Control method for variable pitch automatic lubricating system of megawatt wind power generator unit

An automatic lubrication, wind turbine technology, applied in the control of wind turbines, engine lubrication, wind power generation, etc., can solve problems such as large influence, affecting the effect of lubrication, deviation of calculation results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Such as figure 1 As shown, a control method of a megawatt-level wind turbine pitch automatic lubrication system provided by the present invention includes the following steps:

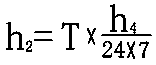

[0033] Step 1: After the system is powered on and initialized, set a lubrication time period h 4 And the lubrication time h required by the slurry system in a lubrication time period 2 , set the time h of each forced lubrication 3 and the forced lubrication interval h 5 ;

[0034] Step 2: Perform normal lubrication, that is, when it is detected that the pitch motor is working, the automatic lubrication system will lubricate the pitch system, and when it is detected that the pitch motor is not working, the pitch system will not be lubricated;

[0035] Step 3: At the end of the lubrication time period, end the normal lubrication, and count the normal lubrication time h of the automatic lubrication system in this lubrication time period 1 ;

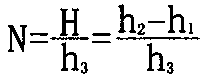

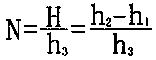

[0036] Step 4: Determine the normal lubrication t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com