Fully-automatic metal band sawing machine

A metal belt, fully automatic technology, applied in the direction of metal sawing equipment, sawing machine, metal processing, etc., can solve the problems that the servo drive system cannot output continuous control amount, precise positioning is impossible, and the servo motor loses its meaning, etc., to achieve structural Simple, convenient installation and transportation, high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

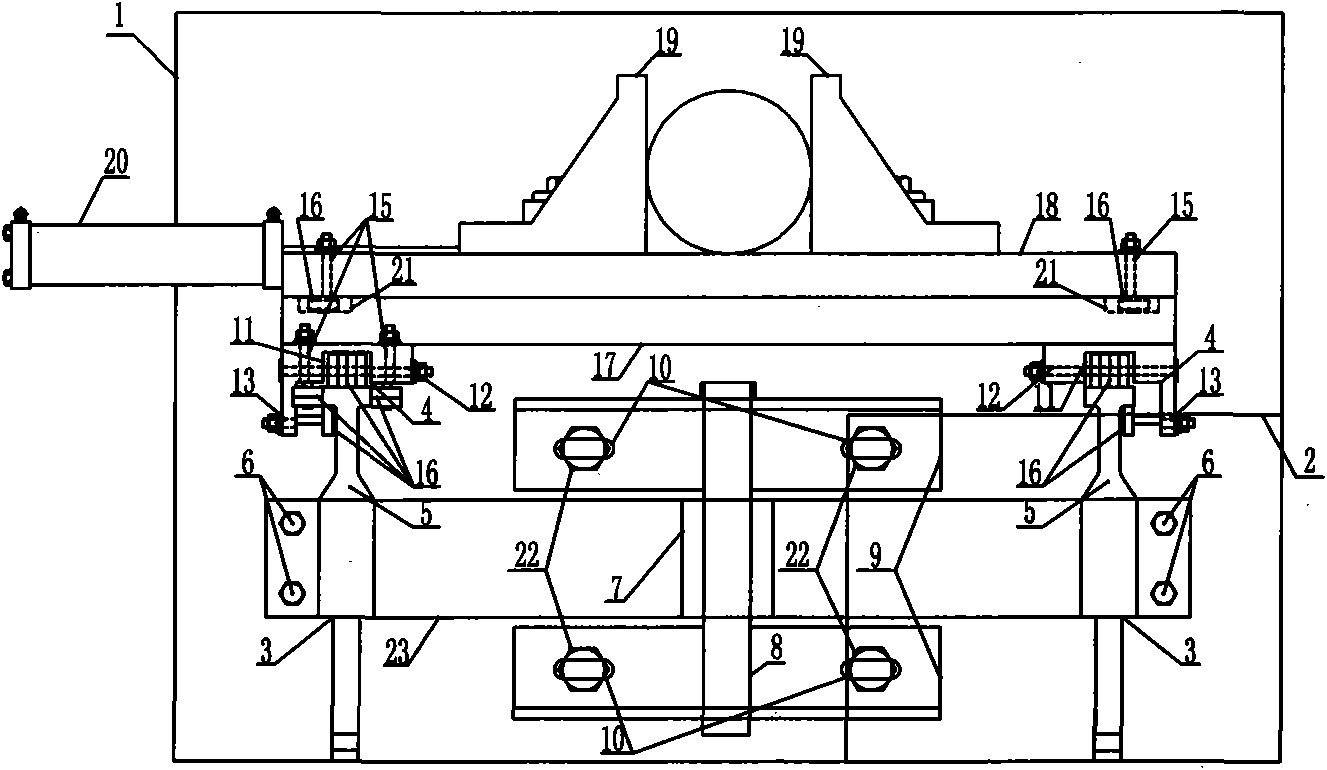

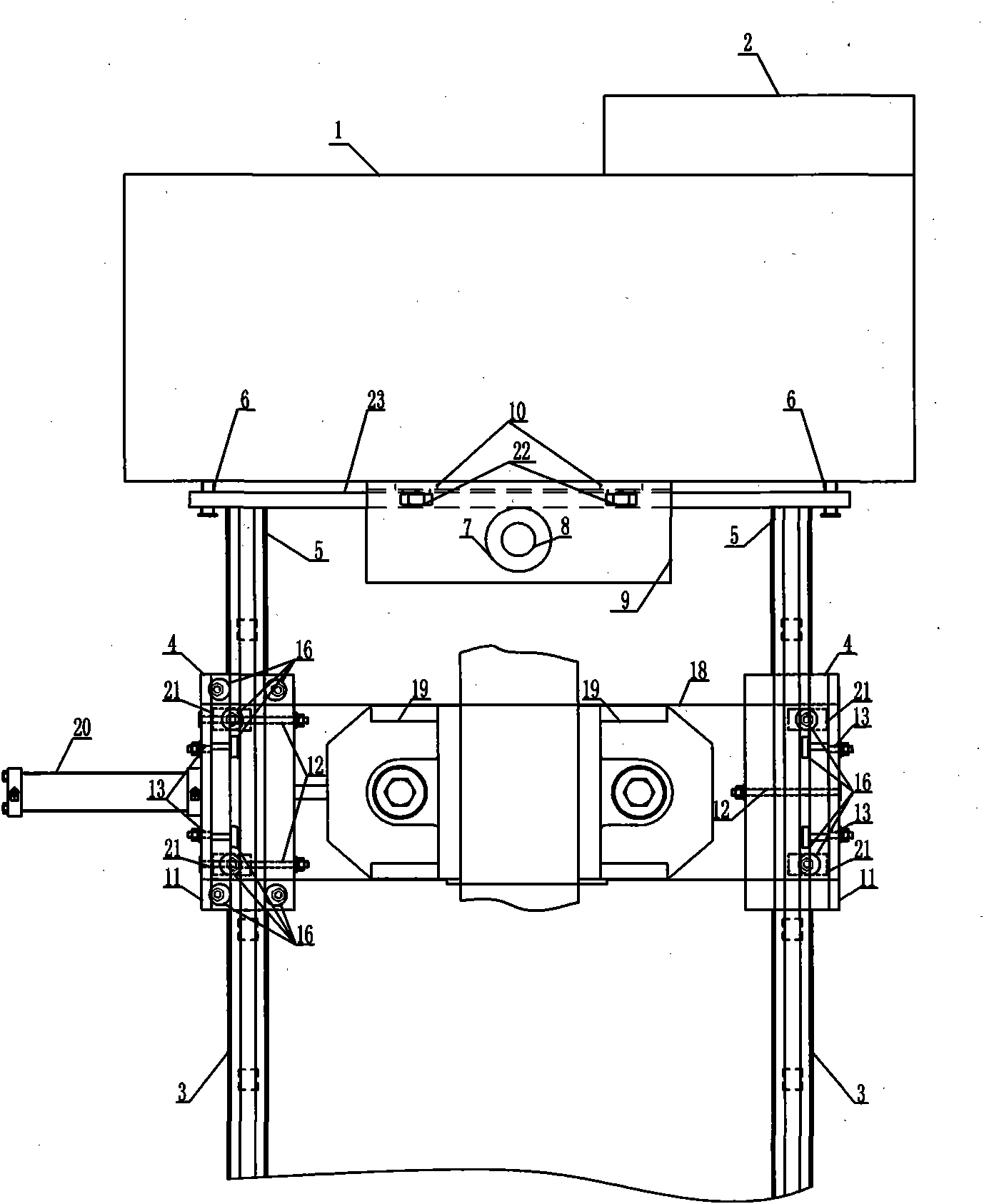

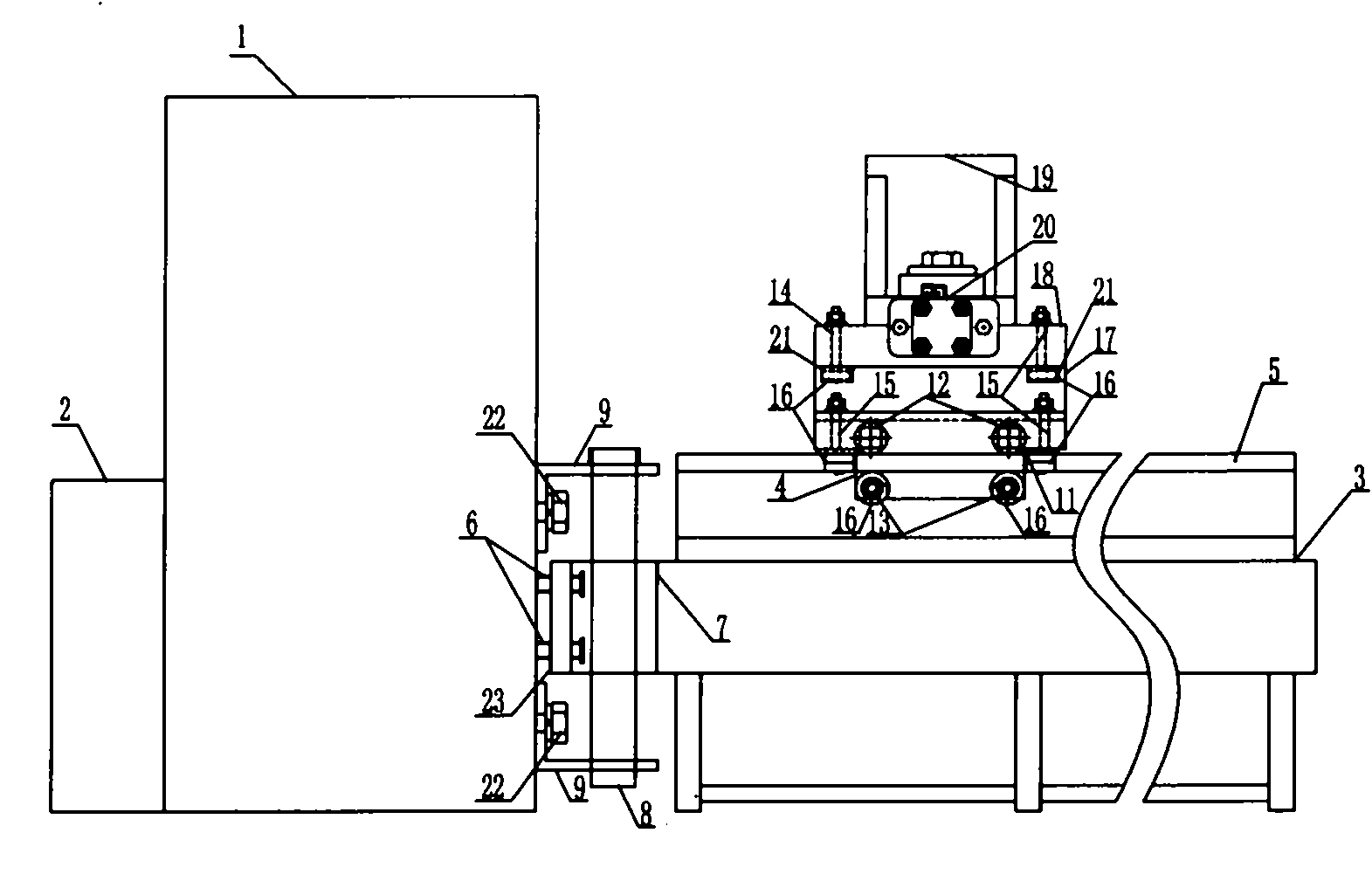

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] A fully automatic metal band sawing machine of the present invention, its structure comprises a band sawing machine 1, a numerical control device 2, a feeding table 3 and a feeding trolley 4, the band sawing machine 1 is provided with a numerical control device 2, and the feeding table 3 is installed on the band sawing machine 1 On one side, the feeding trolley 4 is set on the feeding table 3; the numerical control device 2 is provided with a single-chip microcomputer control module for controlling the technological process of the fully automatic metal band sawing machine.

[0024] The feeding platform 3 is provided with a feeding vehicle guide rail 5, a front panel 23, an adjusting bolt 6, a vertical sliding sleeve 7, a mandrel 8 and concentric hanging ears 9, and two symmetrical feeding vehicle guide rails 5 are arranged above the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com