Heat exchange pipe and pipe plate welding method and application thereof

A technology for tube-sheet welding and heat exchange tubes, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of poor fusion of the joint root and the joint structure hindering fluid flow, etc., to strengthen the bonding force and prevent the root gap. Corrosion and the effect of avoiding residual fluid accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

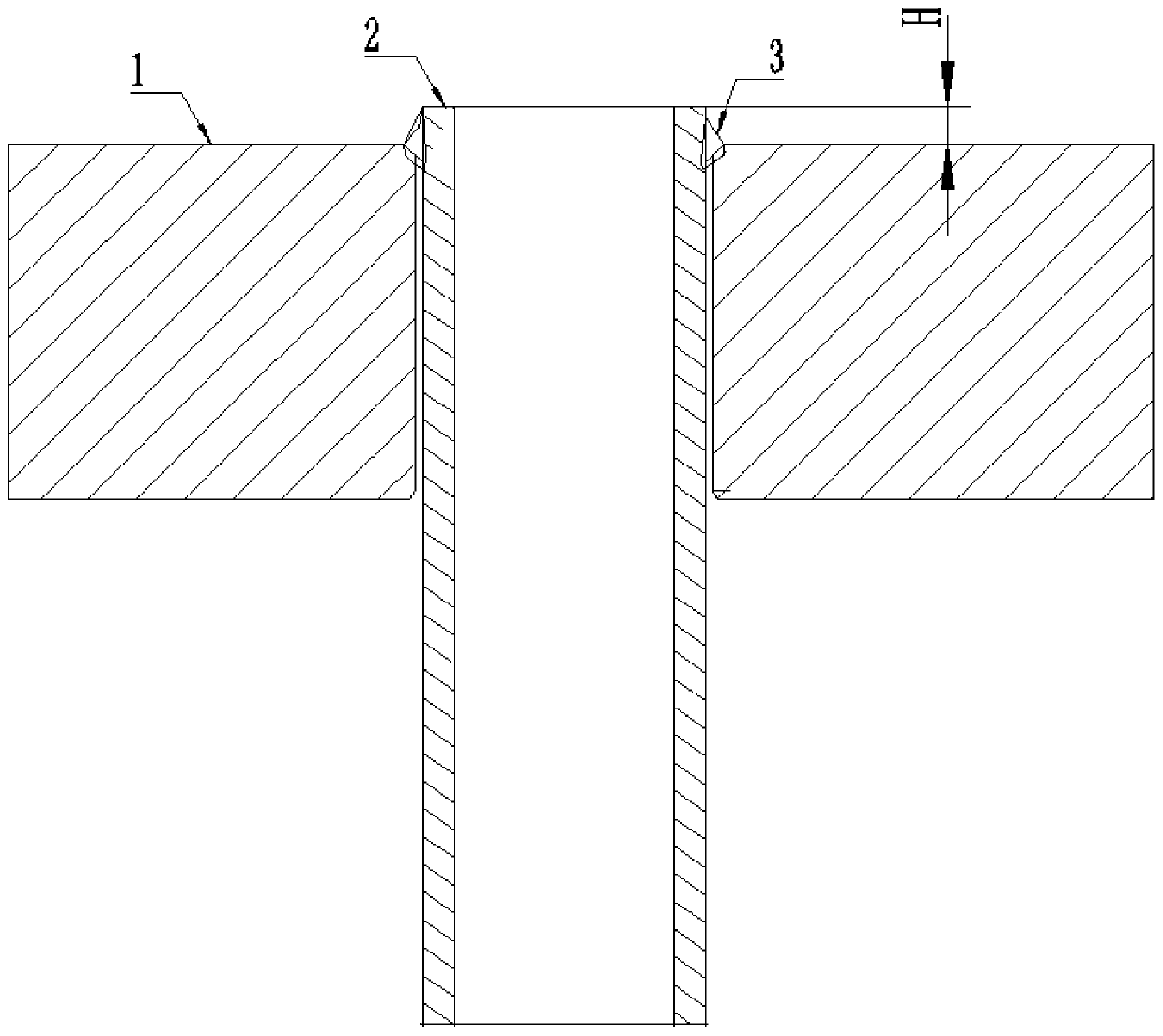

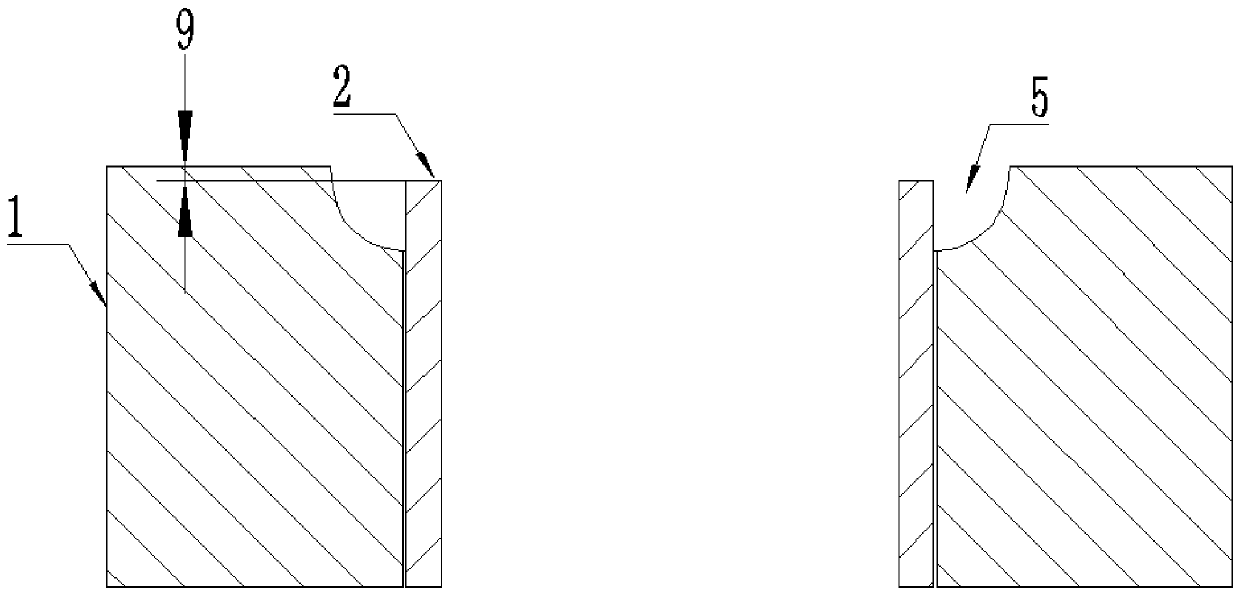

[0035] First embodiment , Exemplify a process of welding heat exchange tubes and tube sheets using the method of the present invention, the thickness of the tube sheet 2 is 30mm, and the specifications of the heat exchange tube 2 are made of Φ38×3.5 heat exchangers, and the polishing accuracy requires Ra0.1. Including the following steps:

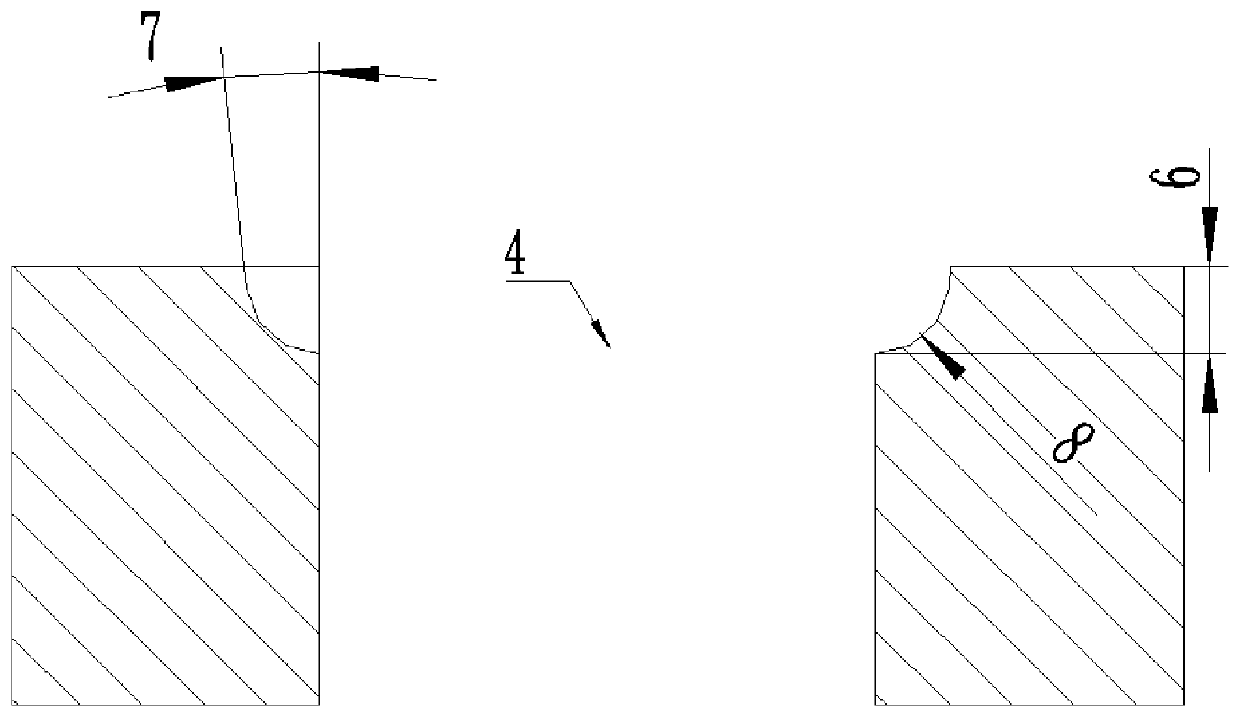

[0036] (1) Groove processing: reference figure 2 , Use a milling machine to process all pipe holes 4 as required, the pipe hole diameter is φ32.35 0 +0.2 , The groove depth 6 is 6mm, the groove angle 7 is 5mm, and the root arc radius 8 is R5; after completion, the burr of the tube plate hole is cleaned with a wire wheel and an internal grinder and the groove surface is smoothed. Dedicated pipe hole processing size inspection template, timely rectification if the size is unqualified, to ensure that the pipe hole processing size meets the requirements;

[0037] (2) Cleaning the tube plate hole: Use cotton yarn to remove the oil and water stains ...

no. 2 example

[0044] Second embodiment , Exemplify another process of welding heat exchange tubes and tube sheets using the method of the present invention, which specifically includes the following steps:

[0045] (1) Groove processing: use a milling machine to process all pipe holes 4 as required, the pipe hole diameter is φ 32.35 0 +0.2 , The groove depth 6 is 10mm, the groove angle 7 is 6mm, and the root arc radius 8 is R4; after completion, the burr of the tube plate hole is cleaned with a wire wheel and an internal grinder and the groove surface is smoothed. Dedicated pipe hole processing size inspection template, timely rectification if the size is unqualified, to ensure that the pipe hole processing size meets the requirements;

[0046] (2) Cleaning the tube plate hole: Use cotton yarn to remove the oil and water stains on the tube hole groove and the surface of the tube plate. If necessary, use alcohol to clean it.

[0047] (3) Heat exchange tube pairing: Insert heat exchange tube 2 into...

no. 3 example

[0052] The third embodiment , Illustrate another process of welding the heat exchange tube and the tube sheet using the method of the present invention, the same as the second embodiment, the difference is: (1) Groove processing: groove depth 6 is 8mm, groove angle 7 is 4mm, The root arc radius 8 is R6; after completion, use a wire wheel and an internal grinder to clean the burrs of the tube sheet hole and smooth the groove surface. According to the special tube hole processing size inspection template, timely correction of the unqualified size , To ensure that the pipe hole processing size meets the requirements;

[0053] (3) Heat exchange tube pair: the height of the end of the heat exchange tube to be welded below the end surface of the tube plate is 3.0mm.

[0054] After polishing, the nuclear industry-grade penetrant is used for 100% penetrant testing, which meets the requirements of NB / T47013-2015 and is qualified as Class I.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com