Automatic lubrication system for a bearing, and method for operating an automatic lubrication system

An automatic lubrication and lubrication system technology, applied in the direction of engine lubrication, shaft and bearing, lubrication parts, etc., can solve the problems of excessive supply of bearing lubricant, reduce bearing operability, bearing damage, etc., and improve work reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

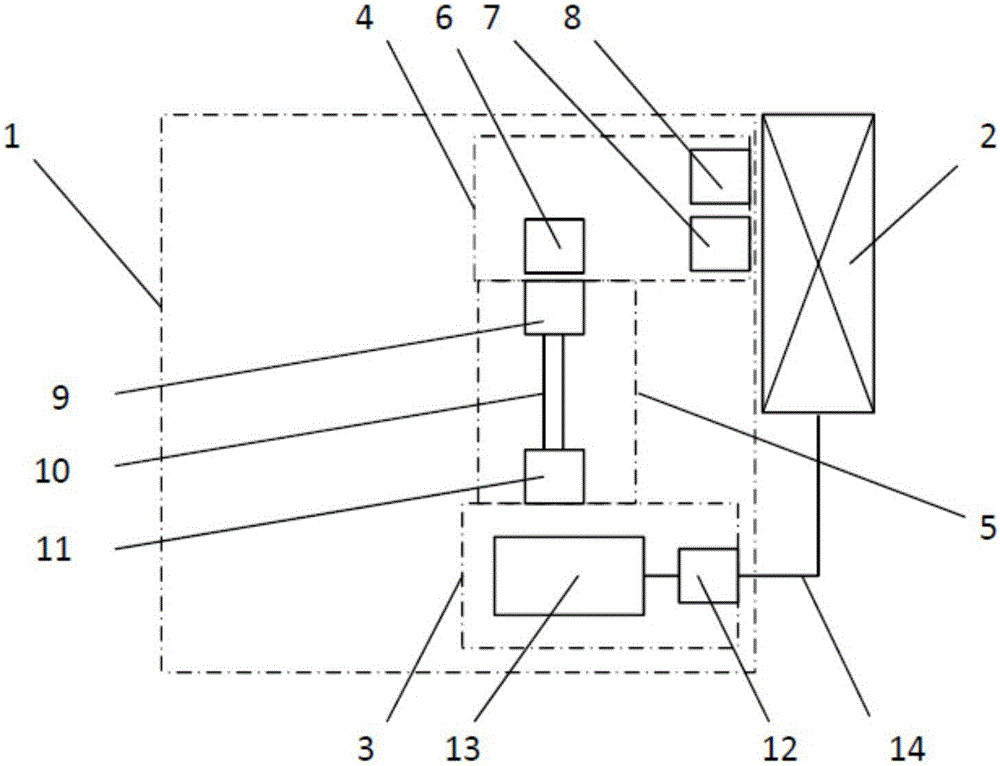

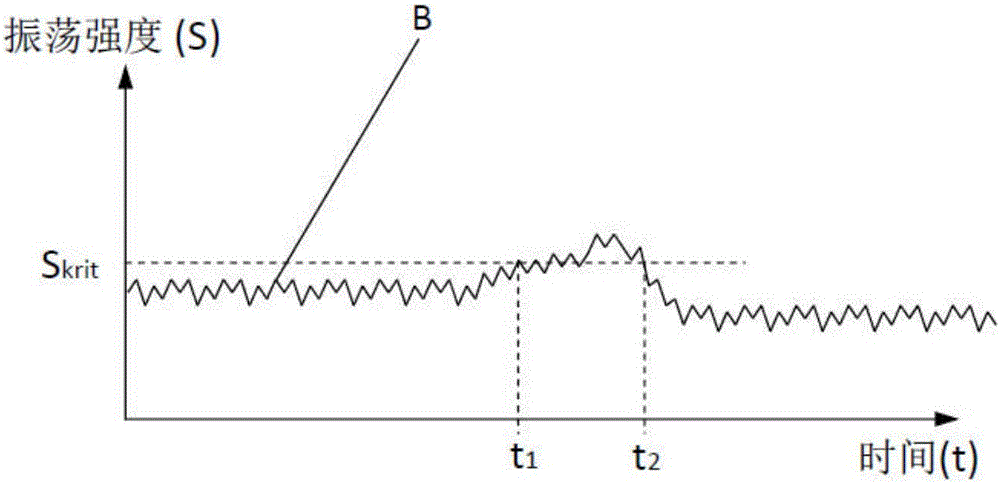

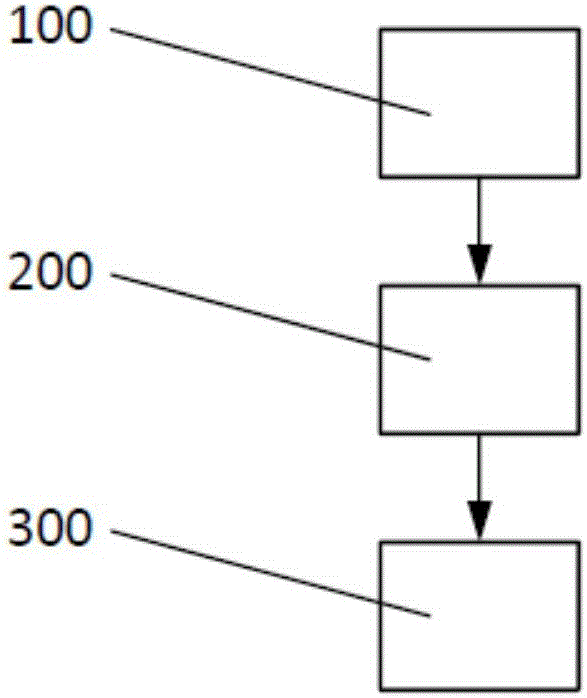

[0060] exist figure 1 The first embodiment of the automatic lubrication system 1 shown schematically in , which automatically fills the bearing 2 with lubricant in a demand-driven manner, has a lubrication device 3 . As an option, the lubrication device 3 has a lubricant storage device 13 and a lubricant pump 12 . The lubricating device 3 is designed to supply a bearing 2 , for example a rotor bearing of a wind turbine, with a lubricant, such as grease. The lubrication system 1 has a detection device 4 for detecting the working state of the bearing 2 . As an option, the detection device 4 can have an acceleration sensor 7, for example, to detect or measure the operating vibration B of the bearing 2 (see figure 2 ). Furthermore, as an option, the detecting device 4 can have a rotational speed sensor 8 for detecting or measuring the bearing rotational speed of the bearing 2 . The rotational speed sensor 8 is, for example, an optical rotational speed sensor. As an option, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com