Automatic-turning slideway type metal circular sawing machine

A slideway type circular saw machine technology, applied in metal sawing equipment, metal processing equipment, sawing machine equipment, etc., can solve the problems of inability to realize conversion, cumbersome operation, slow speed, etc., and achieve fast sawing size conversion and easy operation Easy maintenance and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

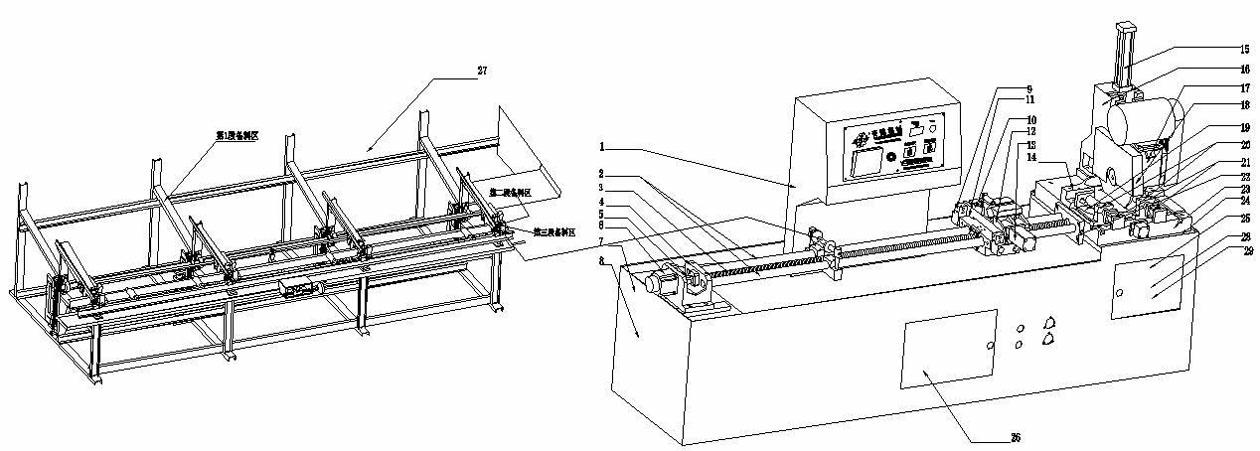

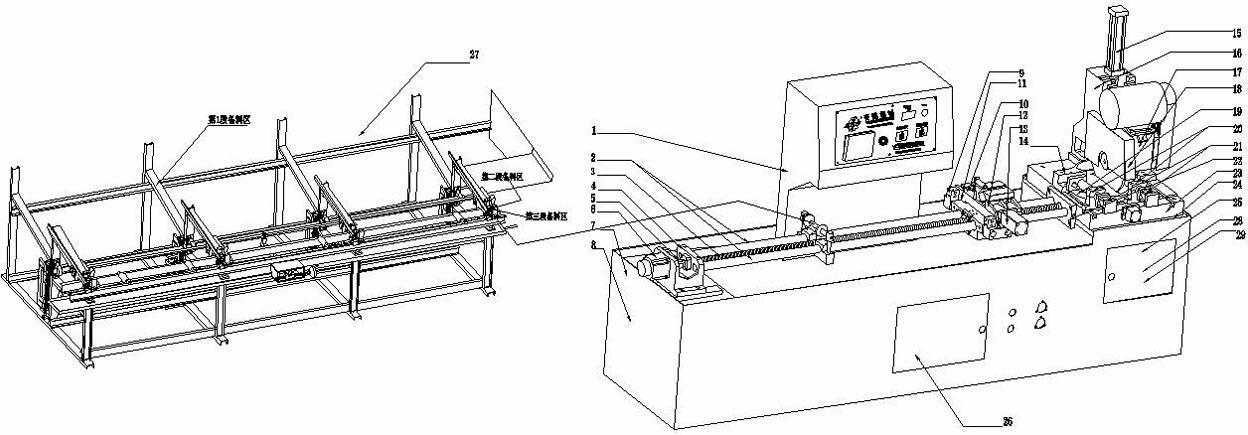

[0020] The present invention will be further described below in conjunction with accompanying drawing and embodiment, as figure 1 As shown, the CNC-400-A automatic corner slide type metal circular saw machine of the present invention includes a fuselage 7, a feeding device installed on the fuselage 7, a knife feeding device, a conjoined seat 4, and a servo motor (6, 29 ) and the electric control box 1, and also includes an automatic material preparation device that realizes automatic feeding and feeding through oil cylinders and sensors; the automatic material preparation device includes a first section of material preparation area, a second section of material preparation area and a third section of material preparation area. CNC-400-A automatic corner slide type metal circular saw machine adopts multi-set gear linkage chassis, super powerful design, motor synchronously drives multiple sets of gears to drive the main shaft, high and low two-speed adjustable speed, stable opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com