Single-source multi-way distributive automatic lubricating system

An automatic lubrication and distributed technology, applied in the direction of engine lubrication, engine components, mechanical equipment, etc., can solve problems affecting production operations, lack of lubrication technology, time-consuming and labor-intensive problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

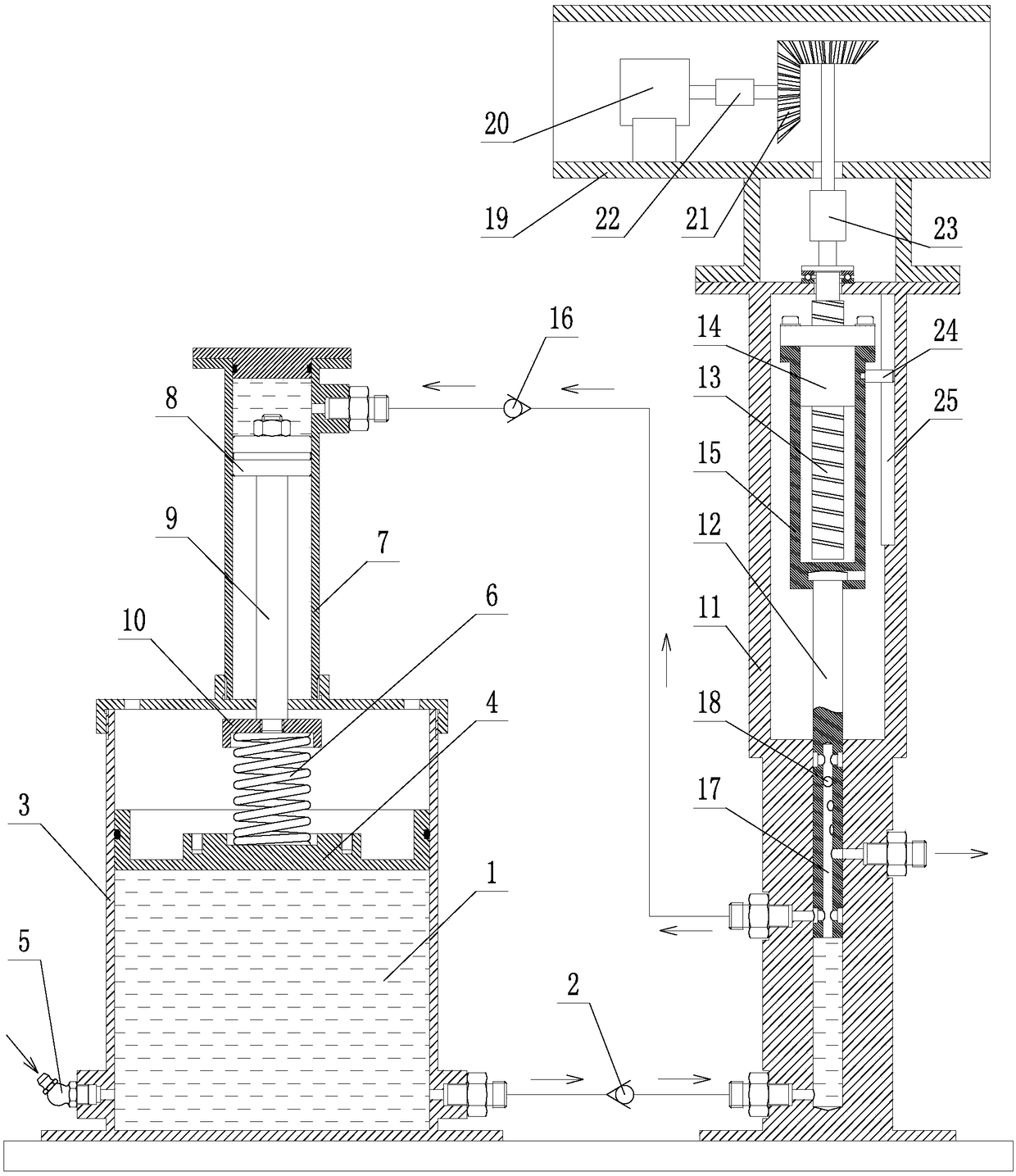

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] Such as figure 1 As shown, a single-source multi-channel distributed automatic lubrication system includes an oil storage cylinder, an oil storage output loading cylinder, an oil injection cylinder and an oil injection output drive box; the oil storage cylinder is used to store grease 1, and the grease outlet of the oil storage cylinder It is connected with the grease inlet of the oil injection cylinder through a pipeline, and a first check valve 2 is installed on the pipeline, and the inlet end of the first check valve 2 is connected with the grease outlet of the oil storage cylinder. The outlet end of the oil injection cylinder is connected with the grease inlet of the oil injection cylinder; the oil storage cylinder outputs grease 1 to provide power through the oil storage output loading cylinder; the oil injection cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com