Circuit board and manufacture method thereof

A production method and circuit board technology, which are applied in the directions of printed circuit manufacturing, printed circuit, and chemical/electrolytic method to remove conductive materials, etc., can solve the problem of difficult control of drilling and electroplating precision, high production cost of circuit boards, and failure of circuit boards. The problem of high rate, to avoid reliability risks and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The manufacturing method of the double-sided circuit board provided by the technical solution will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] The manufacturing method of the double-sided circuit board provided by this technical solution comprises steps:

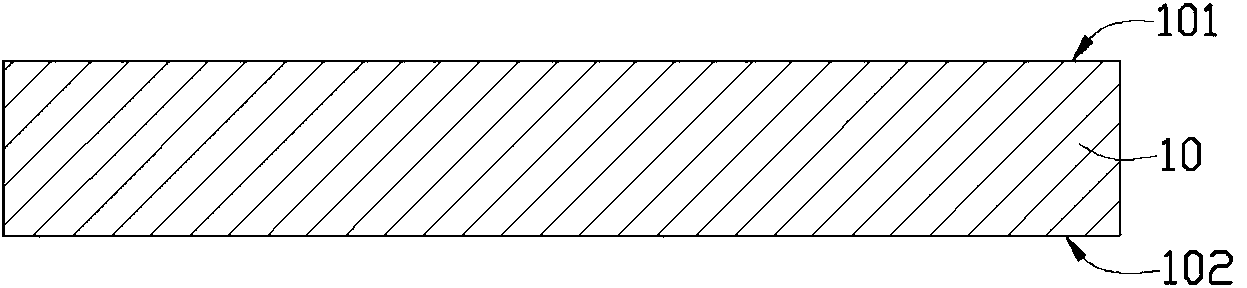

[0026] first step, such as figure 1 As shown, a first copper foil 10 having opposing first and second surfaces 101 and 102 is provided. The first copper foil 10 may be a rolled copper foil, and its thickness may be 12 microns to 120 microns.

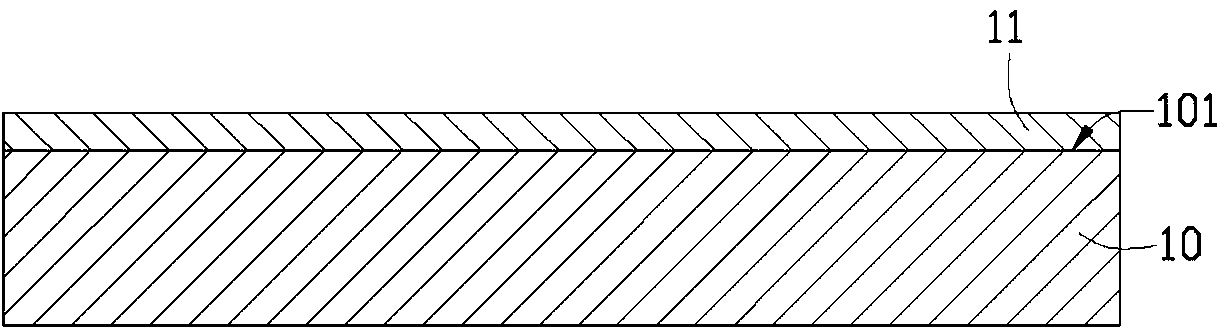

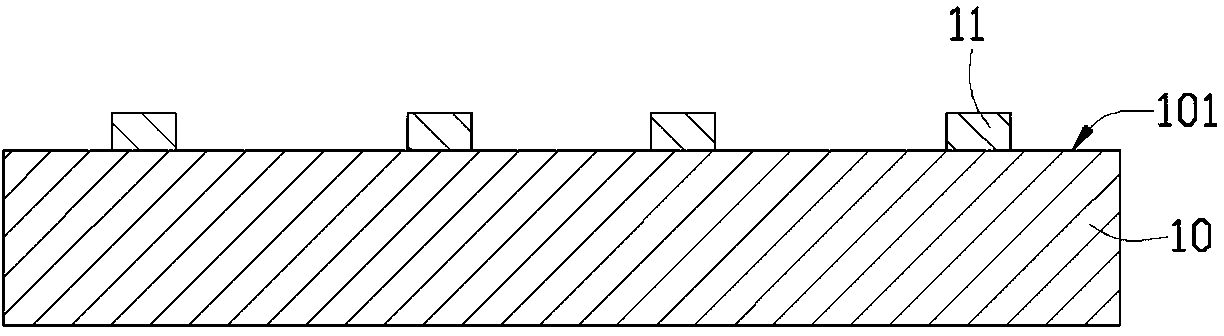

[0027] In the second step, please also refer to the Figure 2 to Figure 5 , etching the first copper foil 10 from the first surface 101 to remove a part of the first copper foil 10 close to the first surface 101 so as to form the first copper foil 10 into an intermediate structure 12 . The intermediate structure 12 includes a base 120 close to the second surface 102 and a plurality of first protrusions 121 exten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com