Locomotive auxiliary engine self-lubrication method and system

An automatic lubrication and locomotive technology, which is applied in the direction of engine lubrication, lubricating parts, mechanical equipment, etc., can solve the problems of unsuitable automatic lubrication of locomotive auxiliary equipment, etc., and achieve the effect of improving service life and ensuring driving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

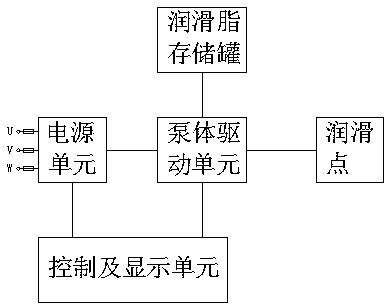

[0034] An automatic lubrication system for locomotive auxiliary equipment, including a power supply unit, a control and display unit, a pump body drive unit, and a grease storage tank, wherein the input end of the power supply unit is connected to the power supply of the locomotive auxiliary equipment, and the output end is connected to the control and display unit and the pump The control and display unit communicates with the pump body drive unit and controls the movement of the pump body drive unit, and the pump body drive unit communicates with the grease storage tank and the lubrication point of the locomotive auxiliary machine.

[0035] The input end of the power supply unit of the locomotive auxiliary machine automatic lubrication system is connected to the junction box of the locomotive auxiliary machine, and the power supply unit is used to obtain AC380V / AC440V power from the junction box, and the control and display unit controls the movement of the pump body drive uni...

Embodiment 2

[0044] The difference between this embodiment and the above-mentioned embodiments is that in this embodiment, the lubrication operation of the locomotive auxiliary equipment is completed manually, and the manual lubrication operation can be performed by setting the lubrication operation to manual mode through the operation interface.

[0045] The above-mentioned embodiment also relates to a method for automatic lubrication of locomotive auxiliary machines, which is realized through the automatic lubrication system of locomotive auxiliary machines. Obtain power and send it to each subsequent unit to make the automatic lubrication system of locomotive auxiliary equipment work. The control and display unit of the automatic lubrication system of locomotive auxiliary equipment controls the pump body drive unit to drive its plunger to suck grease from the grease storage tank and deliver the grease To the lubrication point of each auxiliary machine that needs to be lubricated.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com