Method and apparatus for purging air from automatic lubrication systems

An automatic lubrication and gas removal technology, which is applied in the direction of engine lubrication, mechanical equipment, lubricating parts, etc., can solve problems such as the impact of machine productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

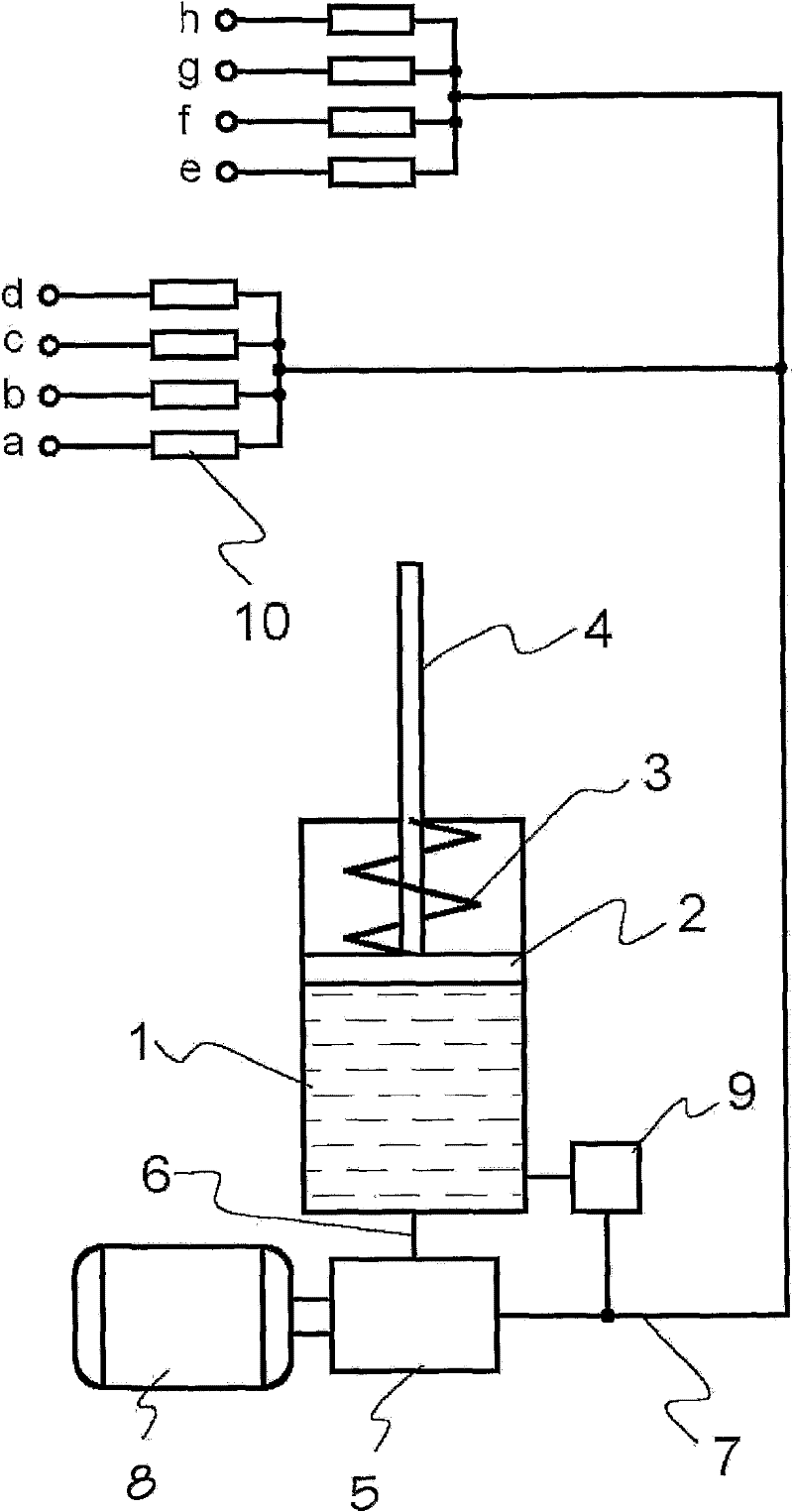

[0042] will now refer to Figure 1 to Figure 4 Describe the basic operation of the different forms of automatic lubrication systems.

[0043] figure 1 A very basic motor driven centralized lubrication system is shown. Lubricating oil is loaded into reservoir 1 . The means for loading the lubricating oil is not shown, but is usually a rotary pump driven manually, electrically or by compressed air. When loaded with lubricating oil, the driven piston 2 is pushed up against the spring 3 . A rod 4 protrudes from the top of the reservoir 1 and provides a visual indication of the amount of lubricating oil in the reservoir.

[0044]The lubricating oil pump 5 has an inlet connection 6 and a delivery line 7 . The pump can be of the single piston type (rotary or reciprocating), and is most often an automatic reciprocating piston pump powered by compressed air. Power is provided by a motor 8, which can be electric, pneumatic, hydraulic or even manual. Vent valve 9 opens when the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com