Supermarket-egg quantitative discharging machine

A technology for discharging machines and eggs, which is applied to furniture or equipment in the service industry, household appliances, applications, etc. It can solve the problems of not being able to stay, consumers are dissatisfied, and reduce shopping enthusiasm, so as to achieve the effect of ensuring the accuracy of feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

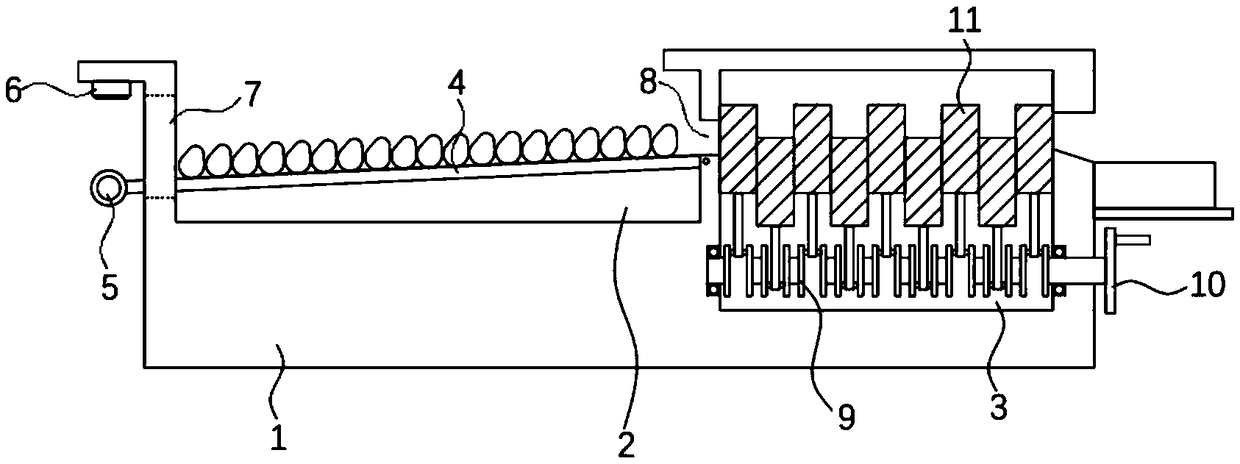

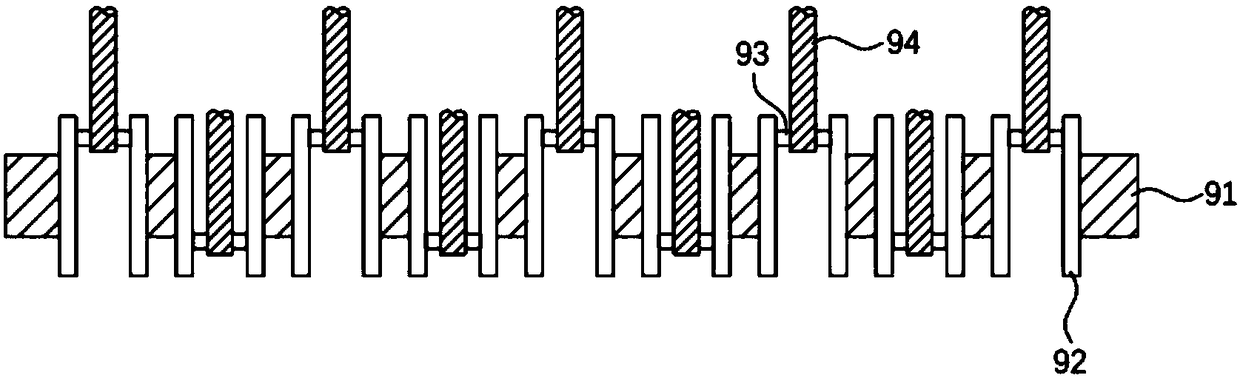

[0027] refer to Figures 1 to 6 , a quantitative discharging machine for eggs in a supermarket, comprising a body 1, a material cavity 2 and a machine cavity 3 are provided in the body 1, the material cavity 2 and the machine cavity 3 are communicated through an opening 8, and the machine cavity 3 is provided with Two crossbars 4 are arranged in parallel, and one end of the crossbar 4 close to the machine chamber 3 is rotatably connected to the bottom end of the opening 8, and the end of the material chamber 2 away from the machine chamber 3 is provided with a limiting groove 7, and the crossbar 4 The end away from the machine cavity 3 passes through the limiting slot 7 and extends to the outside of the machine body 1 .

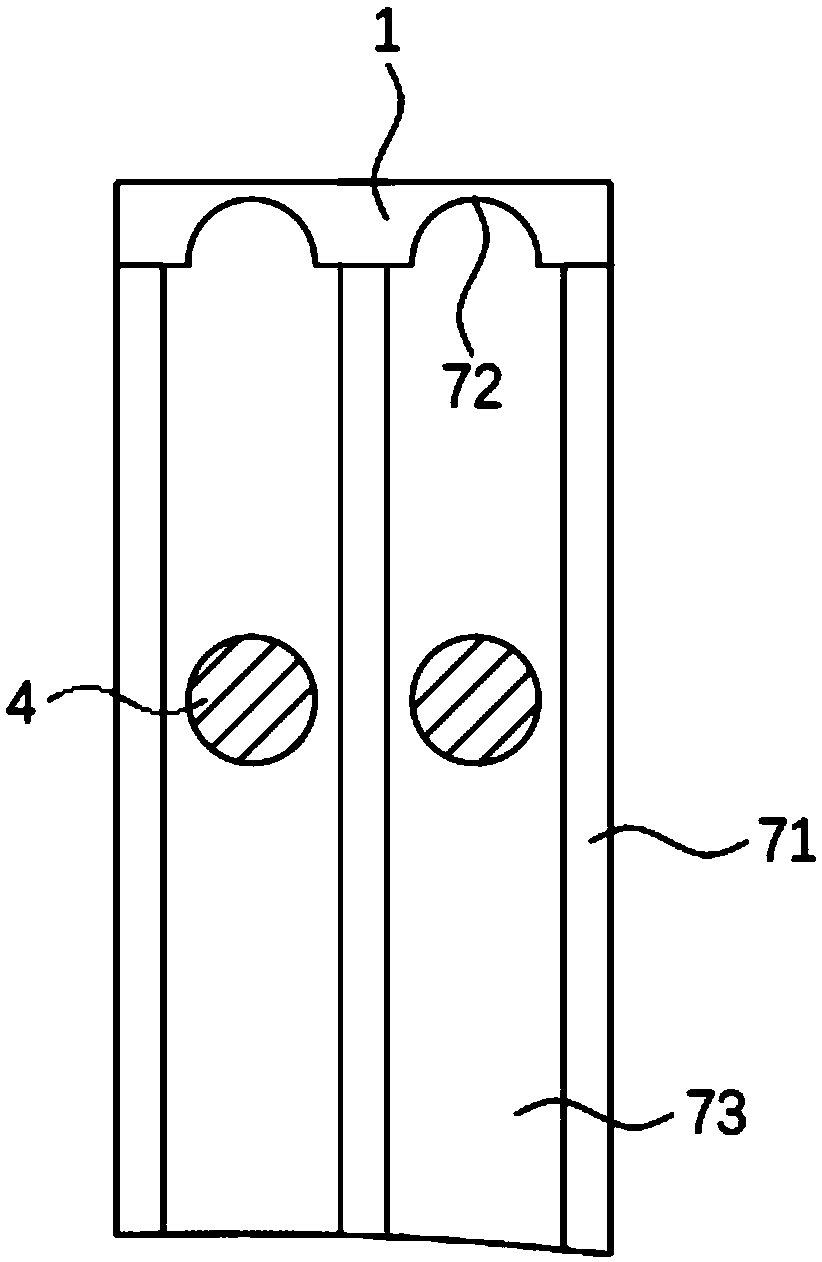

[0028] More specifically, refer to figure 2 The limit groove 7 includes a vertical groove 73 opened on the inner wall of the material cavity 2, and a plurality of limit rods 71 parallel to each other are vertically welded in the vertical groove 73, and th...

Embodiment 2

[0040] refer to Image 6 The difference between the second embodiment and the first embodiment is that the driving mechanism is changed to a stepper motor 12, a controller 13 and a control terminal 14, and the operation is performed through the control terminal 14, and the control terminal 14 can be a capacitive touch screen, and the control terminal 14 will The generated electrical signal is fed back to the controller 13, and the controller 13 can use a 51 single-chip microcomputer to further control the stepping motor to operate a suitable number of turns to make a quantitative egg discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com