Method for processing special-shaped glass with data control

A technology of special-shaped glass and processing method, which is applied to manufacturing tools, metal processing equipment, machine tools suitable for grinding the edge of workpieces, etc. and other problems, to achieve ideal edging effect, ensure personal safety, and improve the effect of edging processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

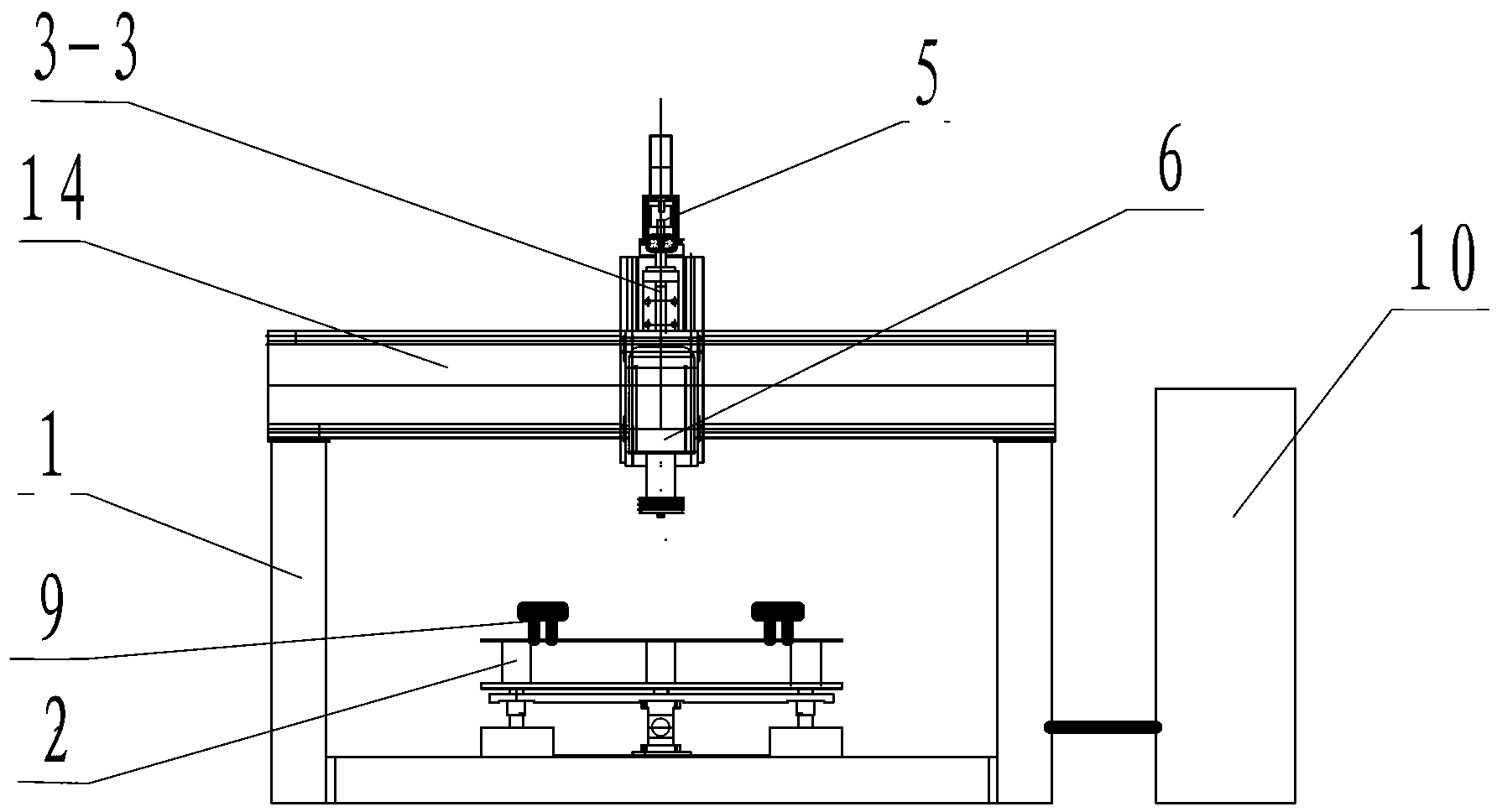

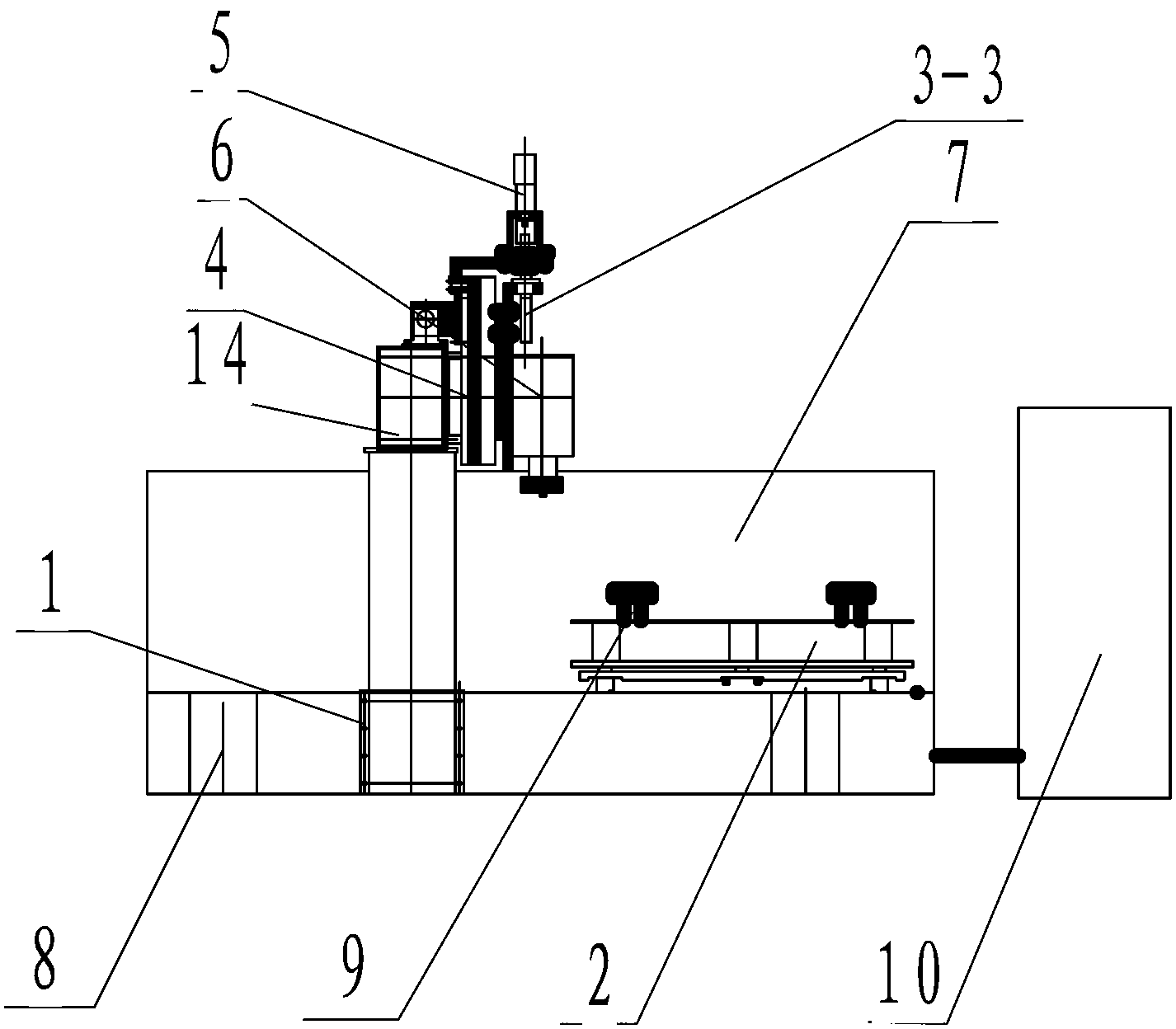

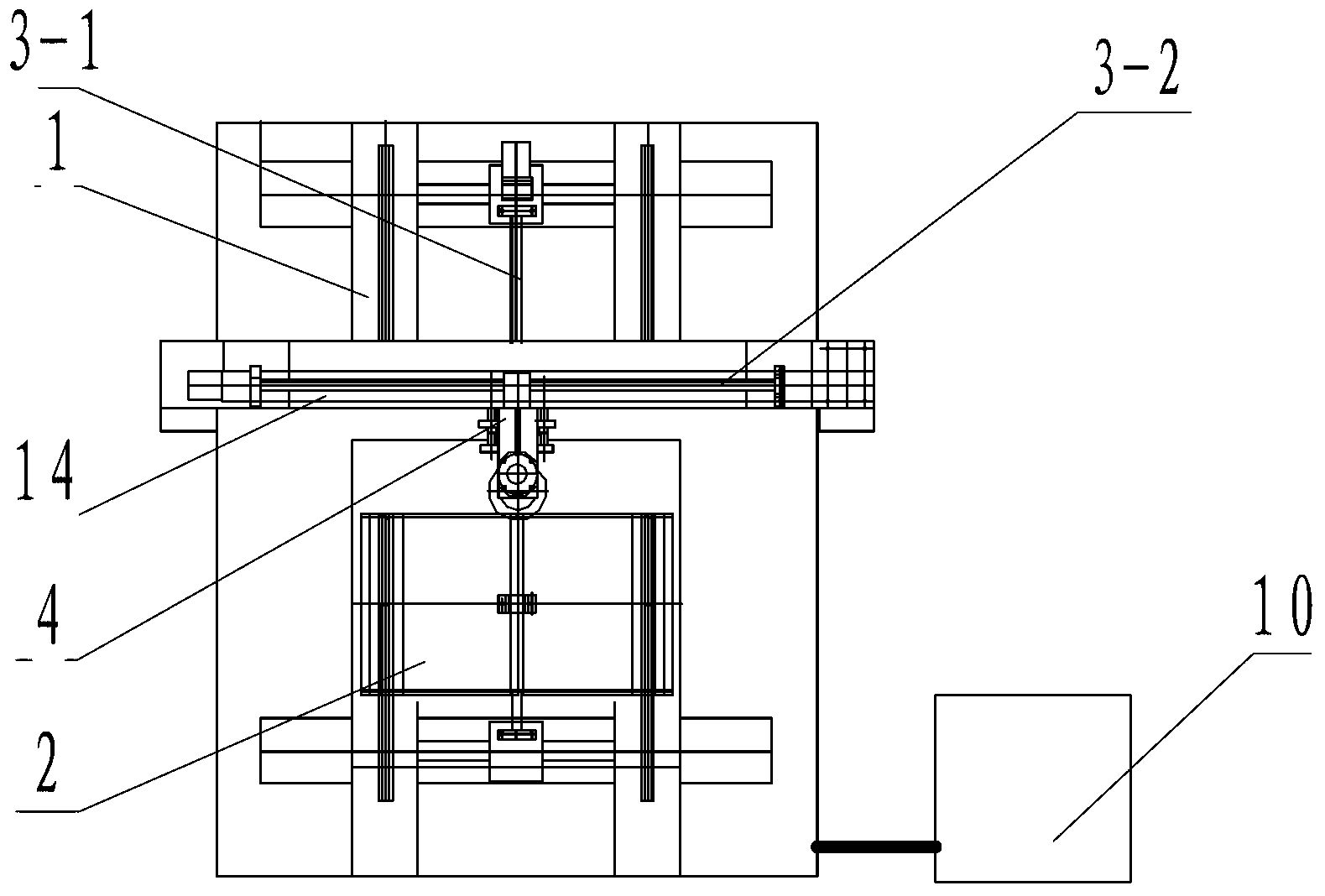

[0025] Fix the glass on the positioning suction plate 9 on the mobile platform 2, correct the glass, and rotate the Y-axis screw 3-1 below the mobile platform 2 to make the mobile platform 2 run along the direction of the Y-axis screw 3-1. Click Y+ and Y- on the interface to move the glass on the mobile platform 2 to the position to be processed along the Y-axis screw 3-1, and the Z-axis screw 3-3 above the up and down step / servo mechanism 5 rotates to make the up and down step / The servo mechanism 5 runs along the direction of the Z-axis lead screw 3-3, click Z+ and Z- on the computer control interface, so that the up and down stepping / servo mechanism 5 drives the grinding head mechanism 6 to run along the direction of the Z-axis lead screw 3-3, and the grinding The grinding head below the head mechanism 6 runs to the same height as the edge of the glass to be ground, and the X-axis screw 3-2 behind the horizontal stepping / servo mechanism 4 rotates to make the horizontal stepp...

Embodiment 2

[0027] Horizontal stepping / servo mechanism 4 leads along the X-axis lead screw 3-2 direction, up and down stepping / servo mechanism 5 leads along the Z-axis lead screw 3-3 direction and mobile platform 2 along the Y-axis lead screw 3- The lead in direction 1 can be set according to the processing standard. The lead calculation formula is: lead = pitch multiplied by the number of turns, the lead is 6-15 cm, and the grinding head mechanism 6 is in the state of rough grinding, fine grinding and polishing The rotating speed can be set according to the processing standard, and the rotating speed is 2000-3200 rpm.

Embodiment 3

[0029] After the grinding wheel under the grinding head mechanism 6 is disassembled, a drill bit or a cutter can be installed. After setting the speed and editing the processing program on the editing page, the glass is drilled and cut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com