S-shaped feeding device for inlay winding and conveying

A technology of feeding device and driving roller, which is applied in the field of RFID tag generation, can solve the problems of inconsistent clamping force of the substrate, affecting the positioning accuracy of the substrate, and high purchase cost of the cylinder, so as to achieve stable substrate feeding, simple structure, and small space occupation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited to the following embodiments.

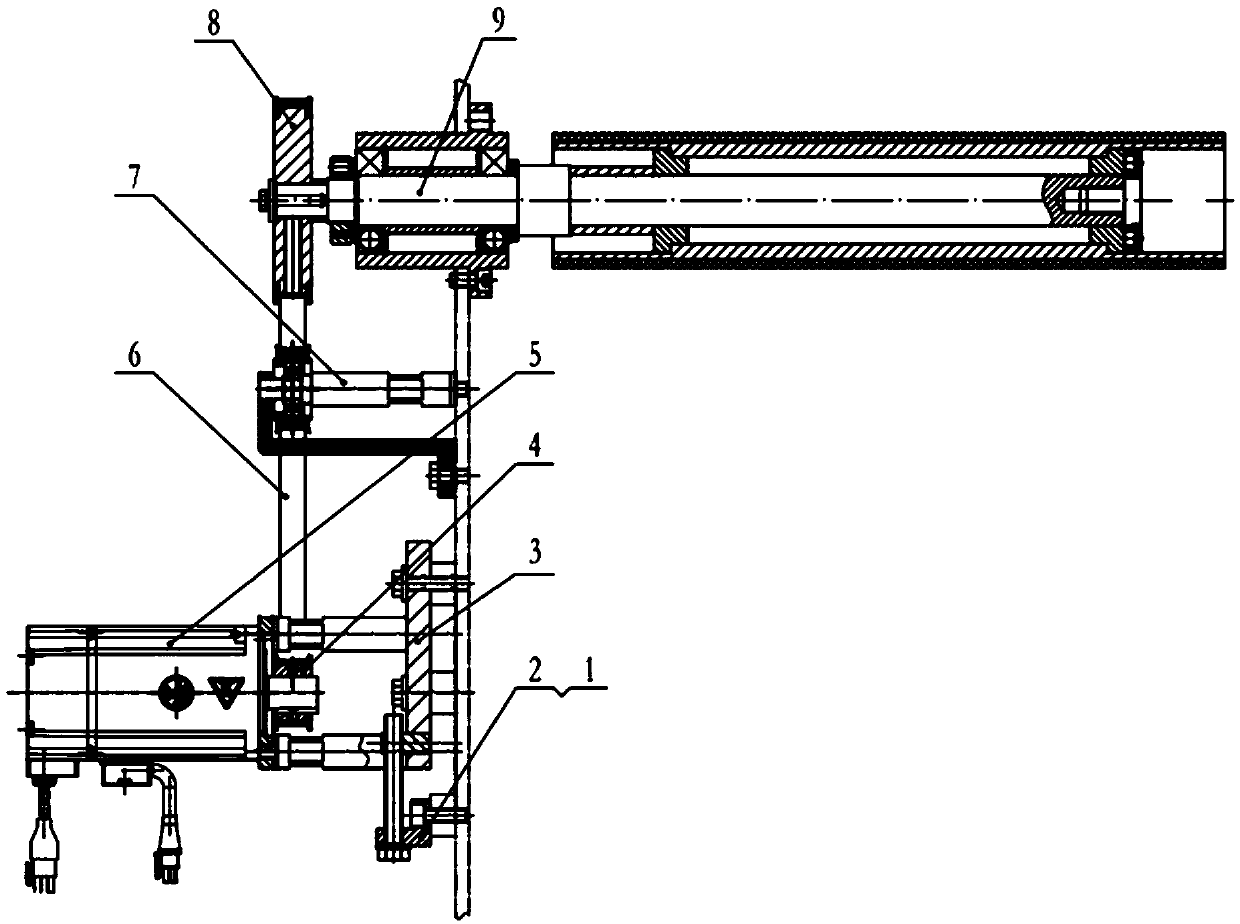

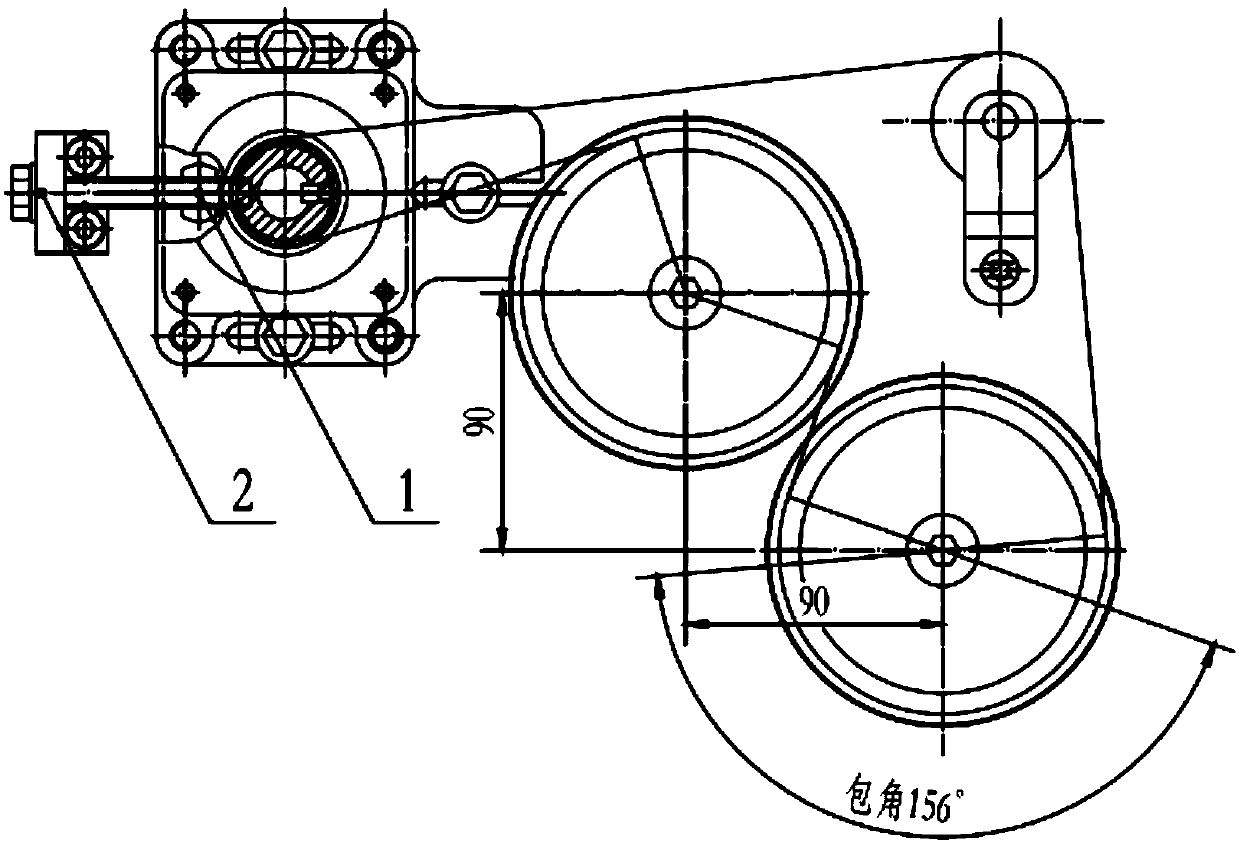

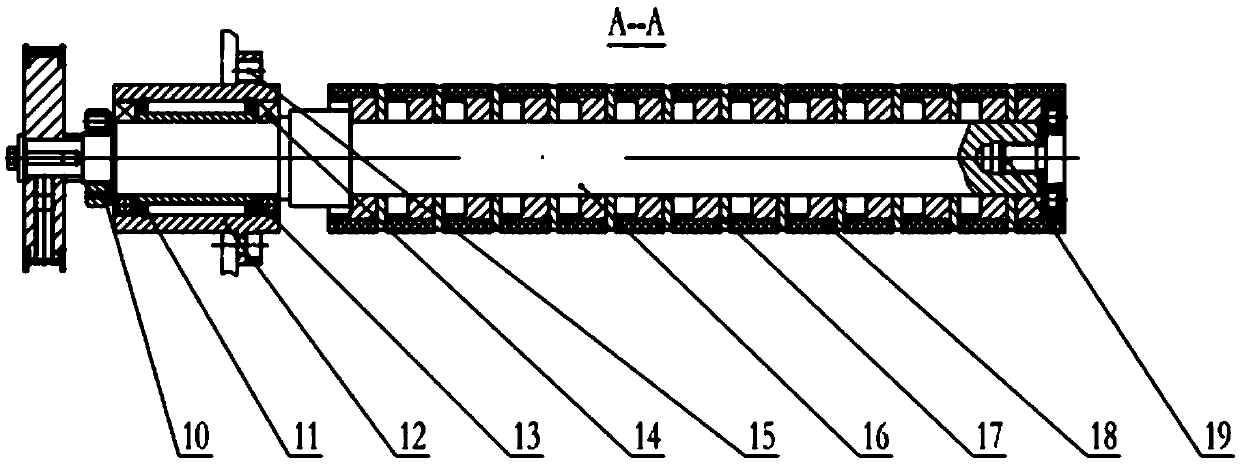

[0019] The structure of the "S" shaped feeding device used for inlay winding transportation provided by the present invention is as follows: figure 1 and figure 2 Shown, comprise motor 5, drive small wheel 4, motor seat 3, double-sided synchronous belt 6, swivel caster assembly 7, driving pulley 8, driving roller 9 and lower driving roller ( figure 1 Middle and lower driving rollers are not shown), wherein the motor is installed on the motor base, the driving small wheel is installed on the output shaft of the motor, and the double-sided synchronous belt is sleeved on the driving small wheel, and the driving pulley is provided with two, respectively Used to drive the rotation of the driving roller and the lower driving roller, the double-sided syn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com