Transmission gap adjusting mechanism of gantry numerical control cutting machine

A cutting machine and clearance adjustment technology, used in welding/cutting auxiliary equipment, mechanical equipment, portable lifting devices, etc., can solve problems such as poor gear and rack meshing, increase manufacturing costs, and difficulty in limit errors, and achieve large assembly space. , The effect of reducing manufacturing cost and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below the present invention will be further described in conjunction with the embodiment of accompanying drawing:

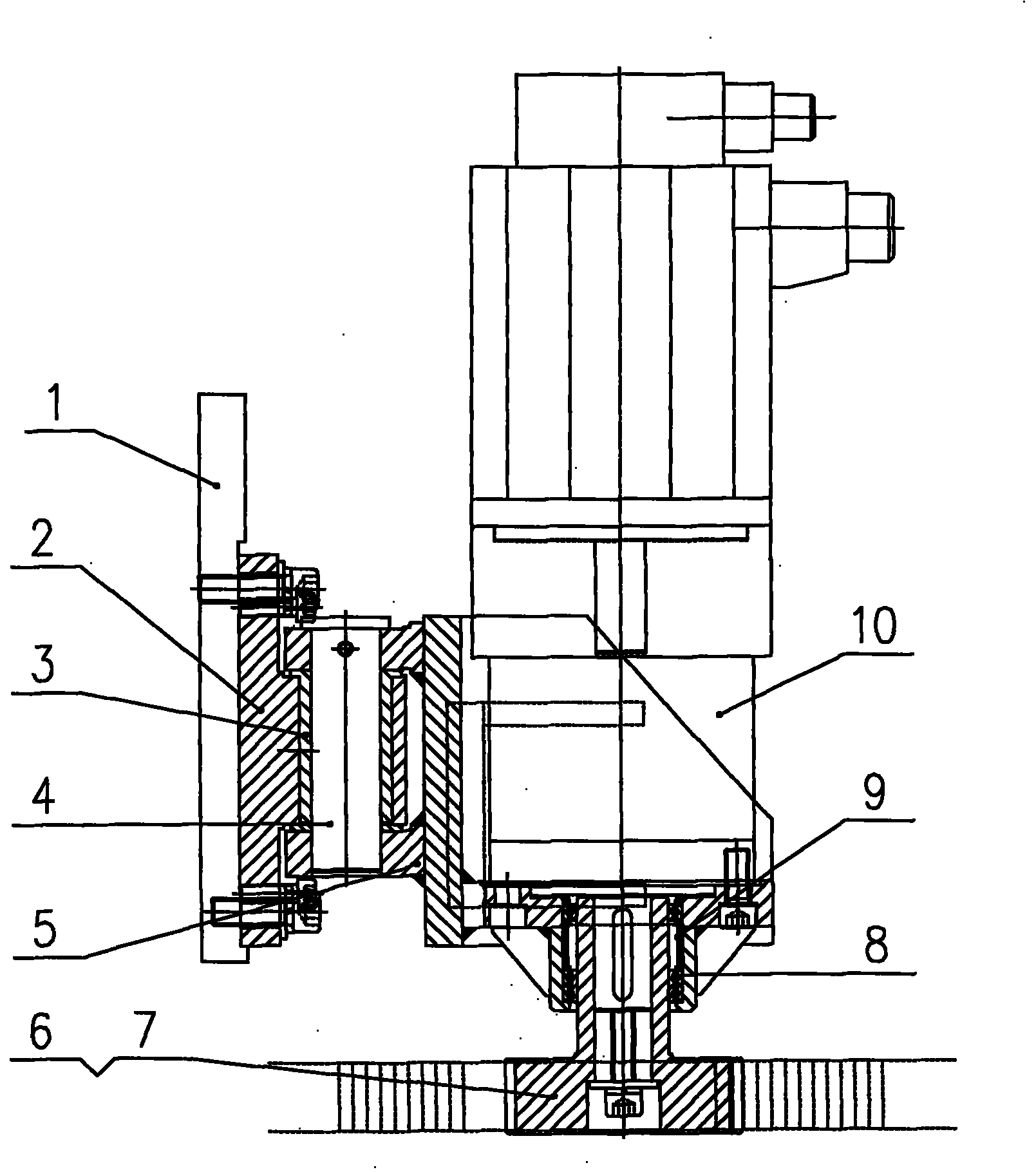

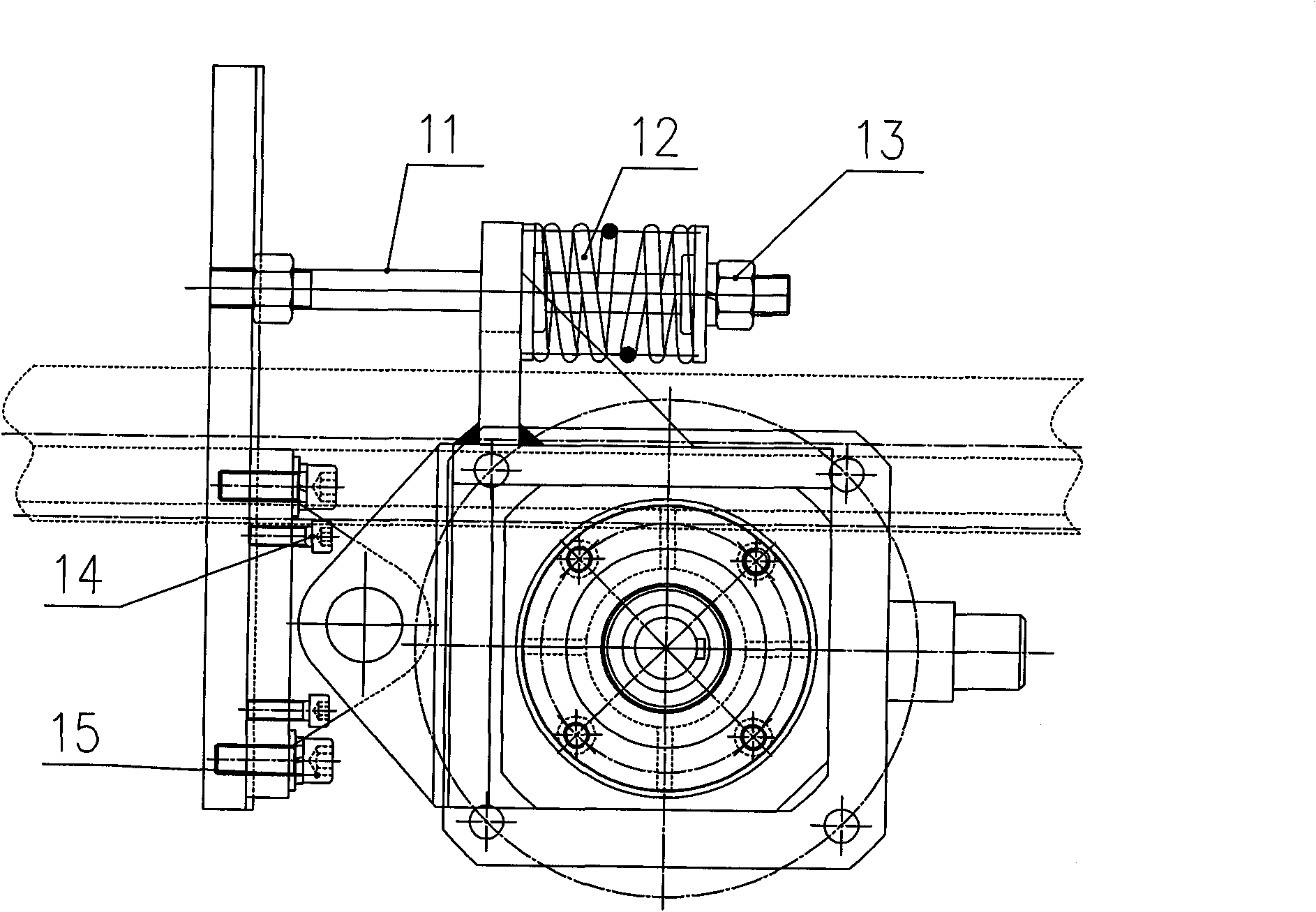

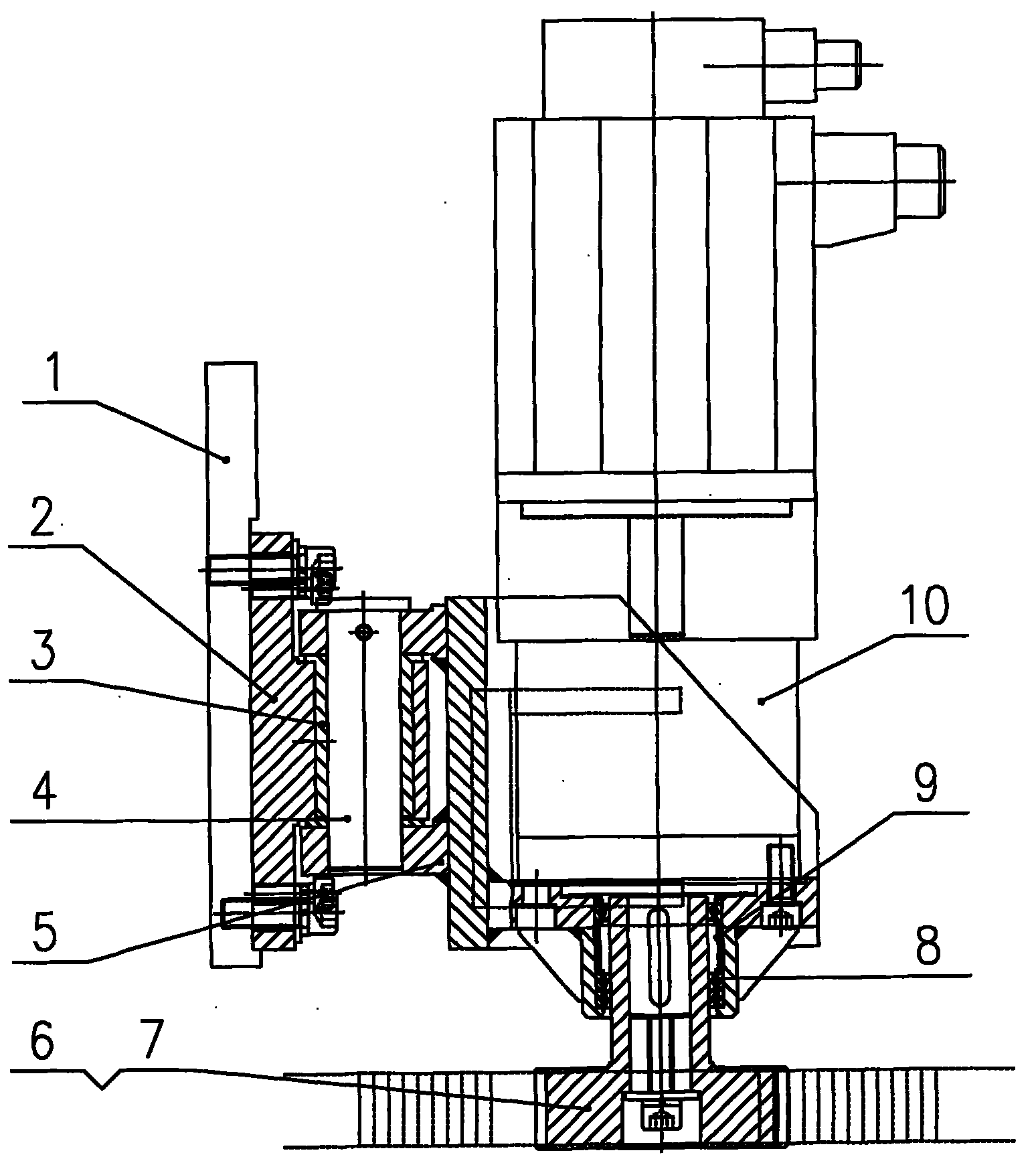

[0011] The gap adjustment mechanism of the CNC cutting machine of the present invention is mainly composed of a frame 1, a fixed seat 2, a copper sleeve 3, a rotating shaft 4, a mounting seat 5, a gear 6, a rack 7, a bearing 8, a spacer 9, a reducer 10, and a screw 11. Spring 12, nut 13, first bolt 14, second bolt 15 and so on.

[0012] The transmission gap adjustment mechanism of the CNC cutting machine of the present invention mainly adopts the fixed seat 2 to be installed on the frame 1 by the second bolt 15, and the left and right vertical can be adjusted by the first bolt 14, and the mounting seat 5 is connected by the rotating shaft 4 and the copper sleeve 3. Rotation, the gear 6 is connected with the output shaft of the reduction box 10, the outer ring of the gear 6 is equipped with a bearing 8 to play a protective role, the spacer 9 presses the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com