Multi-station automatic lamination equipment

A film lamination equipment, multi-station technology, applied in the directions of external support, transportation and packaging, winding strips, etc., can solve the problems of low lamination efficiency, inability to guarantee the accuracy of the feeding position, and inability to ensure that the film is free from wrinkles and bubbles, etc. The effect of feeding accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the present invention more obvious and understandable, the specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

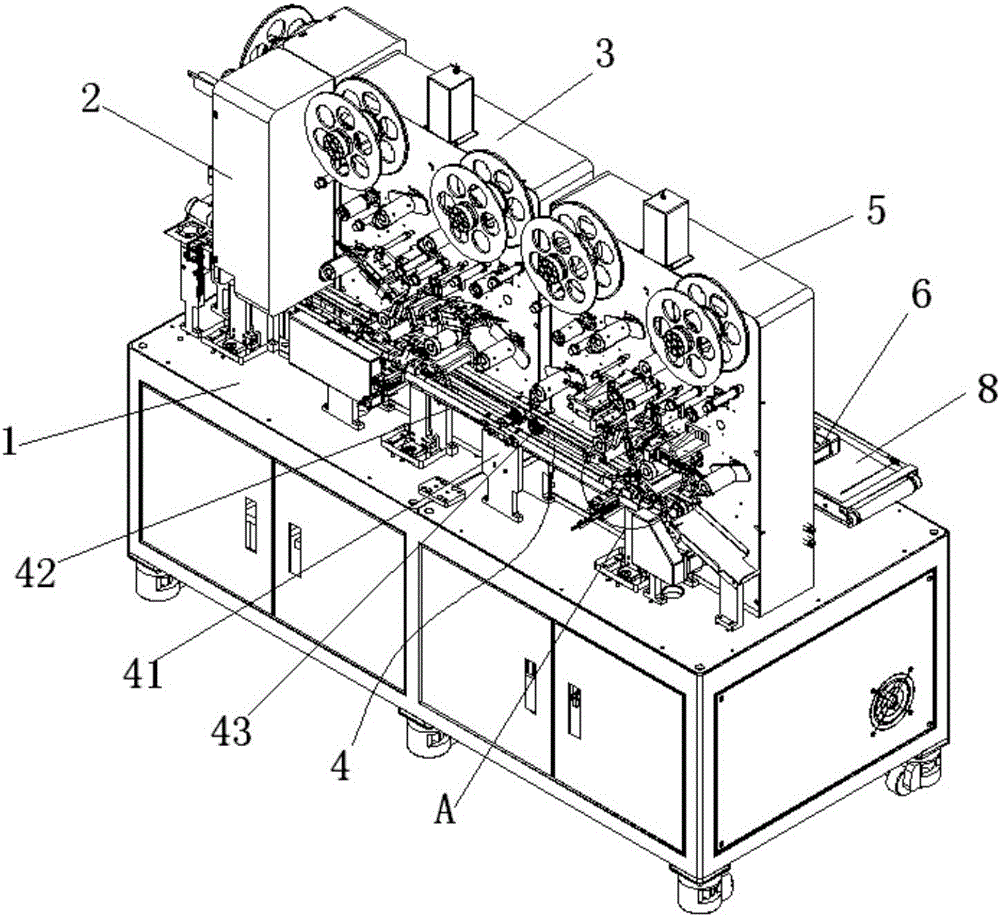

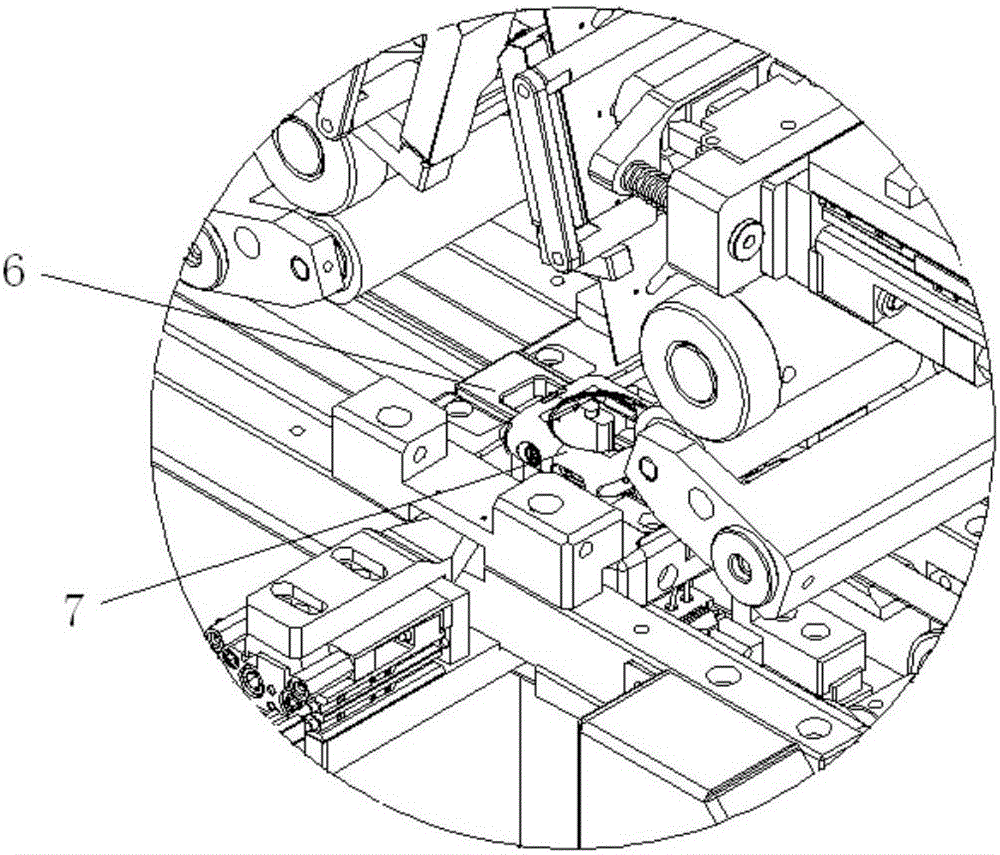

[0032] Such as figure 1 and figure 2 As shown, a multi-station automatic film sticking equipment includes an operation platform 1, a film sticking module 2 on the top surface, a film sticking module 3 on the left and right side I positions, a film sticking module 5 on the left and right sides II position on the operating platform, and a product delivery flow Road 4;

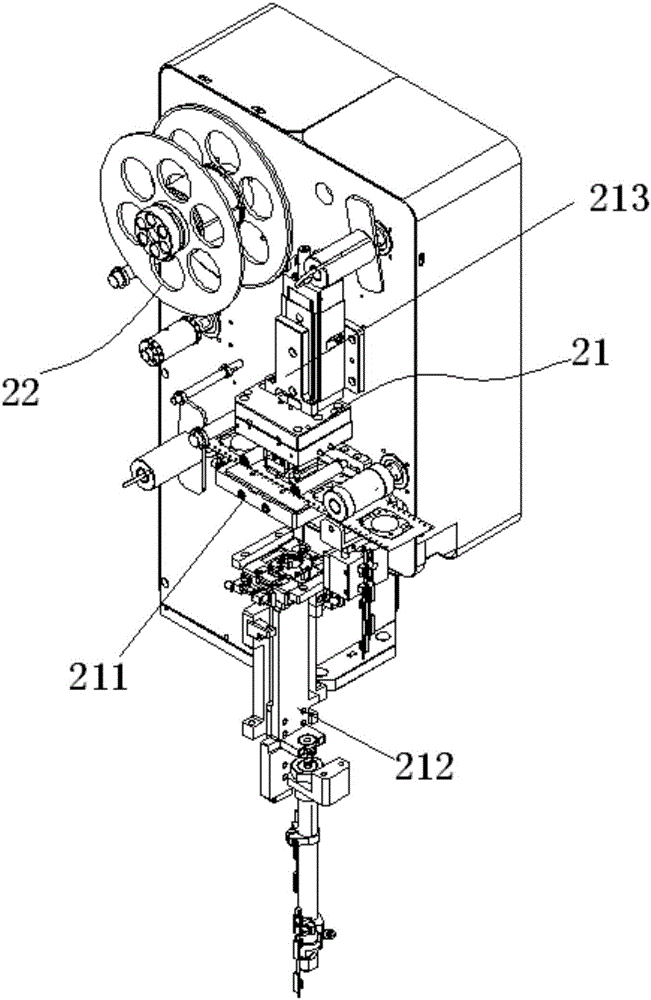

[0033] see image 3 , Figure 4 and Figure 5 , the top surface position film sticking module includes a top surface position film sticking device 21 and a top surface position feeding device 22, and the top surface position film sticking device includes a horizontally arranged top surface position bonding carrier 211, which is located on the top surface position The top surface position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com