Guide wheel dresser feeding structure of air valve rod-part numerical control centerless grinding machine

A centerless grinding machine and dresser technology, which is applied in the direction of grinding machine parts, grinding machines, and machine tools designed for grinding the rotating surface of workpieces, etc. Problems such as low precision of guide wheel dresser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

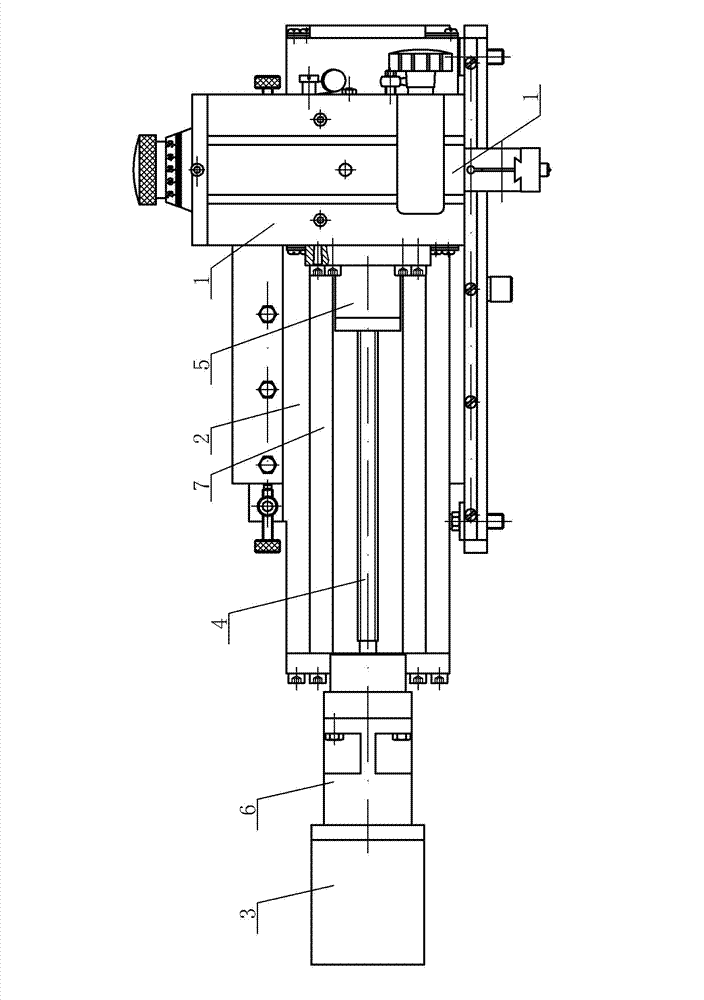

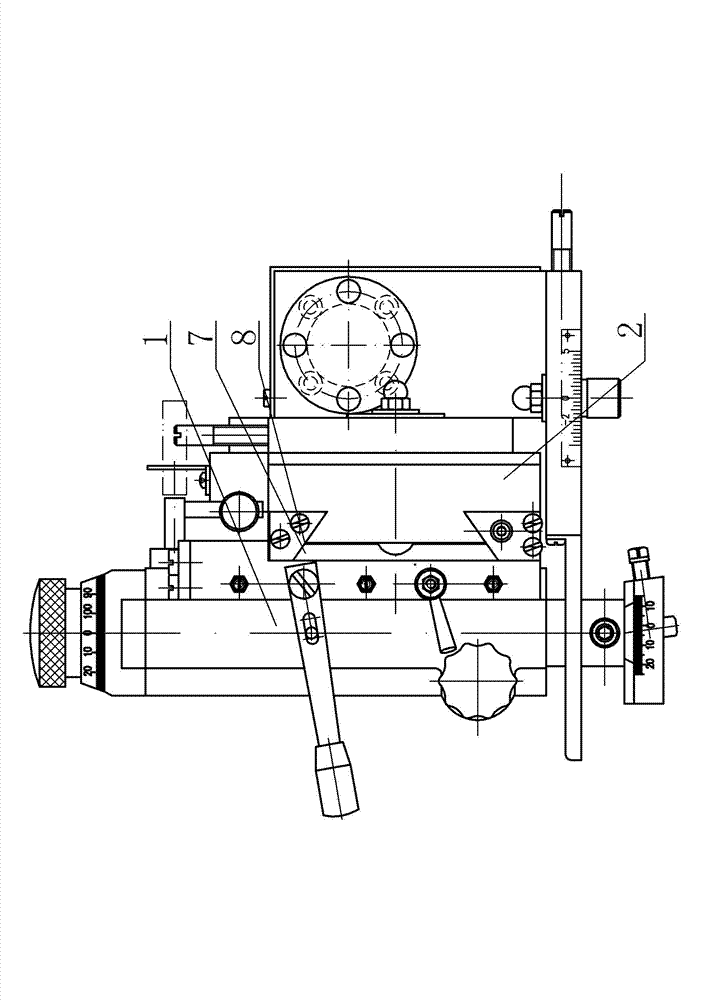

[0008] See figure 1 , figure 2 , which includes a guide wheel dresser 1, a base 2, a servo motor 3, a ball screw 4, a screw nut 5, the guide wheel dresser 1 is supported on the base 2, the servo motor 3 is connected to the input end of the reducer 6, and the reducer 6 The output end of the ball screw 4 is connected to the input end of the ball screw 4, the ball screw 4 is threadedly connected with a screw nut 5, one end of the screw nut 5 is fastened to the guide wheel dresser 1, and the upper end face of the base 2 is provided with a dovetail linear guide groove. 7. The bottom of the guide wheel dresser 1 is provided with a dovetail guide rail 8 , and the dovetail guide rail 8 is embedded in the dovetail linear guide rail groove 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com