Parallel double-rotor pneumatic conveying feeder

A pneumatic conveying and double-rotor technology, which is applied in the direction of conveyors, conveying bulk materials, transportation and packaging, etc., can solve the problems of inflexible air regulation, insufficient equipment feeding capacity, and low utilization of equipment space. And the configuration mode is flexible, the effect of improving equipment operation efficiency and improving filling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

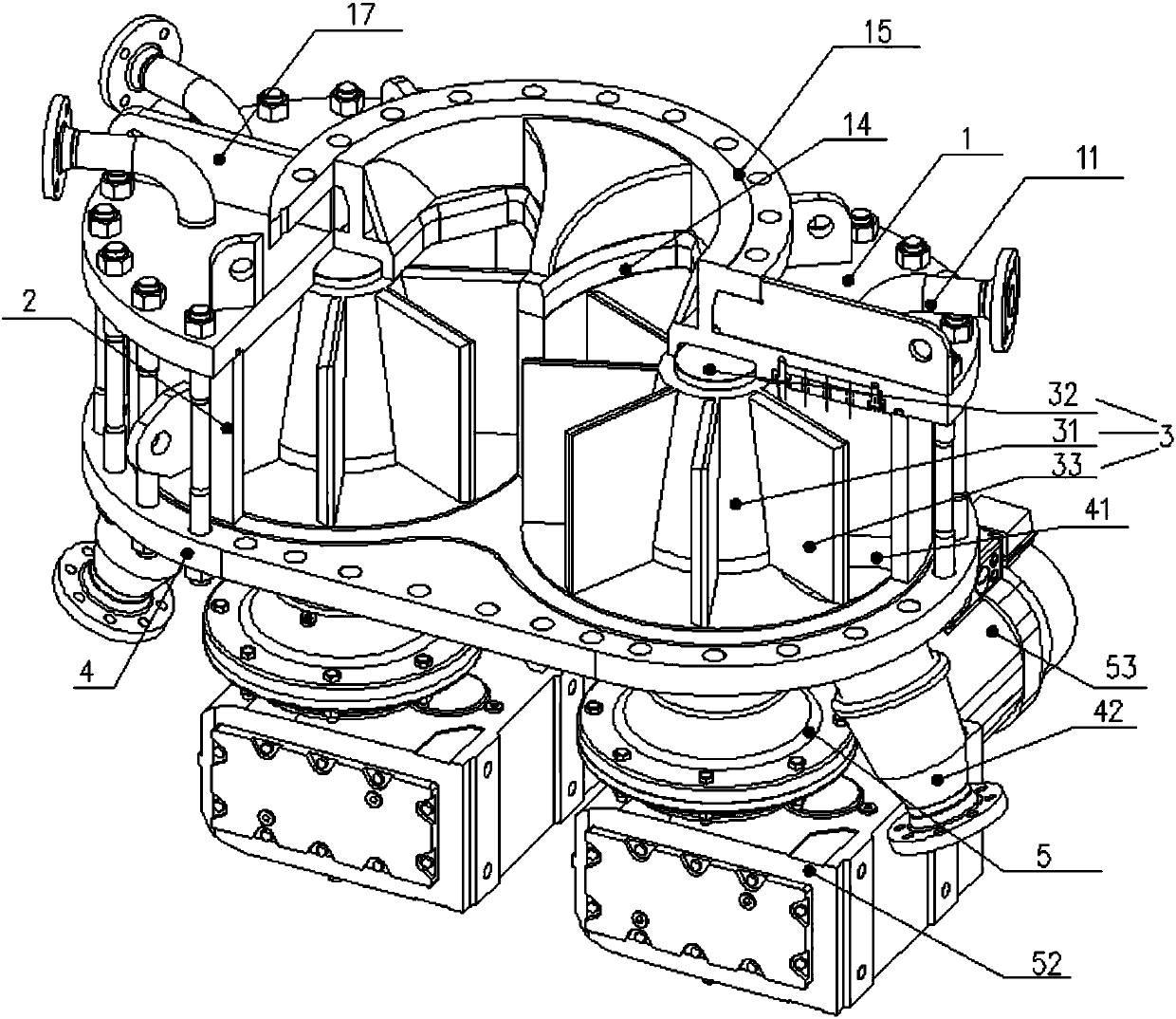

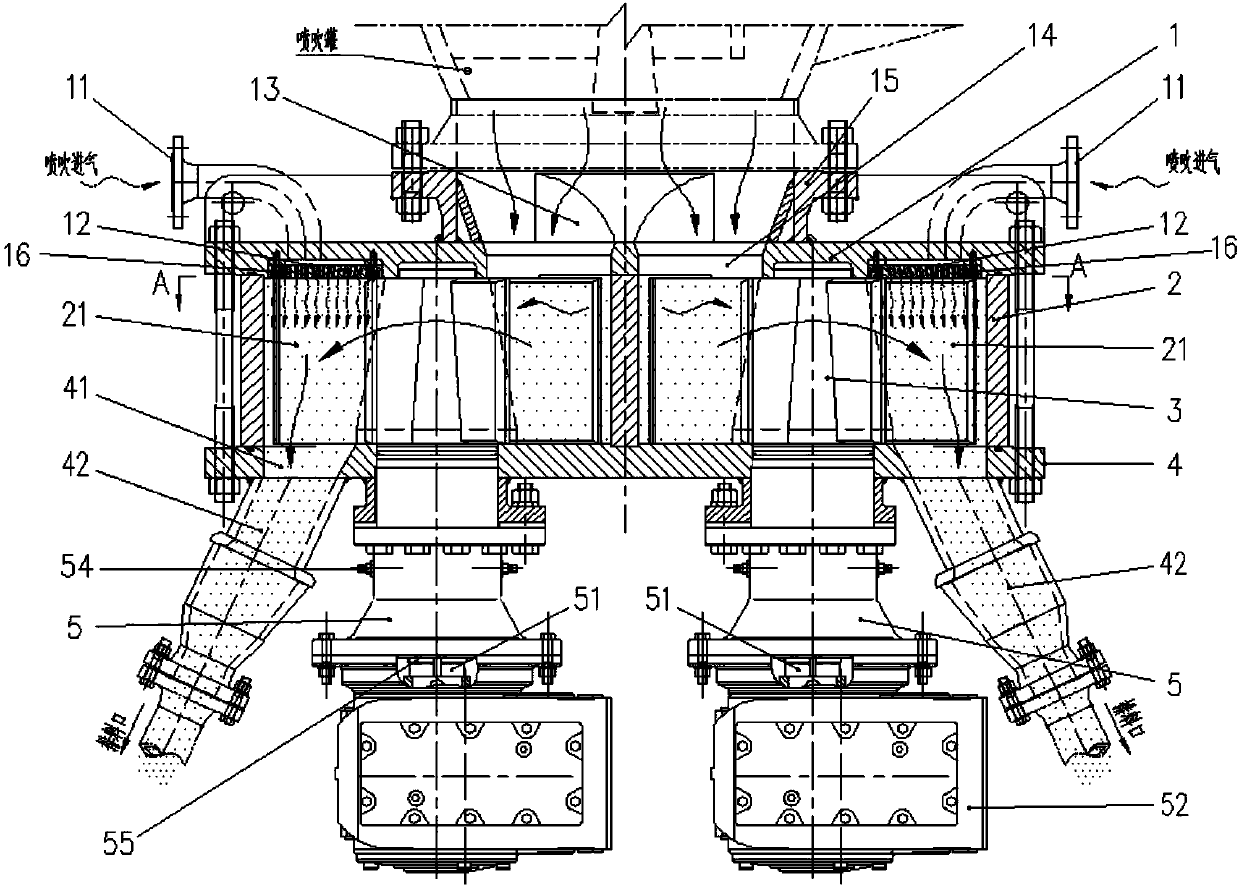

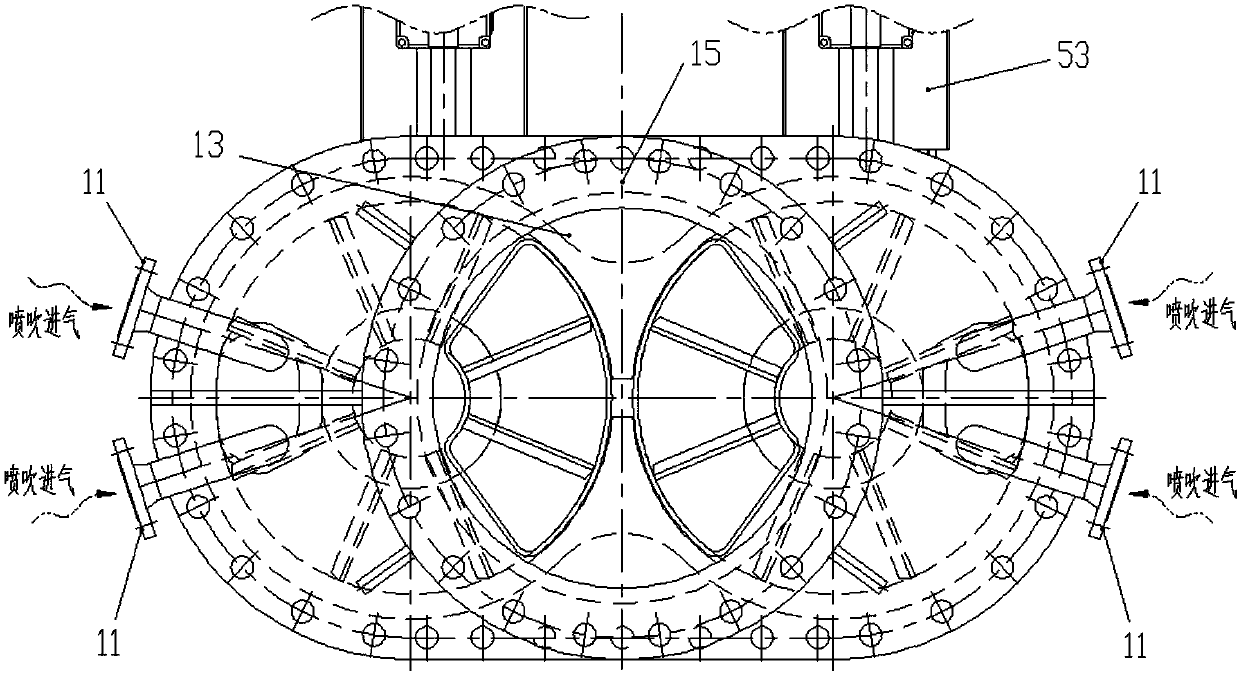

[0032] Such as Figure 1~4 , a parallel double-rotor pneumatic conveying feeder, including a top cover 1, an intermediate casing 2, a bottom plate 4, and a sealed bearing seat 5 arranged sequentially from top to bottom; the middle casing 2 and the top cover 1 and bottom plate 4 A closed impeller chamber 21 is formed, the impeller chamber 21 is provided with an impeller 3, the rotating hub 32 of the impeller 3 is connected with the upper part of the rotating shaft 51 in the sealed bearing seat 5, and the lower part of the rotating shaft 51 is connected with the The drive control system is connected, and it is characterized in that: the impeller chamber 21 and the impeller 3 have two independent side-by-side arrangements; the middle part of the top cover 1 is provided with a feed port 14 communicating with the two impeller chambers respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com