Control method for automatic lubrication system of pitch bearing for wind turbine

A technology for pitch bearings and wind turbines, applied in the control of wind turbines, engine lubrication, wind power generation, etc., can solve problems such as waste of lubricating oil, inability to lubricate, and wheel hub pollution, and achieve less grease usage and better lubrication effect. , the effect of small power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

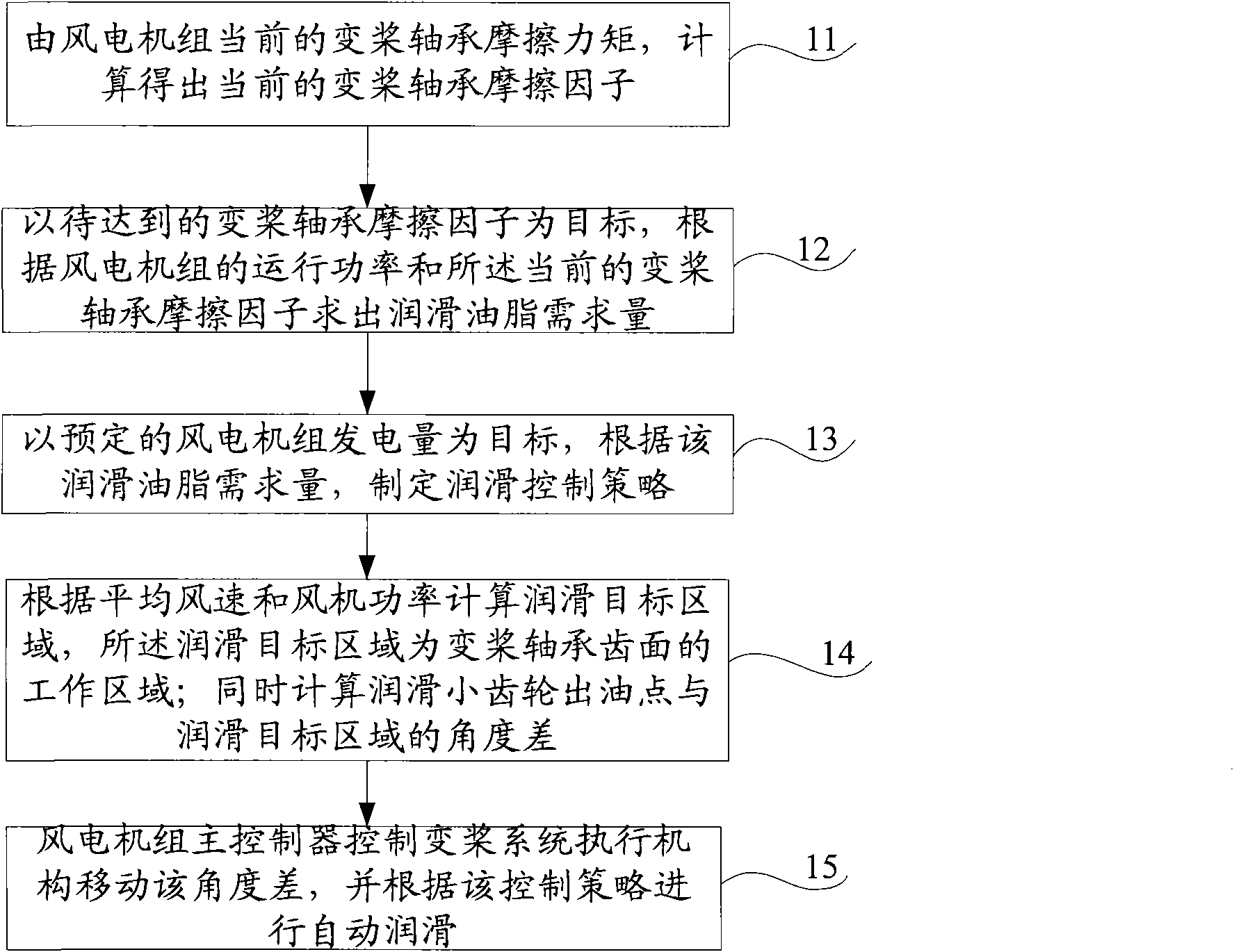

[0047] Such as figure 1 As shown, the control method of the practical pitch bearing automatic lubrication system of the wind turbine according to the present invention includes the following steps:

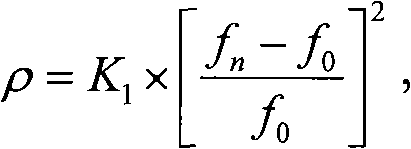

[0048] Step 11: Calculate the current pitch bearing friction factor from the current pitch bearing friction torque of the wind turbine;

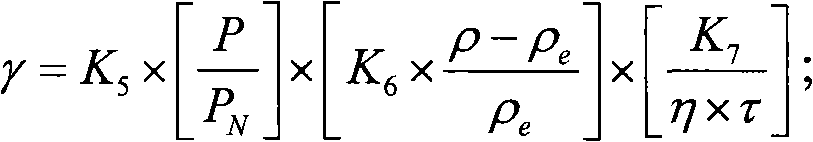

[0049] Step 12: taking the pitch bearing friction factor to be achieved as the target, and calculating the demand for lubricating grease according to the operating power of the wind turbine and the current pitch bearing friction factor;

[0050] Step 13: Taking the predetermined power generation of wind turbines as the target, formulate a lubrication control strategy according to the demand for lubricating grease;

[0051] Step 14: Calculate the lubrication target area according to the average wind speed and fan power, and the lubrication target area is the working area of the pitch bearing tooth surface; at the same time, calculate the angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com