Numerical control double-end pin hole drilling machine

A pinhole and double-head drill technology, which is applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of low precision and efficiency, difficulty in meeting high-precision product requirements, etc., achieve automation and increase production efficiency, Guaranteed processing accuracy and the effect of ensuring feed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

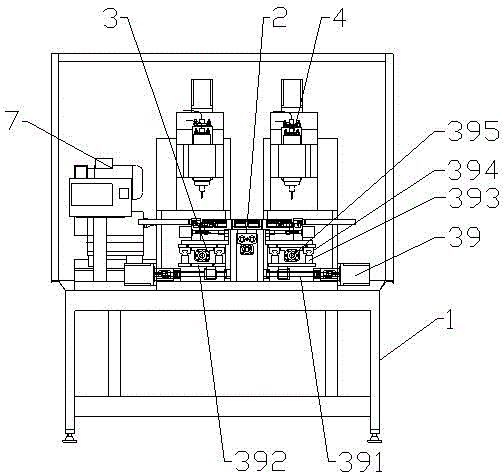

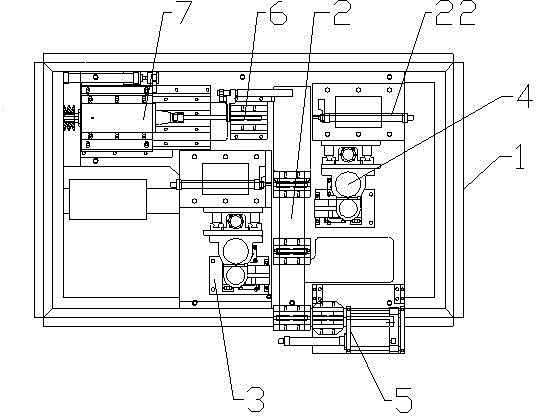

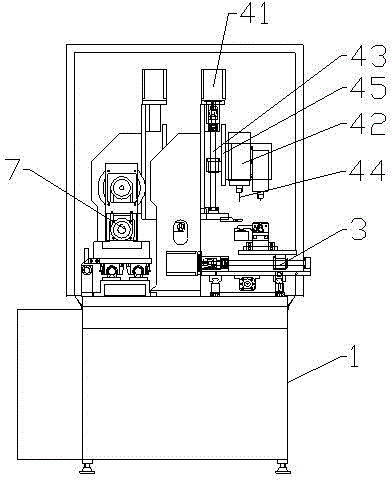

[0032] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 18 As shown, this kind of CNC double-headed pinhole drilling machine is controlled by a PLC control system and also includes a frame 1 on which an intermediate feeding mechanism 2 in the front and rear directions is installed, and on both sides of the intermediate feeding mechanism 2 Each is provided with a fixture assembly 3 with the same structure and opposite directions. The fixture assemblies 3 can slide back and forth, left and right on the frame 1, and one is in front of the other. The drilling mechanism 4; the front end of the frame 1 is provided with an automatic feeding mechanism assembly 5; the rear end of the clamp assembly 3 located at the front end is also provided with a reaming fixture assembly 6, next to the reaming fixture assembly 6 A hinged light mechanism assembly 7 is provided, wherein, such as Figure 4 , 5 , shown in 6, the assembly of automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com