High-pressure dry oil pneumatic control valve

An oil-gas and high-pressure technology, which is applied in the field of high-pressure dry oil-gas control valves, can solve problems such as poor reliability, limited electromagnetic force, and slow response speed, and achieve high reliability, fast response speed, and high-frequency work requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

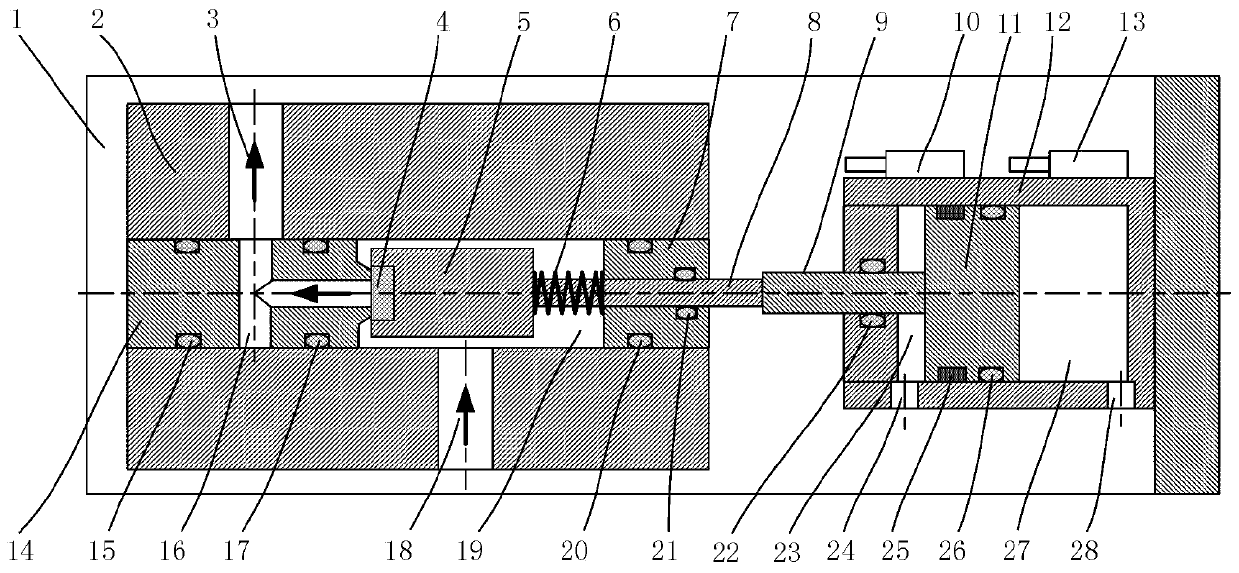

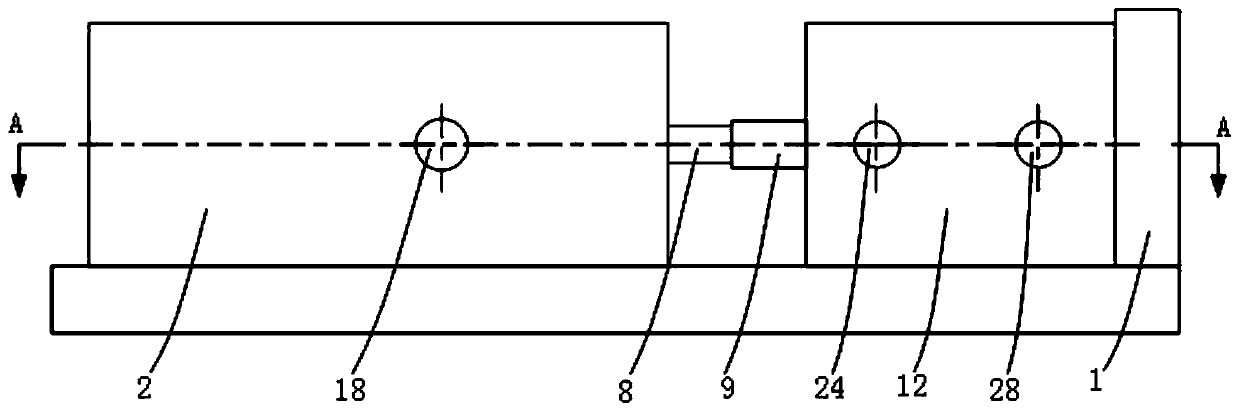

[0022] from Figure 1-2 It can be seen that a high-pressure dry oil and gas control valve in this embodiment includes a base 1, the base 1 is an L-shaped structure, the surface of the base 1 is provided with a valve body 2, and a central through hole is opened inside the valve body 2. A valve seat 14, a valve core 5 and a sealing end cap 7 are respectively arranged in the central through hole, the sealing end cap 7 is clamped in the central through hole of the valve body 2, and a fourth valve is arranged between the sealing end cap 7 and the valve body 2. The sealing ring 20, the cavity formed between the valve body 2, the valve core 5 and the sealing end cover 7 is the valve cavity 19, and the first sealing ring 15 and the second sealing ring 17 are respectively arranged between the valve seat 14 and the valve body 2 , the valve seat 14 is provided with a T-shaped through hole 16, the surface of the valve body 2 is provided with an oil outlet 3, one side of the oil outlet 3 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com