Rice cleaning device

A cleaning device and rice technology, which are applied in the directions of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems that affect the cleaning quality of rice and are not easy to discharge, and achieve the effect of simplifying the structure and not easy to slip.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Further detailed explanation through specific implementation mode below:

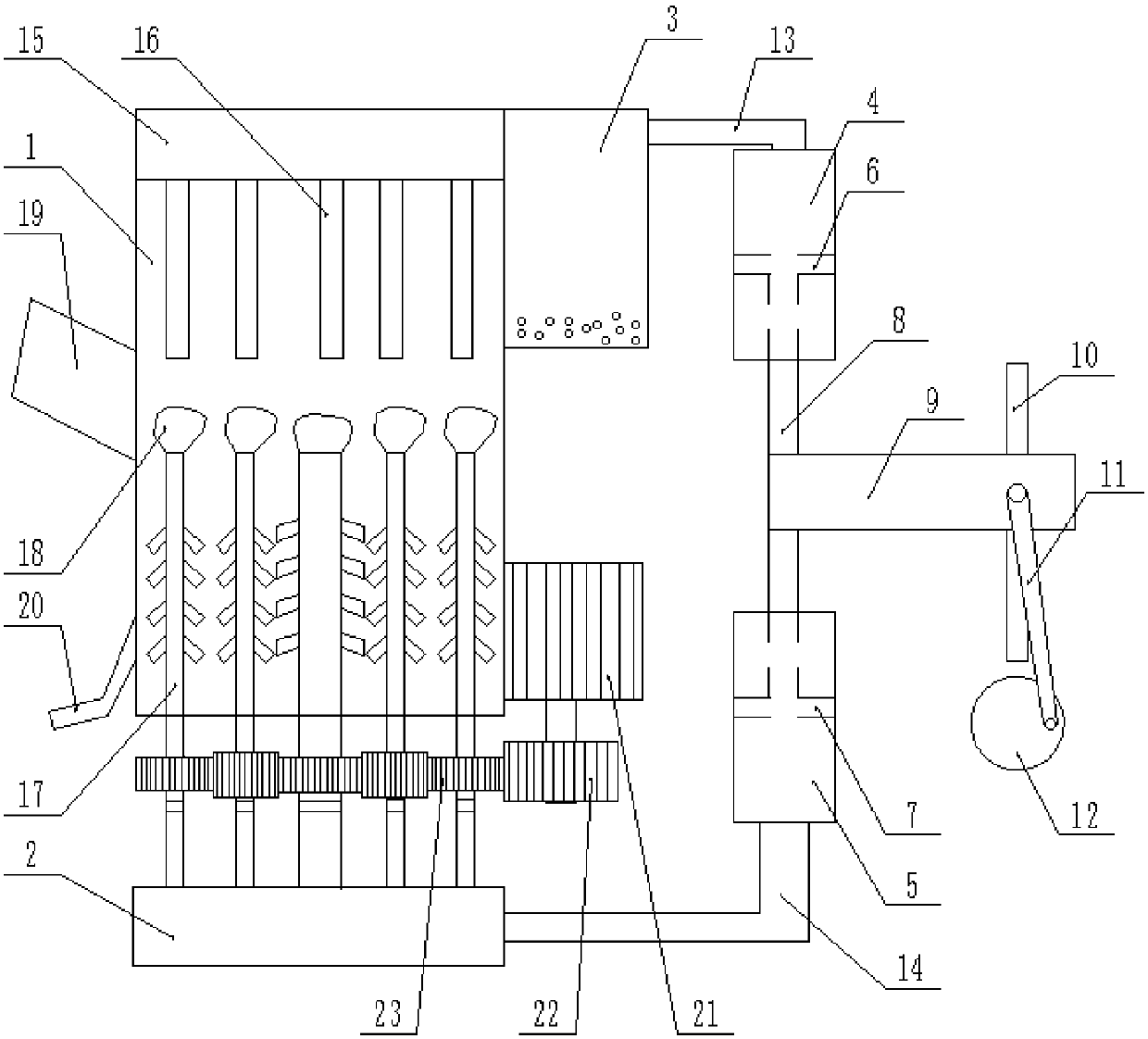

[0014] The reference signs in the accompanying drawings of the specification include: cleaning chamber 1, gas tank 2, miscellaneous storage chamber 3, upper piston chamber 4, lower piston chamber 5, upper piston 6, lower piston 7, piston rod 8, slider 9, guide rail 10. Connecting rod 11, turntable 12, first through pipe 13, second through pipe 14, suction cavity 15, suction pipe 16, stirring tube 17, balloon 18, feed port 19, water outlet 20, first motor 21, the second spur gear 22, the first spur gear 23.

[0015] The embodiment is basically as attached figure 1 Shown: a kind of rice cleaning device, comprises cleaning room 1, and the top of cleaning room 1 is provided with suction chamber 15, and the bottom of cleaning room 1 is provided with air tank 2, and the right side of cleaning room 1 is provided with upper piston cavity 4 and The lower piston cavity 5 and the cleaning chamber 1 are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com