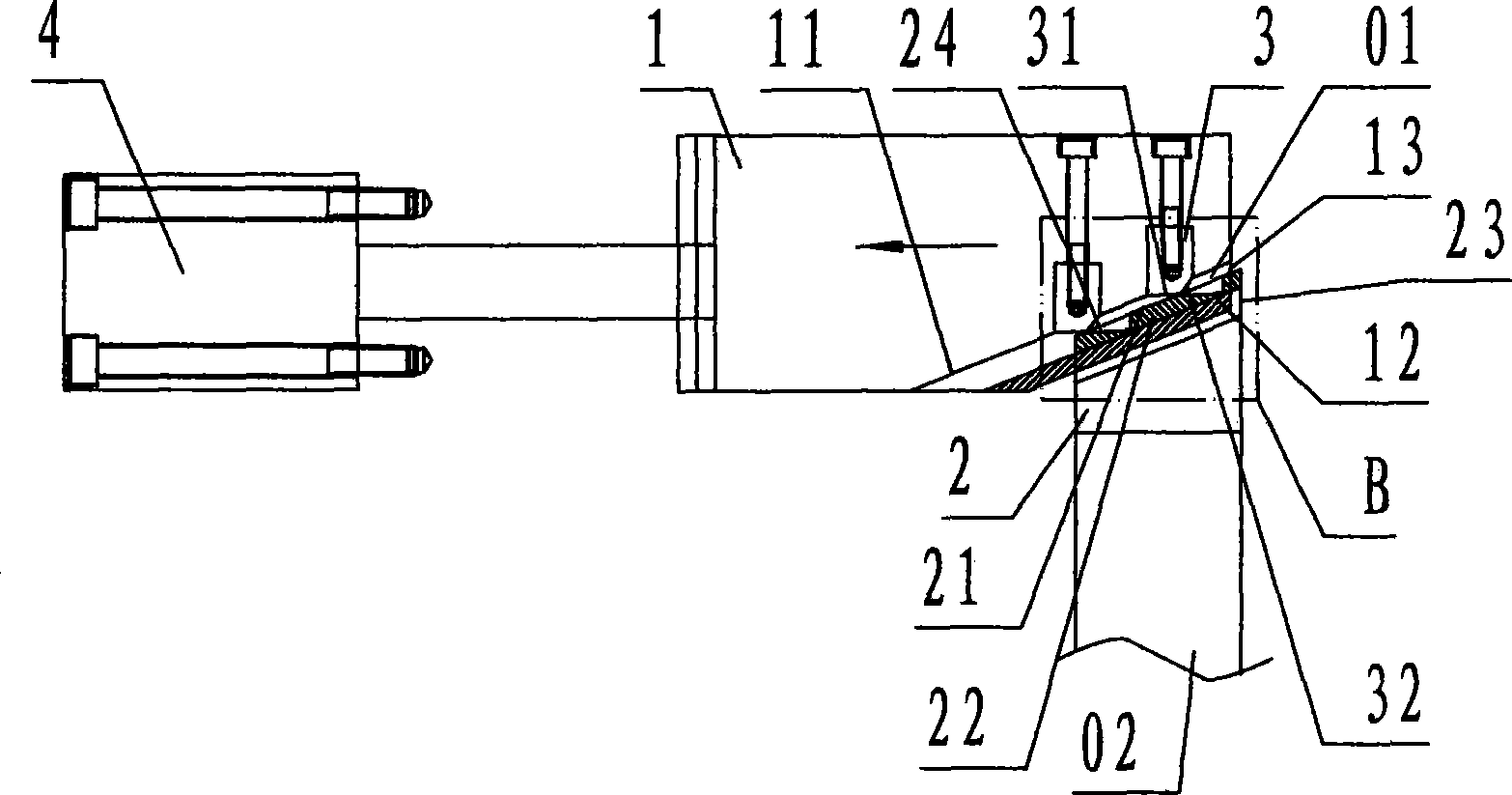

[0022] refer to Figure 1 to Figure 5 , a core-pulling device for self-locking and direction-changing injection molds of the present invention, including a driving wedge slider 1, a driven wedge slider 2, a self-locking block 3, and an oil cylinder 4, wherein: the driving wedge slider 1 is as follows There is a wedge-shaped block steel member with a slope of 22° to 30° from left to right between it and the right side. The slope of the active wedge slider 1 is provided with a T-shaped channel in cross section, which is called a T-shaped chute. 11. The notch edge of the T-shaped chute 11 is called the eaves 12, and the distance between the top of the eaves 12 and the bottom of the trough is called the groove space 13;

[0023] The driven wedge slider 2 is a wedge-shaped block-shaped steel member provided with the same inclined surface as the active wedge slider 1, and the inclined surface of the driven wedge slider 2 is provided with a T-shaped track in cross section called T-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com