Device and method for positioning and conveying of automatic sheet-fed die-cutting machine

A conveying device, single-sheet technology, applied in the orientation of objects, transportation and packaging, and object separation, etc., can solve the problems of limited paper conveying speed, influence of positioning accuracy, and decreased positioning stability, to ensure the accuracy of paper feeding, realize the Deterministic positioning and high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

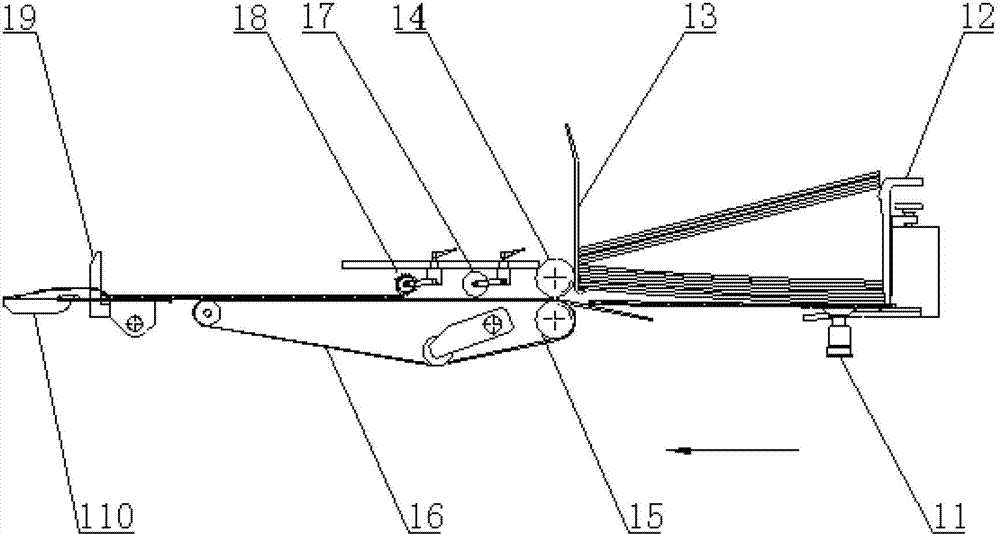

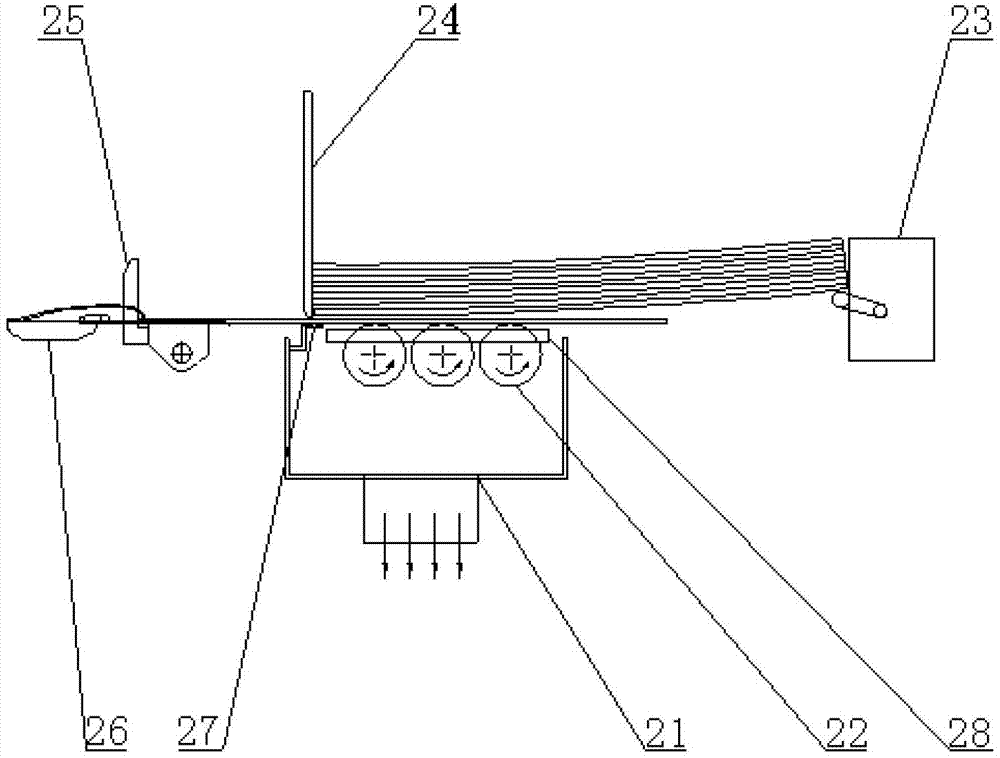

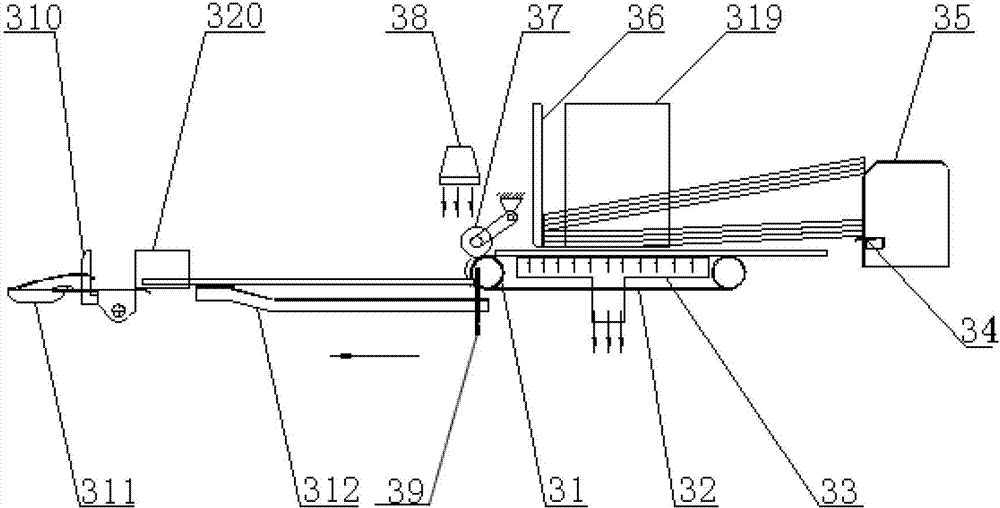

[0055] The positioning and conveying device for sheet-fed automatic die-cutting machine provided by the present invention, such as Figure 3 to Figure 5 As shown, it includes paper storage mechanism, paper feeding mechanism, paper pushing mechanism and positioning mechanism.

[0056] The paper storage mechanism includes a rear paper support frame 35 , a front baffle 36 and a side baffle 319 , the rear paper support 35 is provided with an outstretched rear support 34 , and the side baffle 319 and the front baffle 36 are perpendicular to each other.

[0057] The paper feeding mechanism includes a suction box 33, a first driving mechanism and at least one group of belt transmission mechanisms. In this embodiment, three groups of belt transmission mechanisms are used, and each group of belt transmission mechanisms includes a conveyor belt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com