Automatic pipe cutting machine

A pipe cutting machine, automatic technology, applied in the direction of metal processing, etc., can solve the problems of unfavorable automatic processing of pipe cutting machines, increase enterprise costs, high equipment prices, etc., to achieve the effect of reducing input costs, improving stability, and preventing material jams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

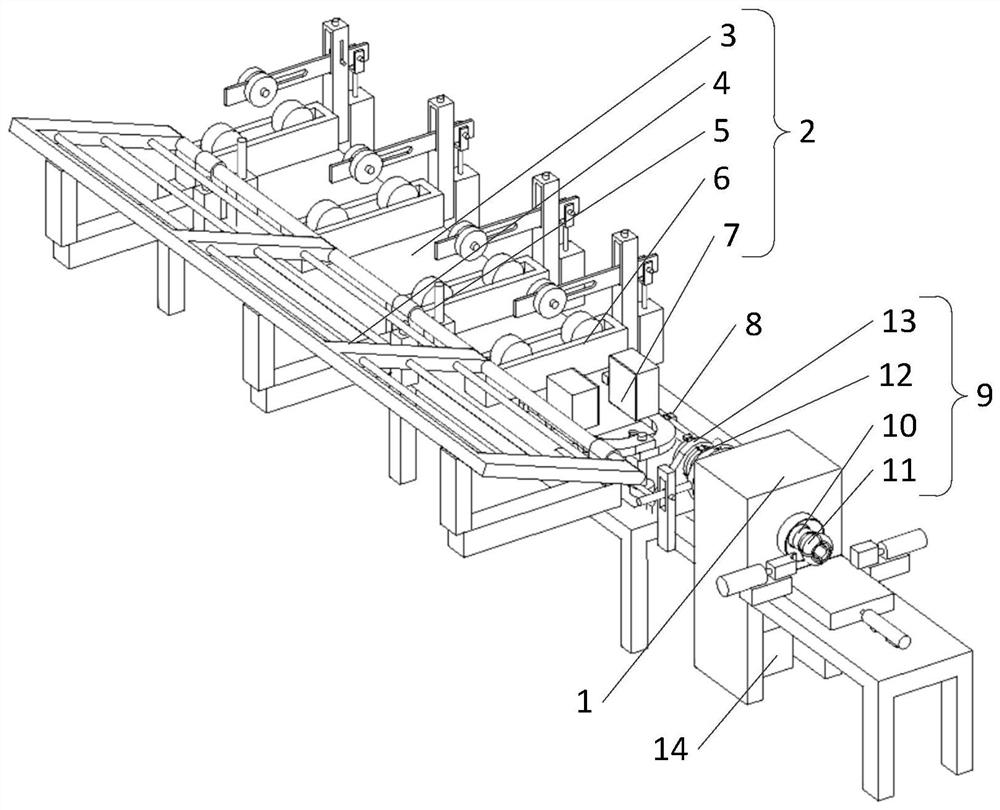

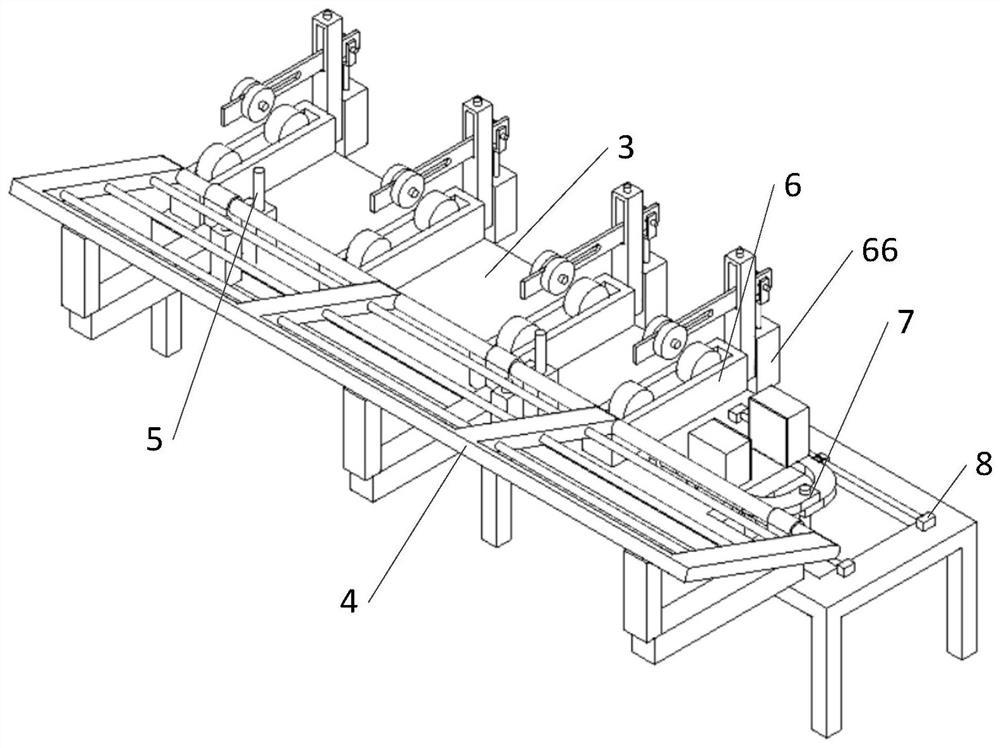

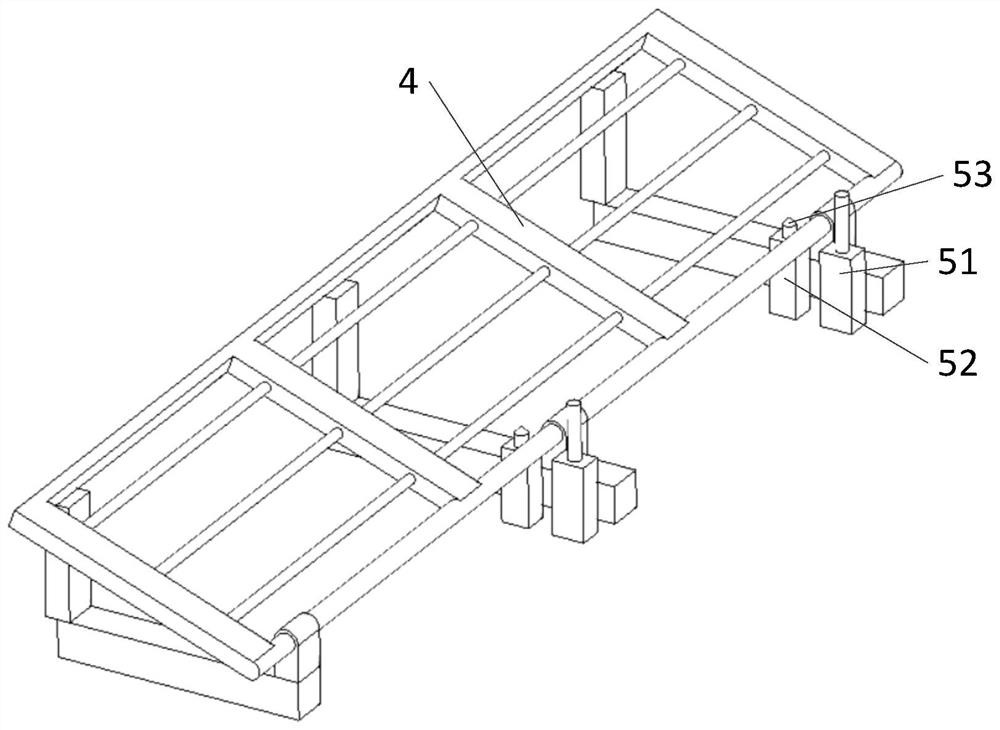

[0038] Such as figure 1 As shown, the automatic pipe cutting machine provided in this embodiment includes a machine tool 1, on which a feeding pipe 1001, a knife rest 1002 and a cylinder group 1005 for controlling the movement of the knife rest 1002 are arranged, and the feeding direction is aligned with the feeding pipe The feeding device 2 and the automatic clamping device 9 installed on the machine tool 1, the feeding device 2 includes a frame 3, a storage rack 4, a distribution device 5, a clamping mechanism 6 and a pushing device 7, and the frame 3 The top is provided with an inclined storage rack 4, and at least one group of feeding device 5 is provided on the frame 3 below the lower end of the storage rack 4, and the frame 3 on one side of the feeding device 5 is provided with a There are multiple clamping mechanisms 6 that hold the pipe material, and they are installed on the top of the frame 3 sequentially along the feeding direction of the pipe material. The rear of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com