Special mounter for shielding cap

A placement machine and shielding cover technology, which is applied in the field of special placement machines for shielding covers, can solve the problems of stability and precision that are difficult to meet the mounting accuracy, low precision, and large identification errors of shielding covers, so as to maintain the synchronization of suction nozzles Workability, ensure feeding accuracy, and improve placement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. Those skilled in the art can also obtain other drawings based on these drawings without creative work.

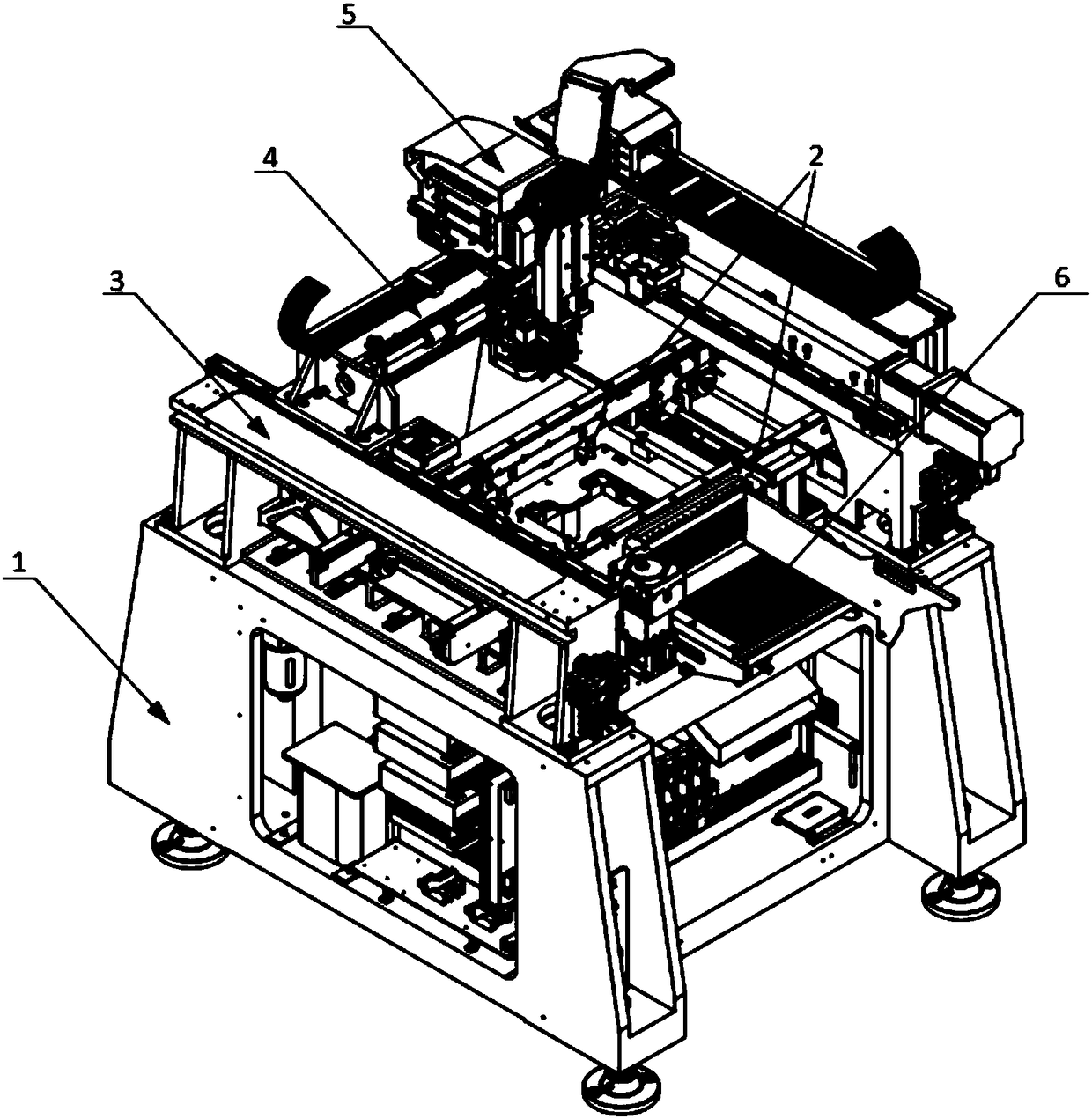

[0040] Such as Figure 1 to Figure 7 As shown, a special mounter for shielding covers includes a main body frame 1 and a PCB transmission assembly 2 arranged on the main body frame 1, a Y-axis arch assembly 3, an X-axis arch assembly 4, a placement head assembly 5, Feeding platform 6,

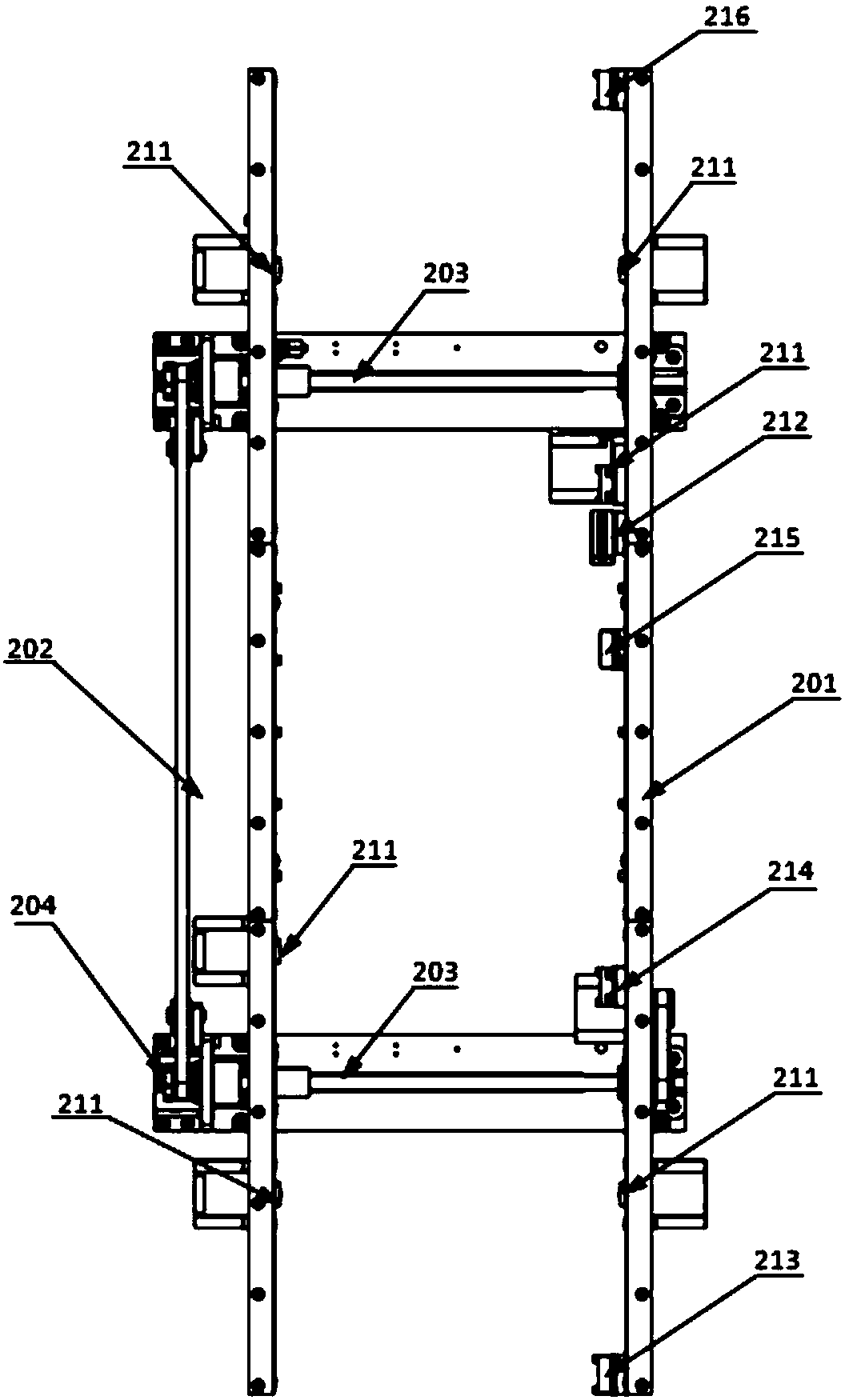

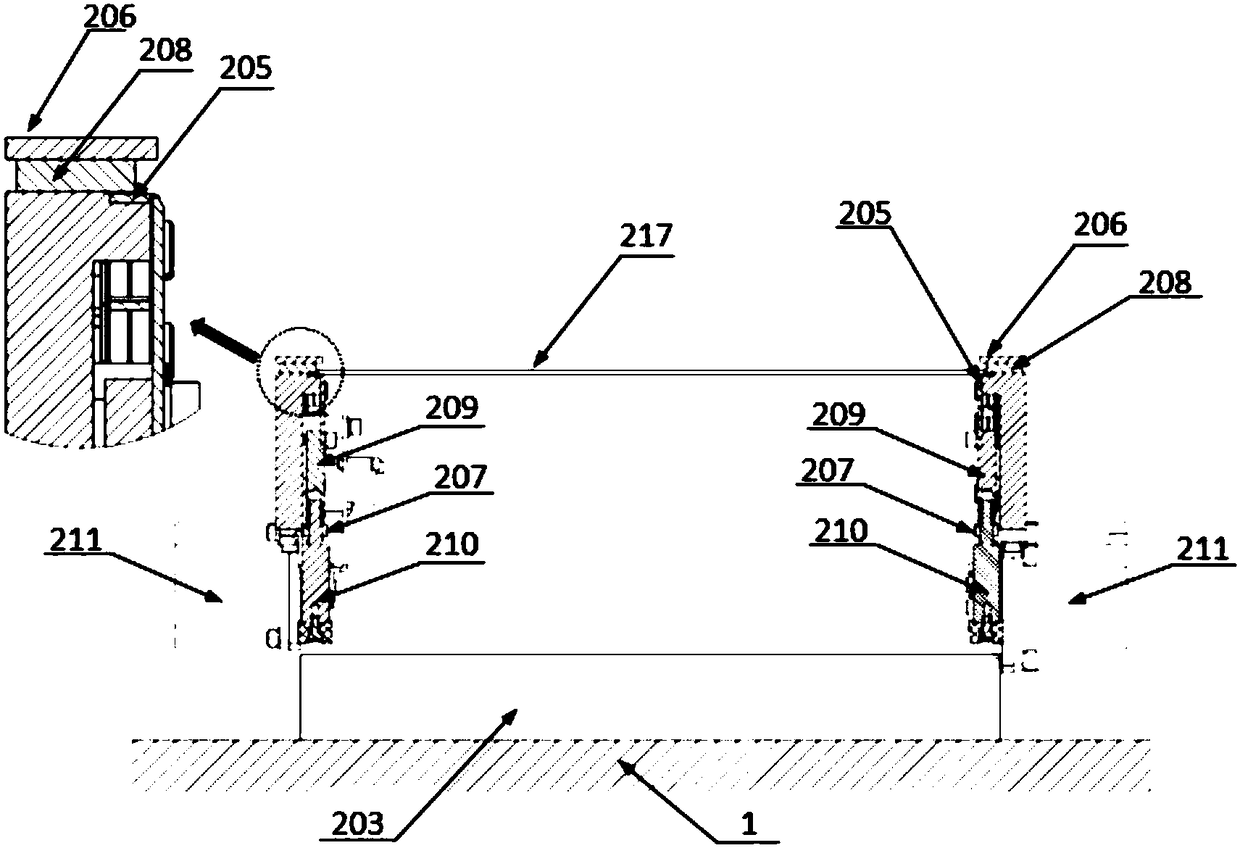

[0041]The PCB transfer assembly 2 is arranged in the middle of the top of the main frame 1, and the PCB transfer assembly 2 includes a fixed side 201 and a movable side 202,

[0042] The fixed side 201 is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com