Rear wheel drive electric forklift provided with wet-type braking front axles

A rear-wheel drive, electric forklift technology, applied in the transmission system field, can solve the problems of reducing the battery installation space and the driver's leg space, restricting the performance of the battery counterbalanced forklift truck, and the large size of the brake, so as to optimize the manpower. Mechanical engineering design, compact structure and small braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

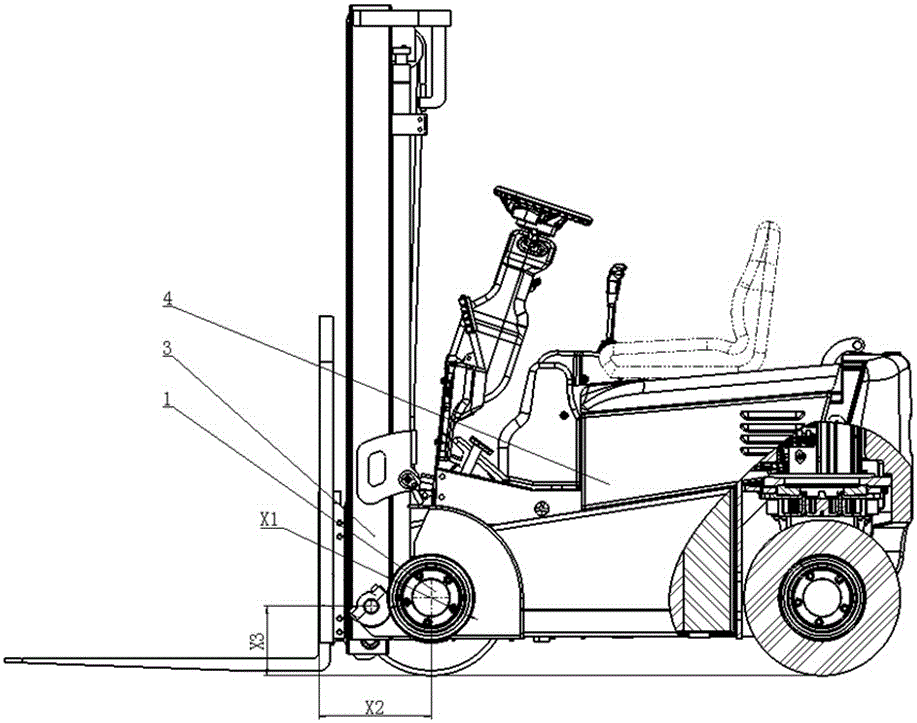

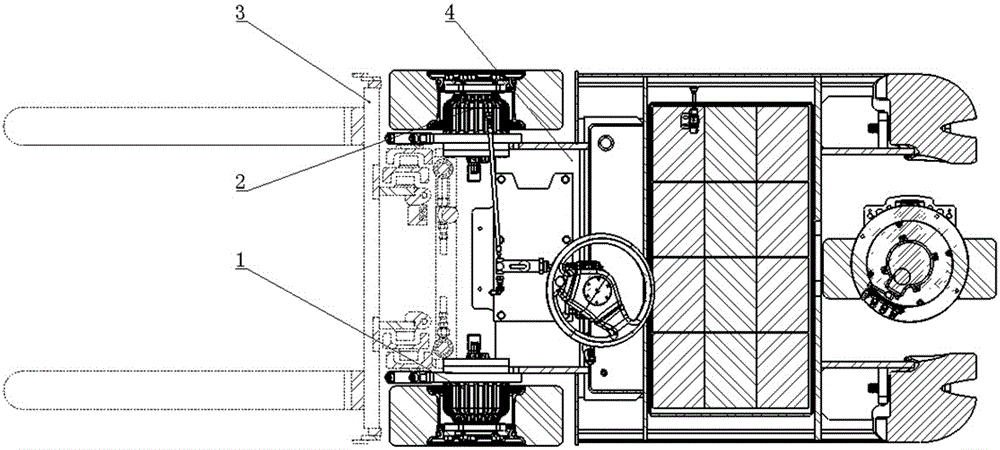

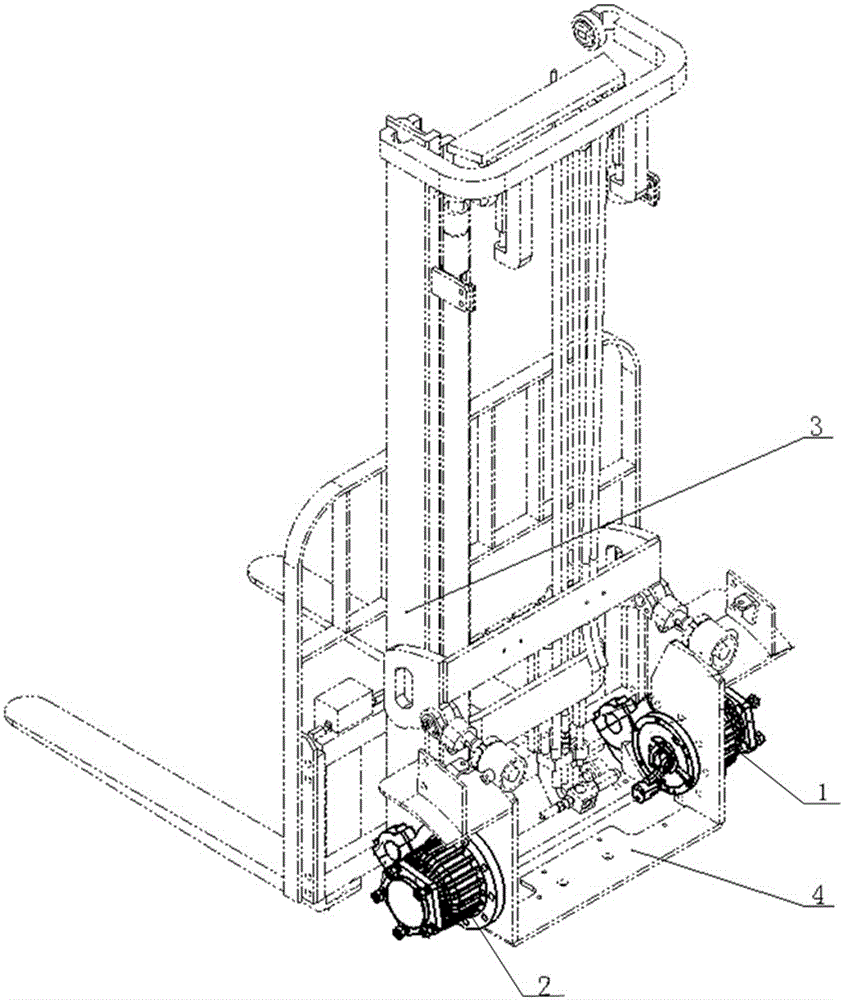

[0036] see figure 1 and figure 2 , The rear-wheel drive electric forklift with wet brake front axle includes a front axle mechanism, a lifting system and a body system; the body system includes a frame, a driving rear axle and a travel steering mechanism. see image 3 and Figure 4 , The front axle mechanism is a split type, consisting of a left front axle and a right front axle; the left front axle and the right front axle have the same structure, opposite directions, symmetrical positions, and are respectively arranged on the left and right sides of the front of the frame.

[0037] see Figure 5 , the left front axle or the right front axle includes a tubular casing 11, a planetary gear output mechanism, a wet braking mechanism and a left or right front wheel. Both the planetary gear output mechanism and the wet braking mechanism are located in the casing 11 , and a casing cover 111 is provided at one end of the casing 11 in the axial direction.

[0038] The planetary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com