Numerical control lock cylinder combination machine

A combined machine and lock cylinder technology, which is applied in the direction of metal processing machinery parts, large fixed members, clamping, etc., can solve the problems of difficult to meet high-precision product requirements, low precision and efficiency, and achieve automation and increase production efficiency , Improving processing efficiency and ensuring the effect of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

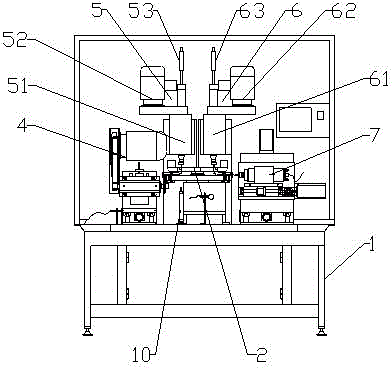

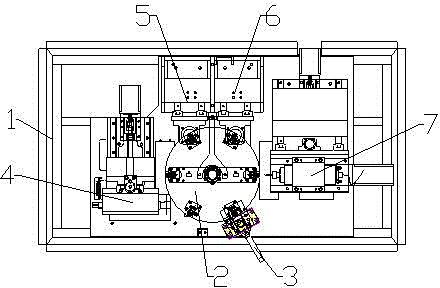

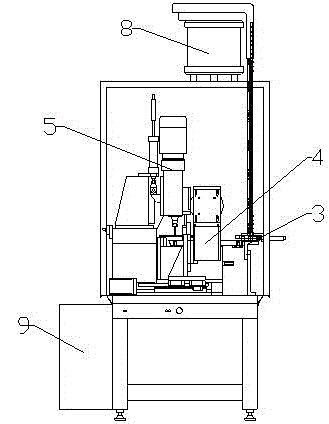

[0037] Accompanying drawing is the specific embodiment of the present invention. Such as Figure 1 to Figure 3 As shown, this kind of CNC lock cylinder combination machine is controlled by PLC control system 9, and it includes a frame 1, on which a clamp assembly 2 is arranged, and an automatic feeding assembly is arranged around the clamp assembly 2 on the frame 1. 3. Groove milling mechanism assembly 4, plane mechanism assembly 5, chamfering mechanism assembly 6 and drilling mechanism assembly 7, and the vibrating plate 8 is connected above the automatic feeding assembly 3, wherein:

[0038] Such as Figure 10 , 11 , shown in 12, automatic feeding assembly 3 comprises feed support 31, and feed support 31 can adjust height, is provided with feed base plate 32, blanking bar 33 and feed block 34, feed base plate 32 at feed support 31 upper ends Pushing cylinder 36 is provided on the top, feeding block 34 is connected with feeding cylinder 37, and feeding block 34 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com