Hydraulic tensioner

A hydraulic tensioner, tension technology, applied in transmission, belt/chain/gear, mechanical equipment, etc., can solve problems such as vibration, large gap between claw-shaped elements and lateral holes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

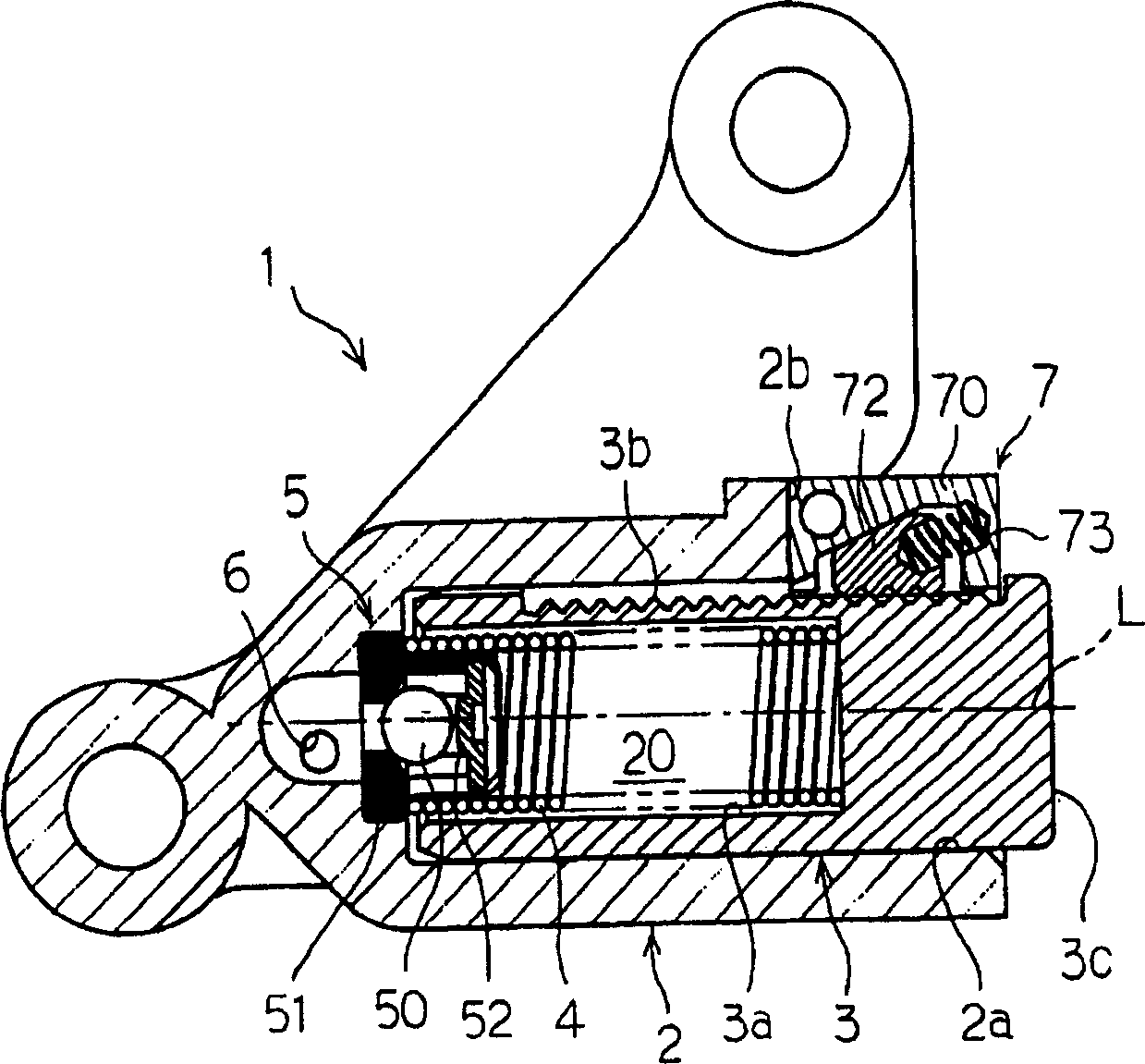

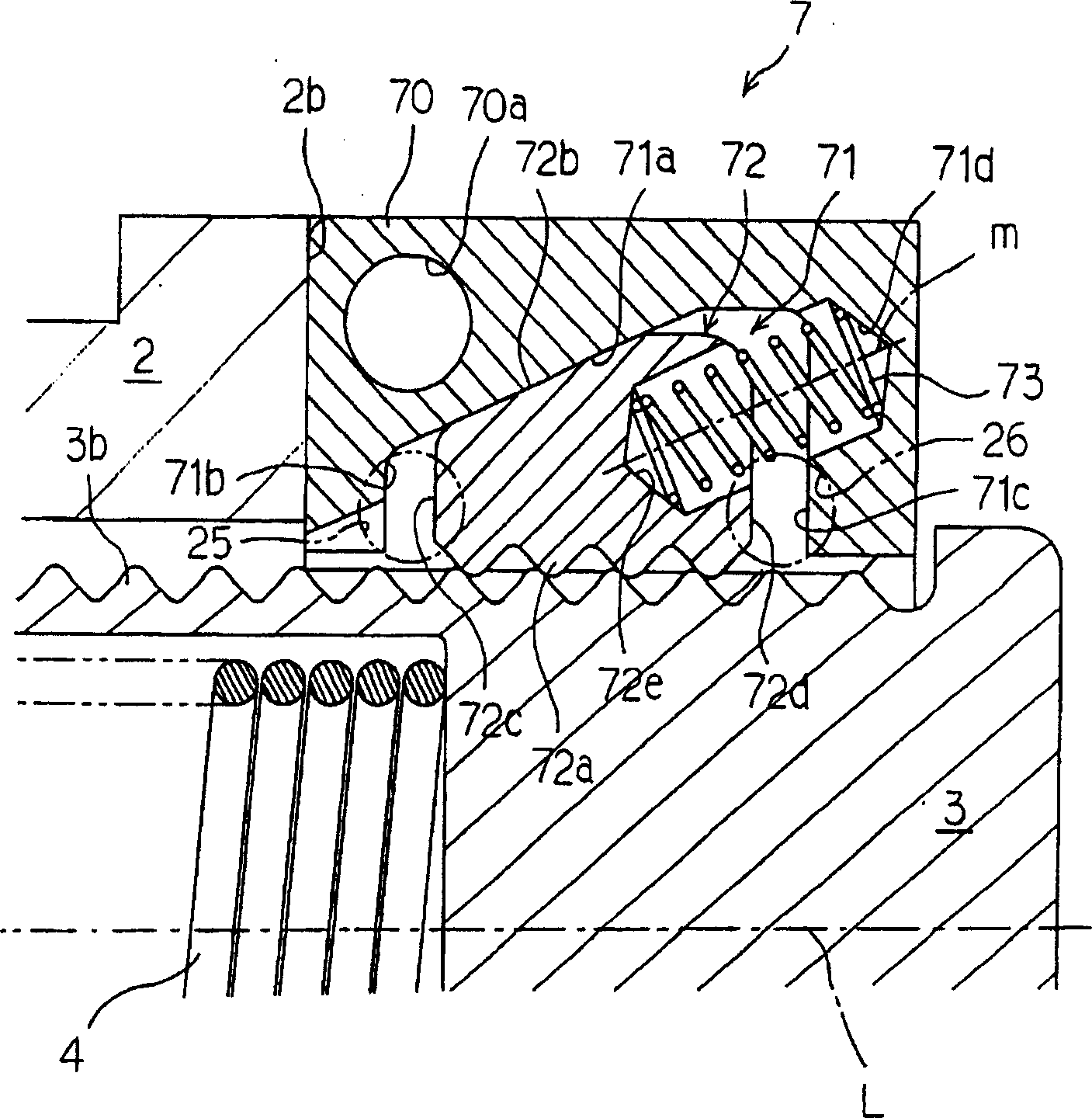

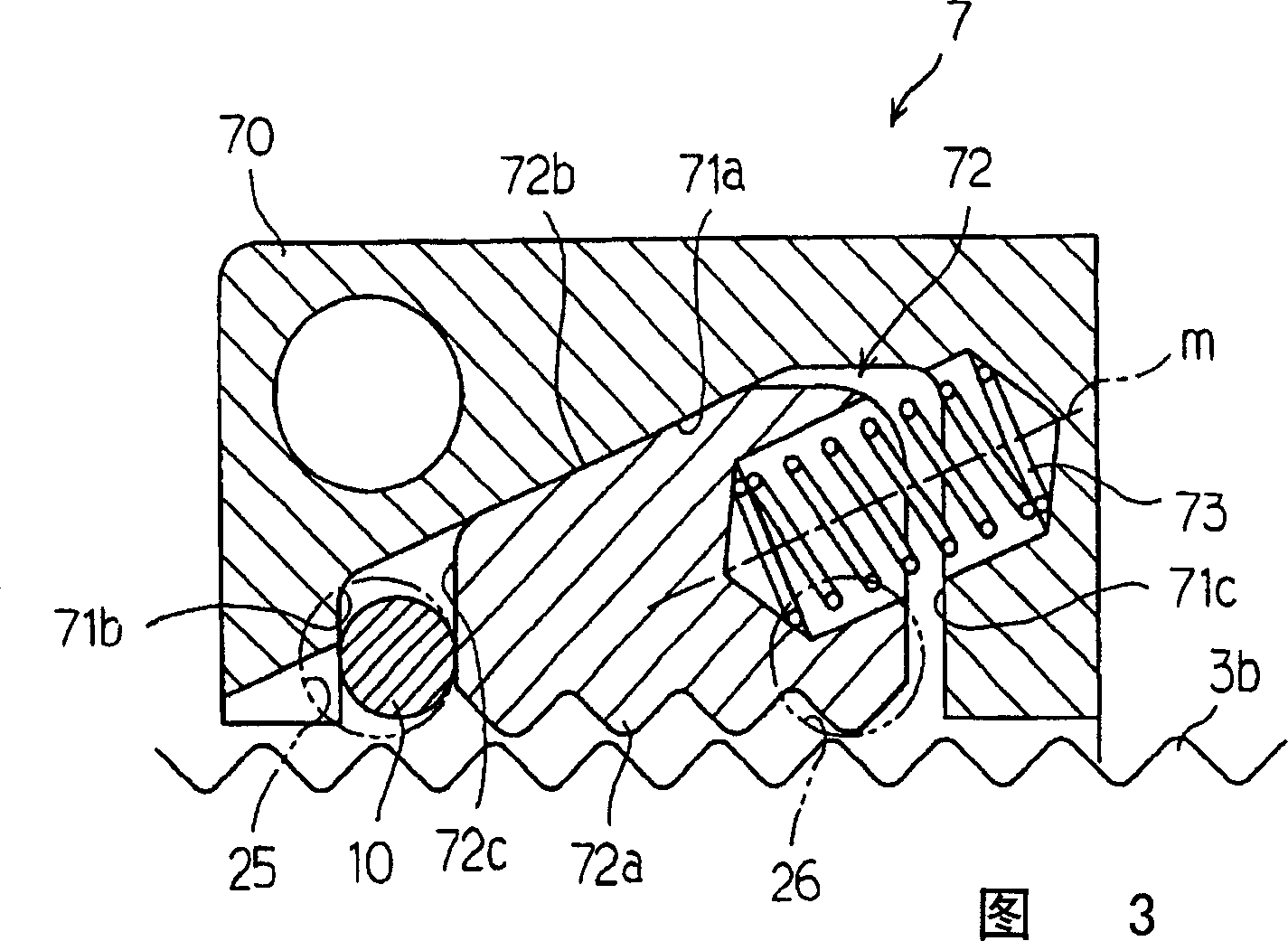

[0020] Such as figure 1 As shown, the hydraulic tensioner 1 includes a housing 2, a hollow plunger 3 slidably installed in a hole 2a of the housing 2, and a spring 4 as a first pressing element, which moves along the hollow plunger 3 The plunger is pushed in the direction protruding from the hole 2a.

[0021] In the housing 2 , a fluid chamber 20 is formed by an internal space 3 a between the inner wall surface of the hole 2 a and the interior of the plunger 3 . A one-way valve 5 is provided at the bottom of the inner hole 2a of the housing to allow the fluid to flow into the cavity 20, but prevent the fluid from flowing in the opposite direction. The one-way valve 5 includes a ball 50 , a ball seat 51 in contact with the ball 50 , and a pressing spring 52 pushing the ball 50 toward the ball seat 51 . The formation of the one-way valve can also adopt any other suitable structure. The housing 2 also has a fluid channel 6 for communicating the cavity 20 with an external sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com