Sheet cutting machine

A technology of sheet cutting machine and frame, applied in the directions of lamination auxiliary operation, metal processing, winding strip, etc., can solve the problems of automatic decoupling, film winding shaft jitter, single process, etc., to ensure feeding accuracy and improve tearing. The effect of membrane angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

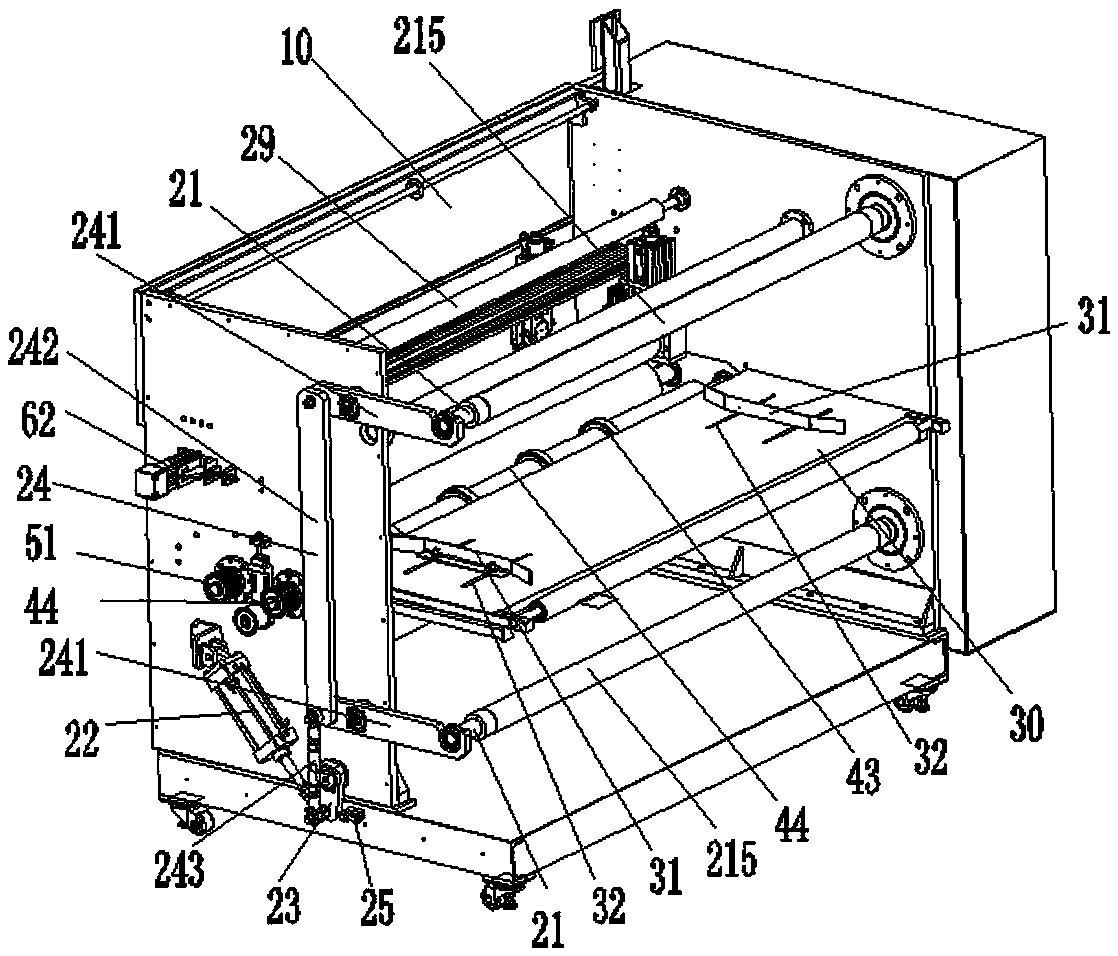

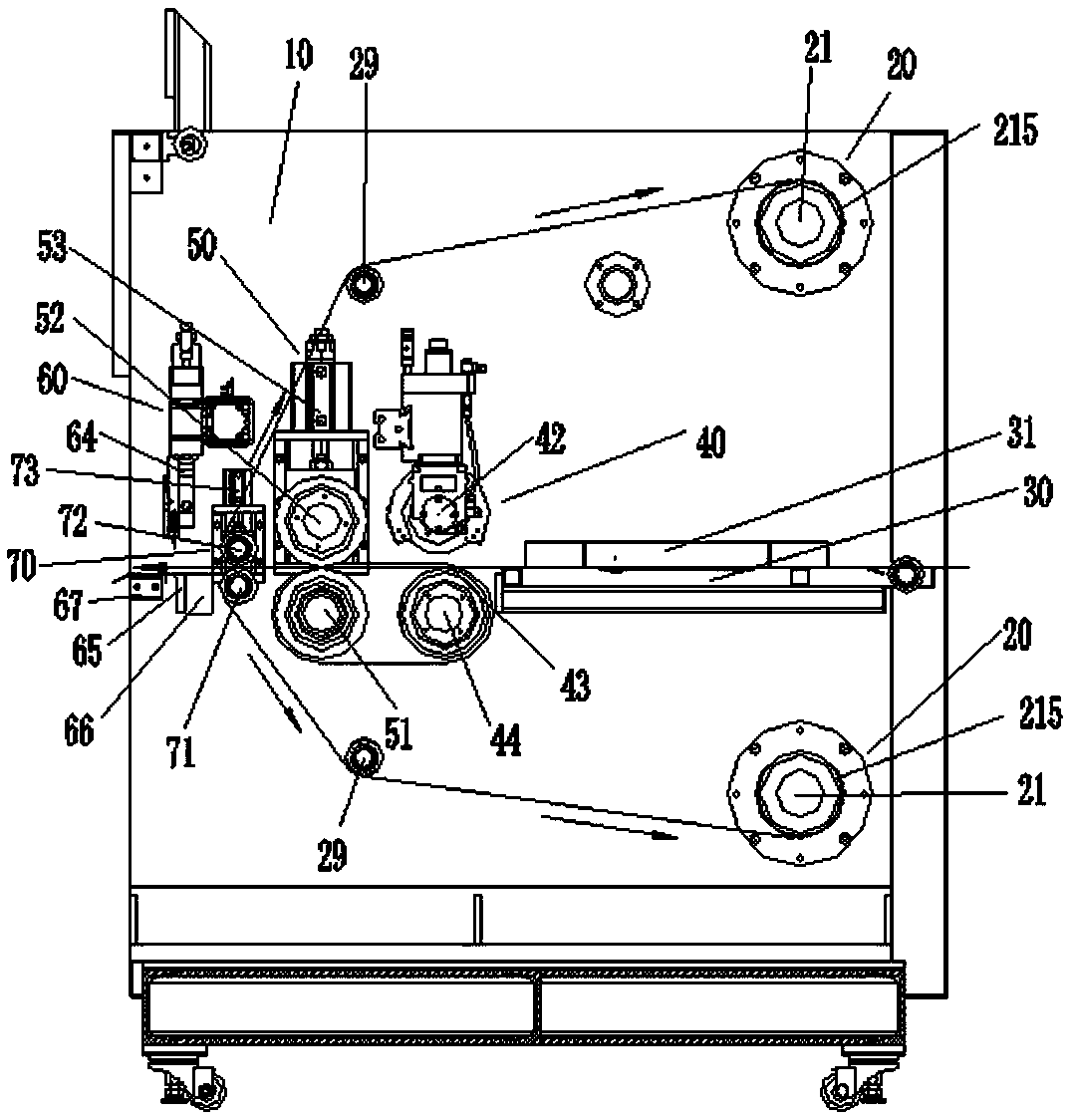

[0038] see Figure 1 to Figure 4 , a slicer, comprising a frame 10, a roll film mechanism 20, and a feeding platform 30 fixed on the frame 10 and arranged in sequence from front to back, a slitting knife mechanism 40, a main drive mechanism 50, a cross-cutting knife Mechanism 60, the film rolling mechanism 20 is fixed on the front part of the frame 10 and is arranged parallel to the upper and lower sides of the feeding platform 30; please refer to Figure 4 , the slitting knife mechanism 40 includes a knife holder 41, a first pneumatic shear knife 42 and a lower cutter drum 44, the two ends of the knife holder 41 are horizontally fixed on the frame 10, and the first Pneumatic shearing knife 42 is fixed on the described knife holder 41, and described following cutter cylinder 44 is fixed on the below of described knife holder 41, and described lower cutter cylinder 44 is connected with described first pneumatic shearing. The corresponding position of the knife 42 is provided w...

Embodiment 2

[0043] The main difference of this embodiment compared with embodiment one is:

[0044] For one, see Figure 5 , the slicer also includes a pressing mechanism 70, the pressing mechanism 70 is arranged between the main driving mechanism 50 and the cross-cutting knife mechanism 60, and the pressing mechanism 70 includes a lower roller 71 and an upper pressing mechanism. Tighten the roller 72, and the upper pressing roller 72 is provided with a pressing force by the first cylinder 73, and the first cylinder 73 is arranged above the upper pressing roller 72; when the main drive mechanism 50 is feeding, the The upper pressing roller 72 is in a loosened state to ensure smooth feeding. When material cutting is required, the upper pressing roller 72 presses the sheet, and the cross-cutting knife mechanism 60 cuts the sheet laterally. After the film is attached to the sheet and passes through the feeding table 30, the slitting knife mechanism 40, the main drive mechanism 50 and the pr...

Embodiment 3

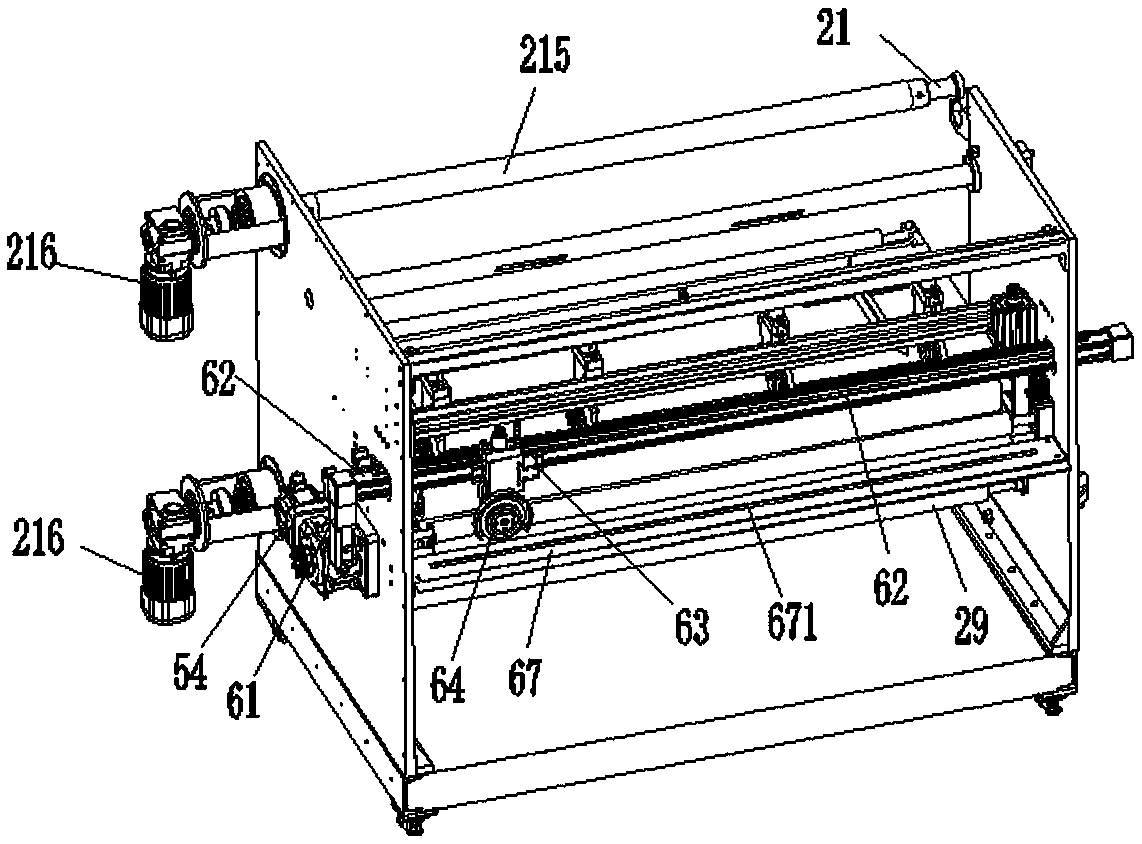

[0051] see Figure 7 to Figure 10 , this embodiment provides a better implementation of the film rolling mechanism, which can overcome the problem that the film rolling shaft 21 shakes or even unhooks due to the pulsation of the air source of the cylinder, so that the swing hook 241 cannot support the shaft end, and there is Potential safety hazards; and when the diameter of the roll film increases, the speed of the roll film is greater than the feeding speed of the main drive mechanism, such as automatic slippage, etc., the details are as follows:

[0052] see figure 1 with Figure 7 , the film roll mechanism 20 includes two film roll shafts 21, a third cylinder 22, a rocker 23, a parallel four-bar linkage mechanism 24 and a limit device 25, and the film roll shaft 21 is sleeved with paper cylinder 215, one end of the third cylinder 22 is installed on one side of the frame 10, and the other end is movably connected with one end of the rocker 23 and the parallelogram mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com