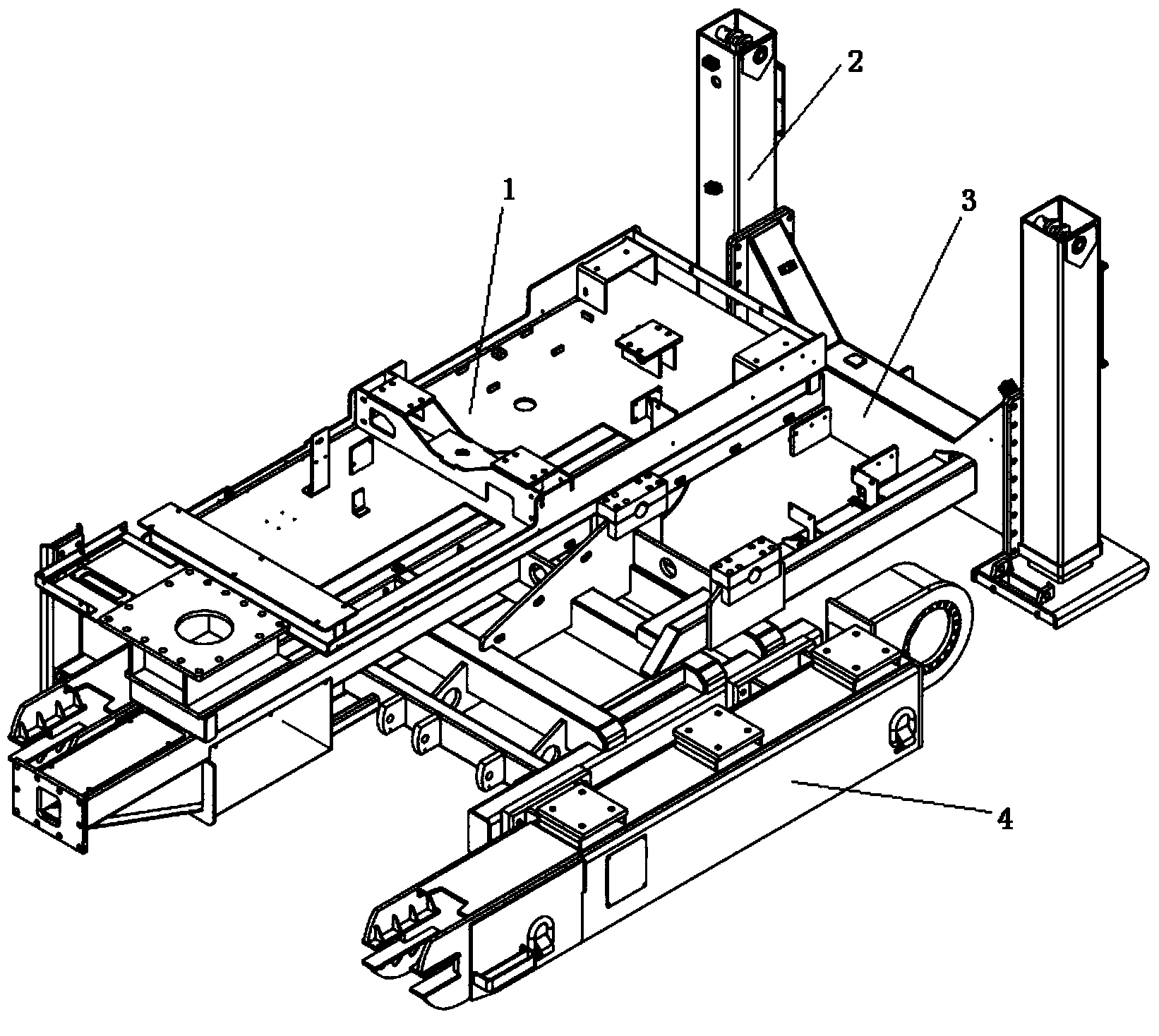

Horizontal guiding drilling machine chassis

A drilling rig and chassis technology, applied in the direction of motor vehicles, vehicle maintenance, substructure, etc., can solve the problems of poor load capacity of the whole machine, reduced frame assembly space, and inability to meet work needs, etc., to improve the load capacity and increase the bearing load. , light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be noted that the embodiments are illustrative, not restrictive, and cannot limit the protection scope of the present invention.

[0014] A horizontally oriented drilling rig chassis includes a vehicle frame 3, left and right crawler beams 4, an engine frame 1, and left and right outriggers 2. The vehicle frame is a frame structure welded by rectangular tubes, and the rectangular tubes are Q345B manganese steel rectangular tubes. The left and right track beams are installed on the left and right sides of the frame. The left and right track beams are track beams made of Q345B manganese steel plates. The track beams and the frame are connected by bolts and positioned by positioning pins. The track beams and the frame are detachable. connection structure. The engine frame is welded and installed on the upper end of the vehicle frame. The left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com