Numerical control servo automatic bending machine

A bending machine and servo motor technology, applied in the field of CNC servo automatic bending machine, can solve the problems of low production efficiency, only one-way bending, large floor space, etc., to achieve greatly increased efficiency, stable and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

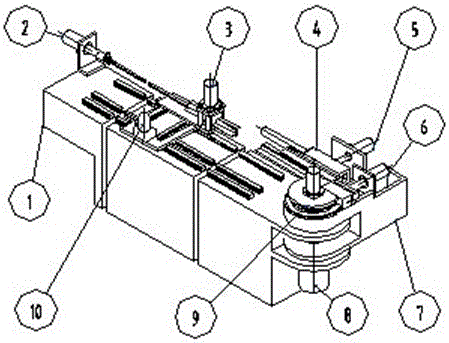

[0010] A CNC servo automatic bending machine, comprising a body 1, a core pulling device 2, a feeding and clamping device 3, an auxiliary pushing mechanism 4, an auxiliary pushing oil cylinder 5, a clamping oil cylinder 6, a driving arm 7, a rotary servo motor 8, a bending machine Die 9, feeding device 10, bending die 9 is divided into two parts, the upper die can move up and down, loose clamp the workpiece, the rotary servo motor 8 drives the mold, and the servo motor drives the feeding to ensure the length, width and angle accuracy of the frame; core pulling device action to ensure the accuracy of the bending arc.

[0011] Before working, input the relevant parameters of the frame to be processed into the program in advance. Put the profile into the mold and stick it close to the mold, push the clamping cylinder 6 forward to clamp the workpiece (profile); the core pulling device 2, its tail (left) end is connected with the core pulling cylinder, and the cylinder extends to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com