Patents

Literature

70results about How to "Reduce effusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

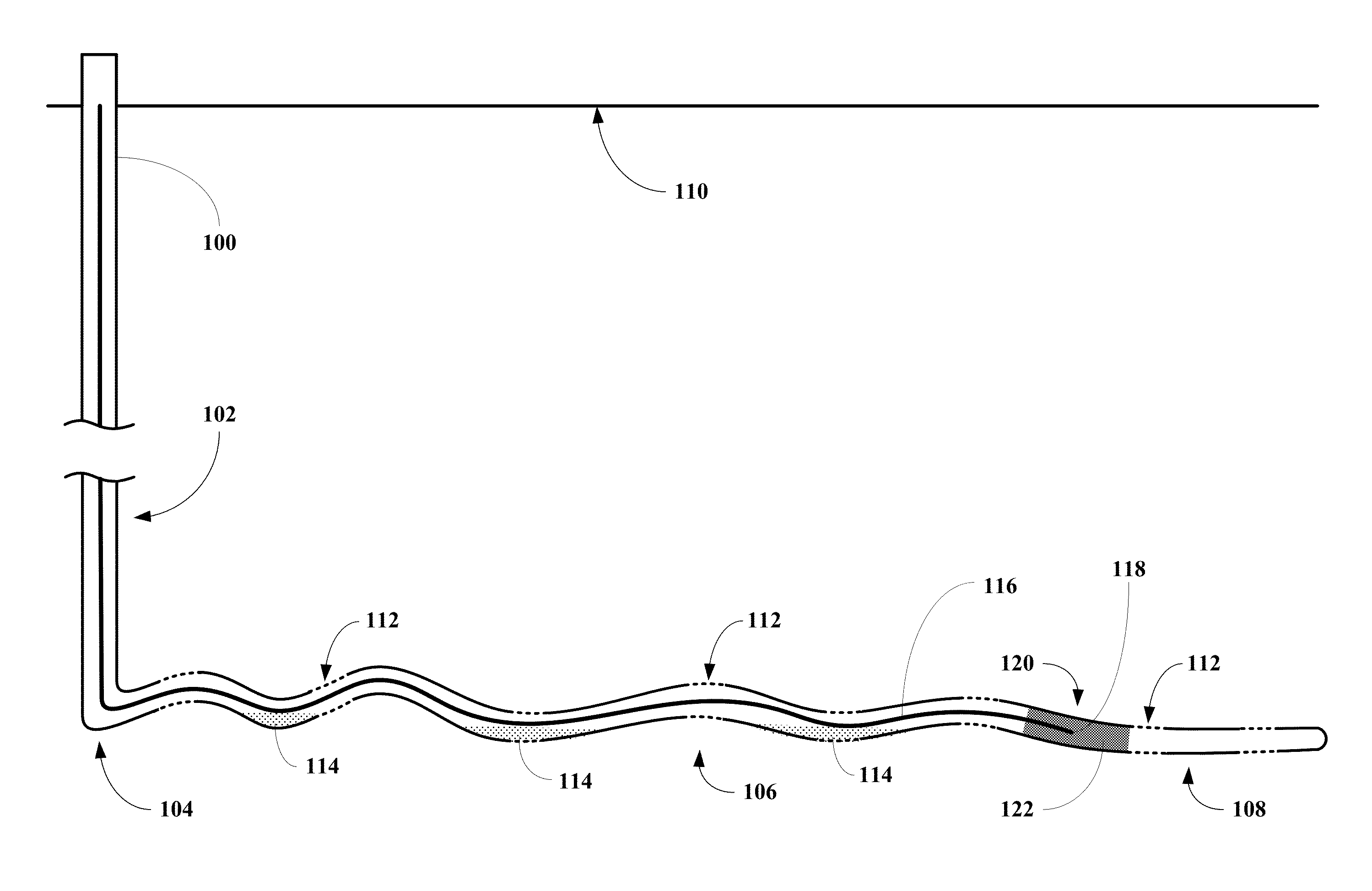

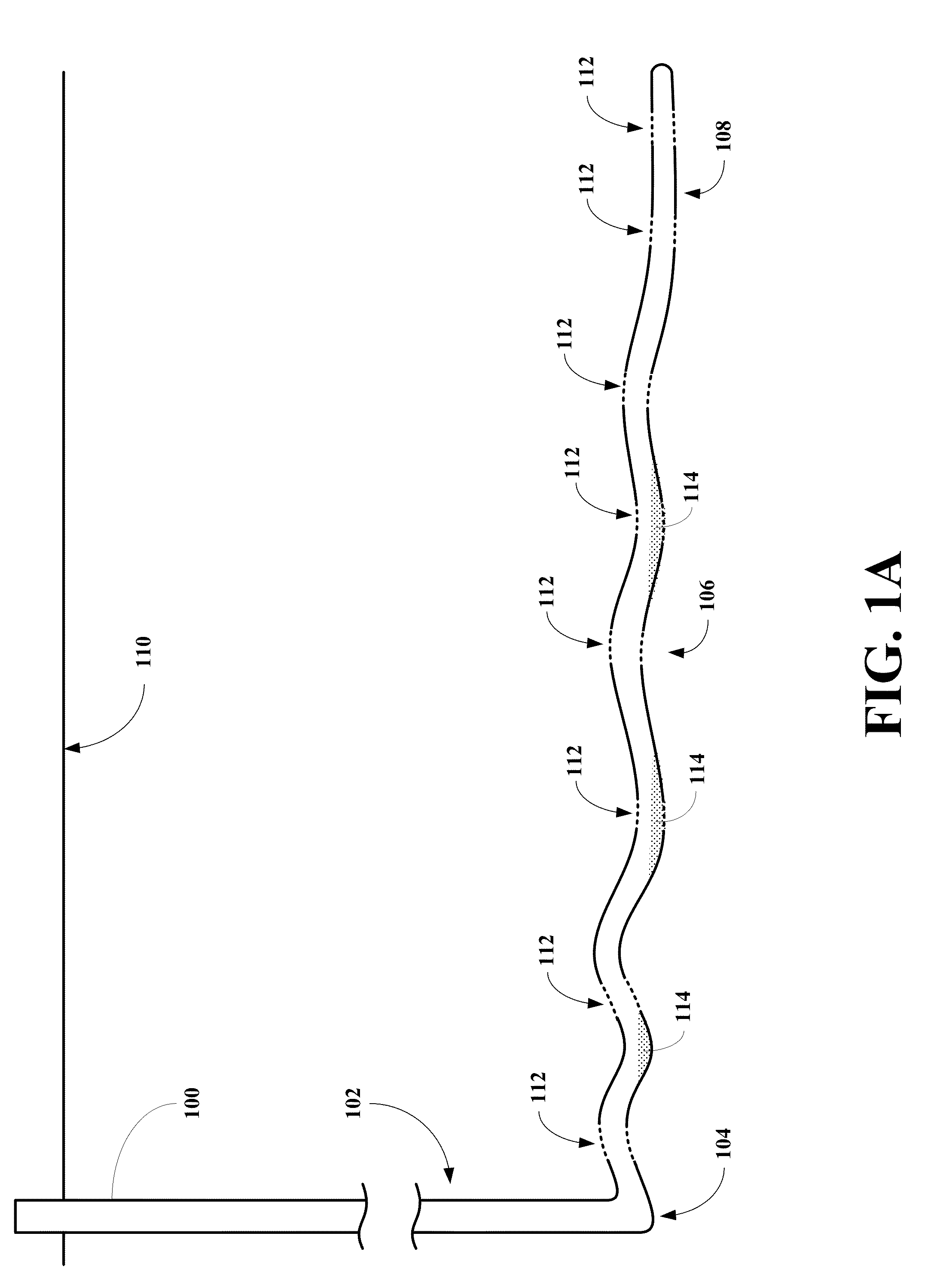

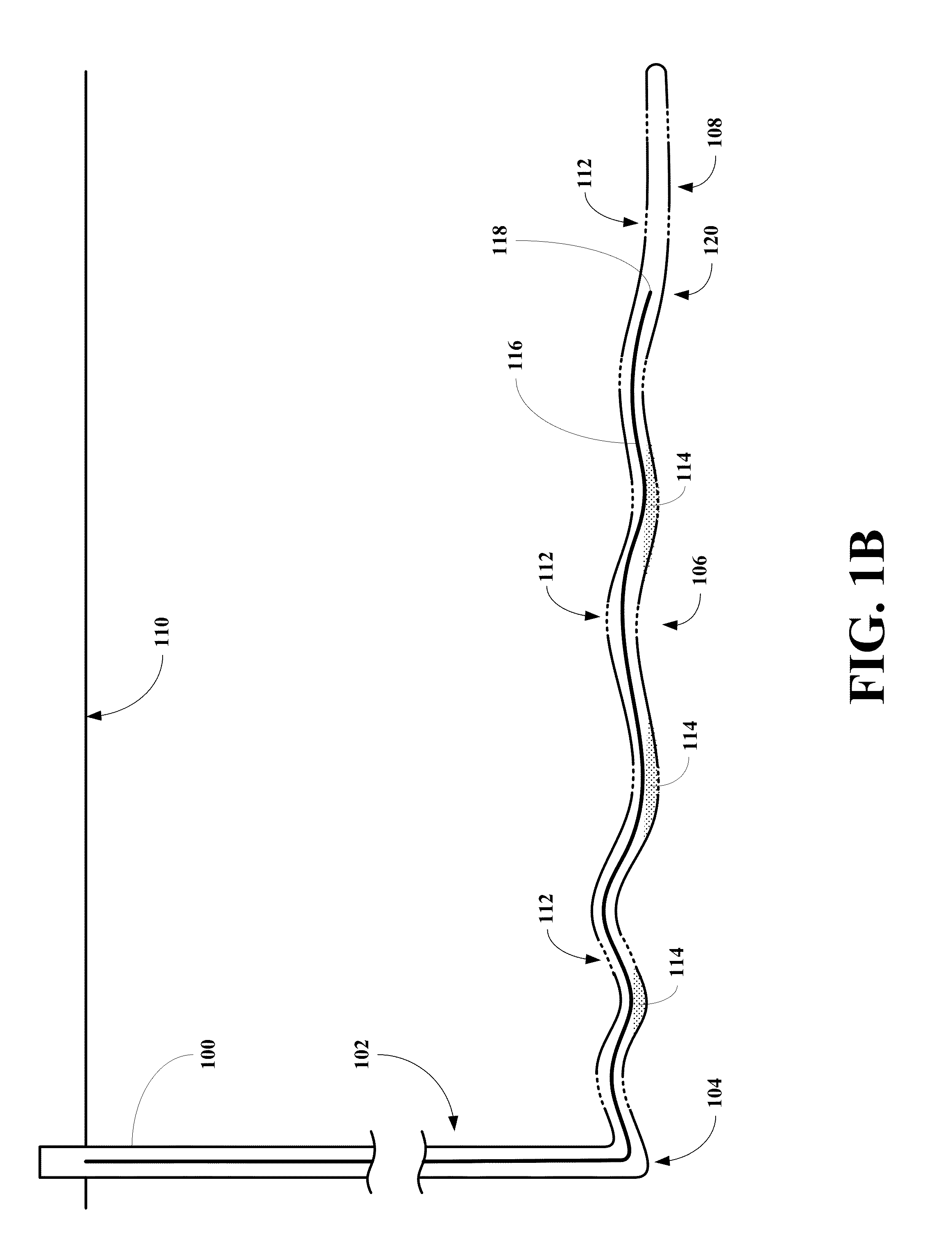

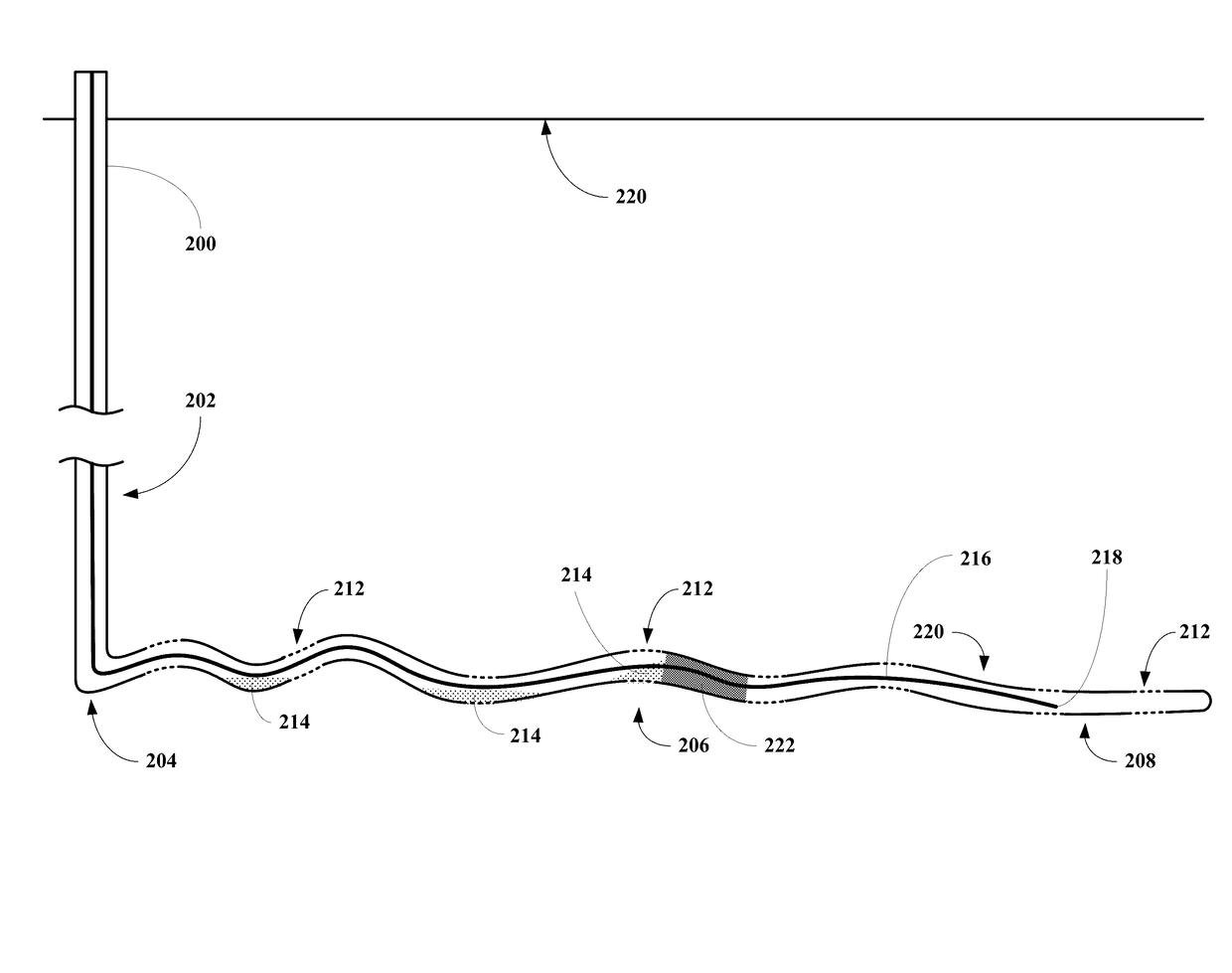

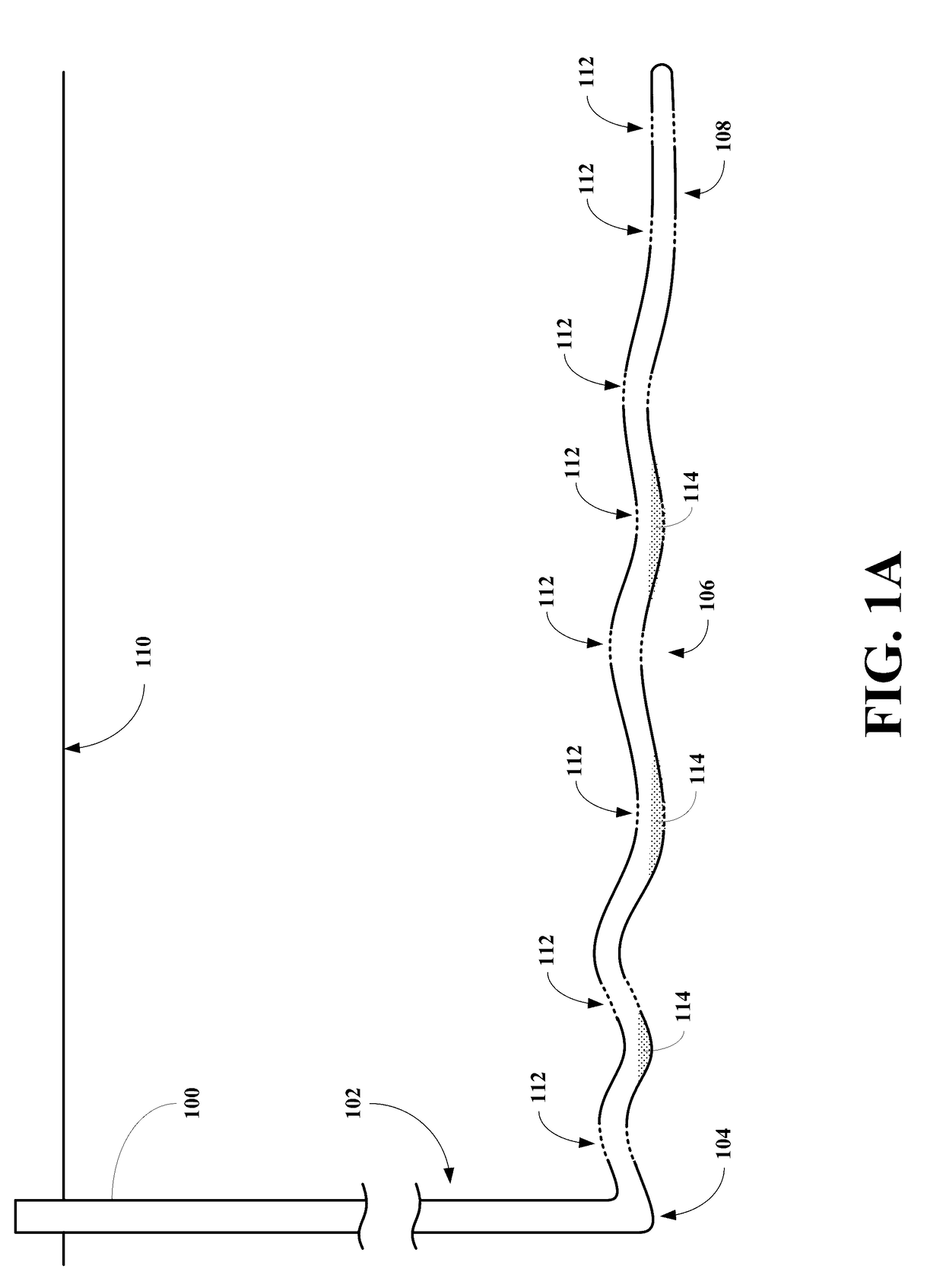

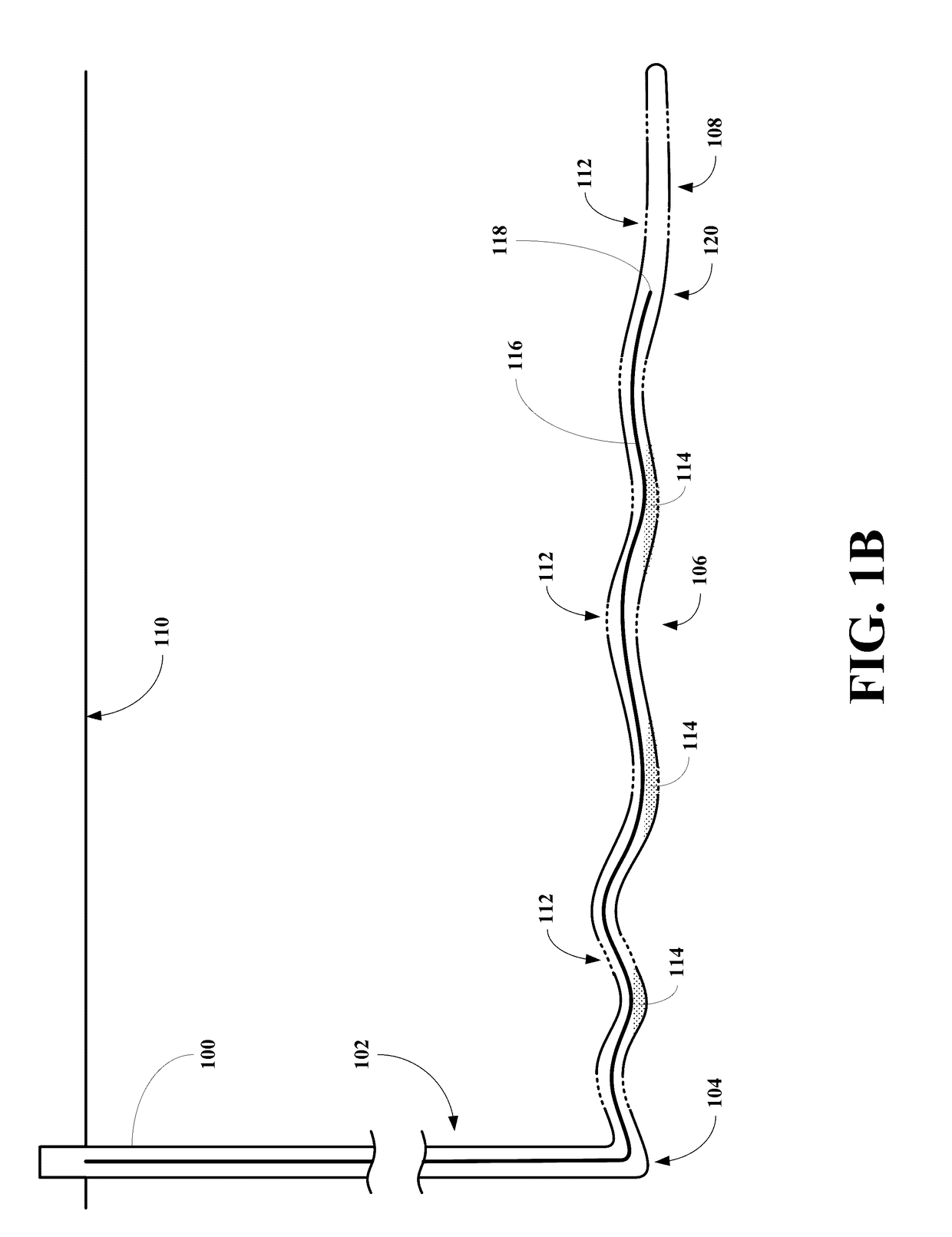

Apparatuses, systems, and methods for forming in-situ gel pills to lift liquids from horizontal wells

InactiveUS20130312977A1Low viscosityIncrease gas productionDrilling rodsCleaning apparatusHorizontal wellsEngineering

Methods include the injection of a gelled, gelling or gellable composition into a horizontal section of a well at a location, where produced well gases or a combination of well gases and injected gases are sufficient to move the pill through the horizontal section into heal section, sweeping the horizontal section of accumulated liquids. Once in the heal section, the pill and the accumulated liquids are uplifted to the surface resulting in a cleaned well.

Owner:CLEARWATER INT LLC

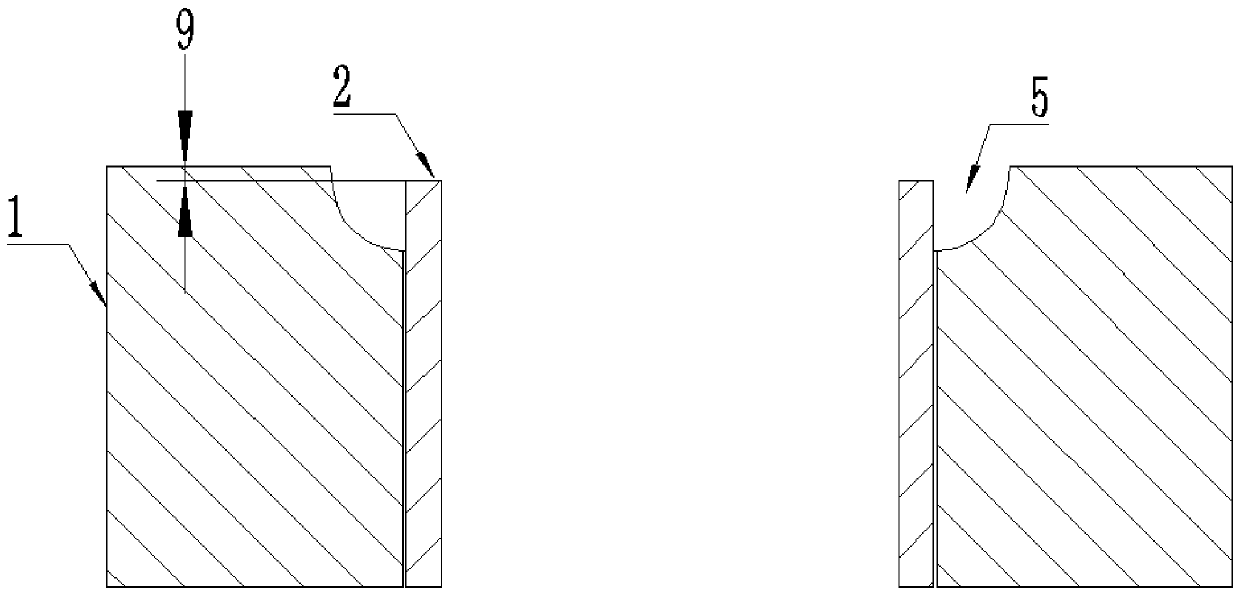

Biocompatibility of biomedical energization elements

InactiveUS20160056417A1Good biocompatibilityReduce effusionBatteries circuit arrangementsCell temperature controlBiocompatibilityBiomedical engineering

Designs, strategies and methods to improve biocompatibility of energization elements are described. In some examples, the biocompatible energization elements may be used in a biomedical device. In some further examples, the biocompatible energization elements may be used in a contact lens.

Owner:JOHNSON & JOHNSON VISION CARE INC

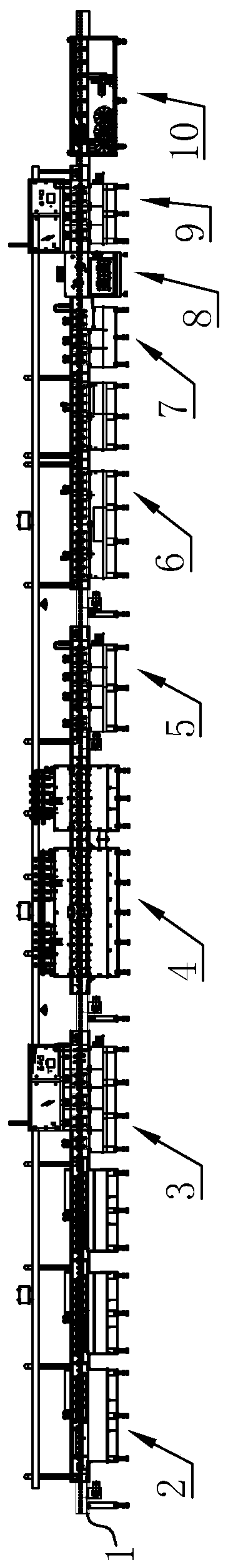

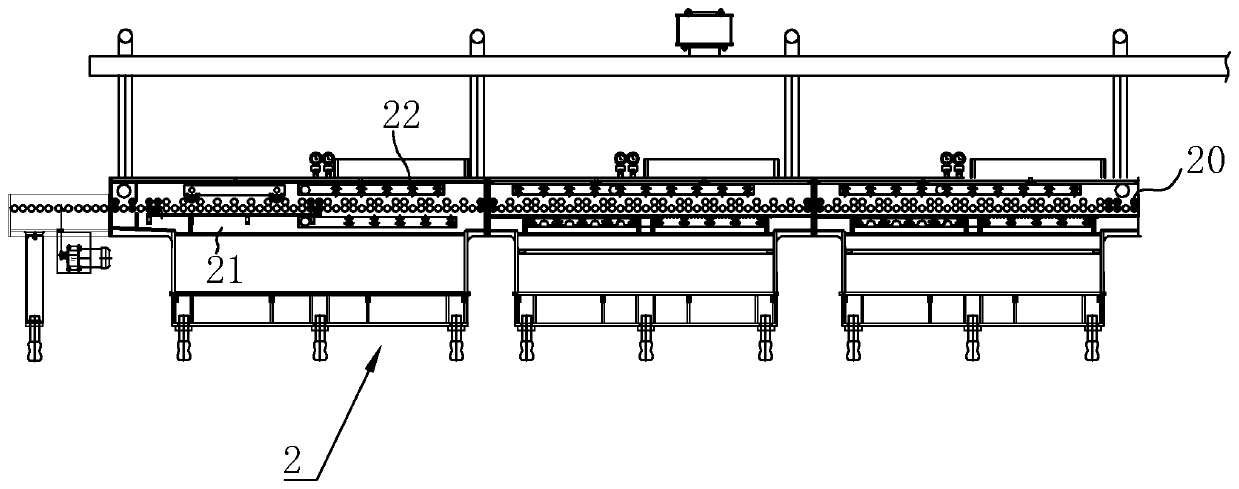

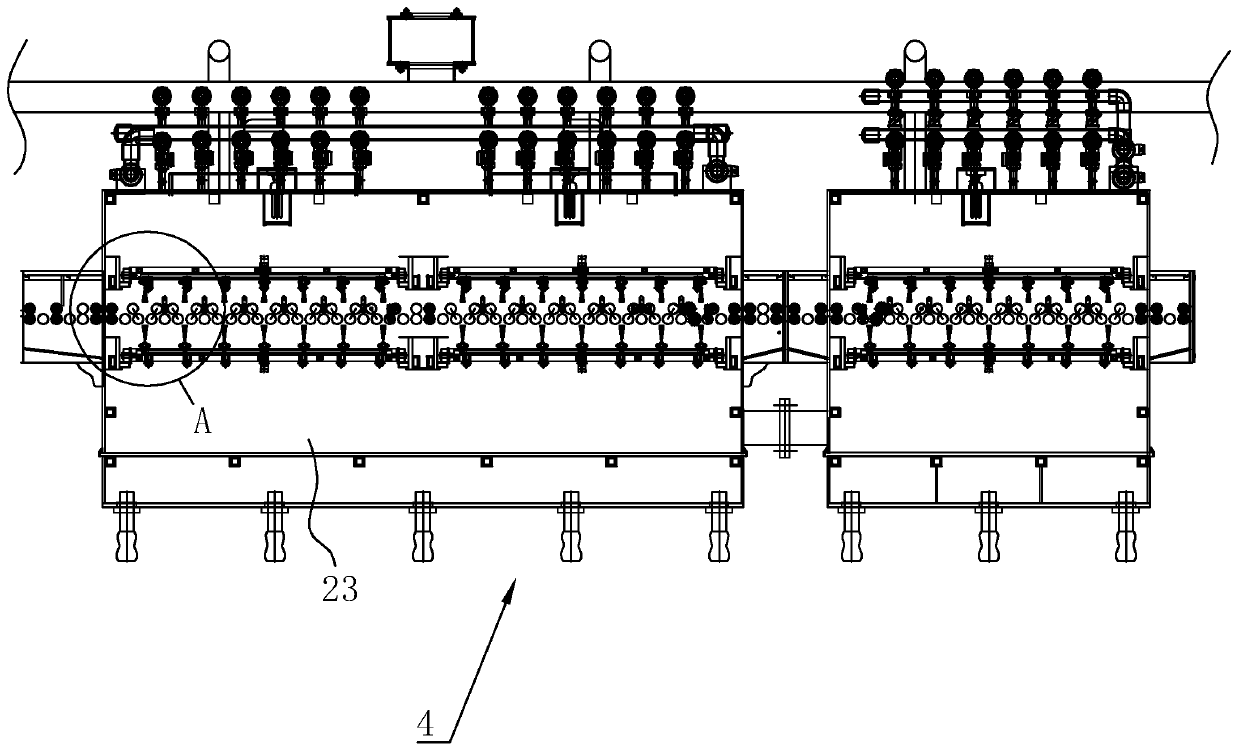

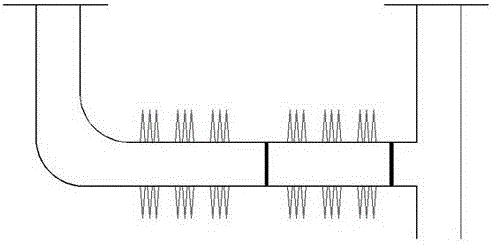

SES production line

ActiveCN110035620AAchieve recyclingGuaranteed cleanlinessConductive material chemical/electrolytical removalProduction lineEtching

The invention discloses an SES production line. The SES production line comprises a conveying table, a demoulding device, an etching device and a solder stripping device, wherein the demoulding device, the etching device and the solder stripping device are sequentially arranged in the conveying direction; the etching device comprises a vacuum etching chamber; first spraying heads used for sprayingan etching liquid is arranged in the vacuum etching chamber; the first spraying heads are located on the upper side and the lower side of a PCB respectively and are arranged at intervals in the conveying direction; a liquid sucking head used for sucking the etching liquid accumulated on the upper surface of the PCB is arranged between the adjacent first spraying heads in the conveying direction,so that the PCB is continuously conveyed forwrads on the conveying table, and the processing of demoulding, etching and solder stripping is gradually realized; and the etching liquid is sprayed to thesurface of the PCB from the upper side and the lower side through the first spraying heads in the etching process, and the etching liquid accumulated on the upper surface of the PCB is sucked away under the action of a suction force of the liquid suction head, so that the situation that an etching reaction is weakened due to the accumulated liquid on the upper surface of the PCB is effectively avoided, and the purpose of more uniform etching is achieved.

Owner:CIRCUIT TECH MACHINERY

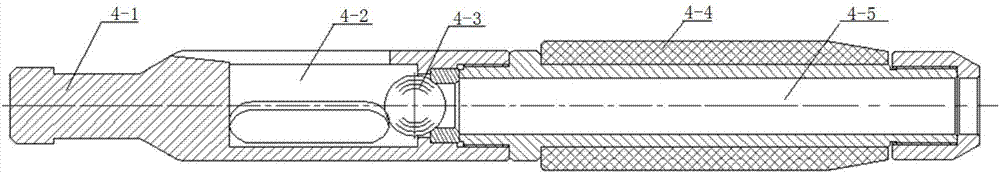

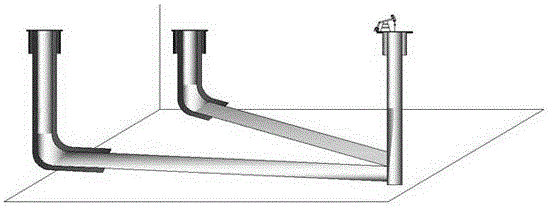

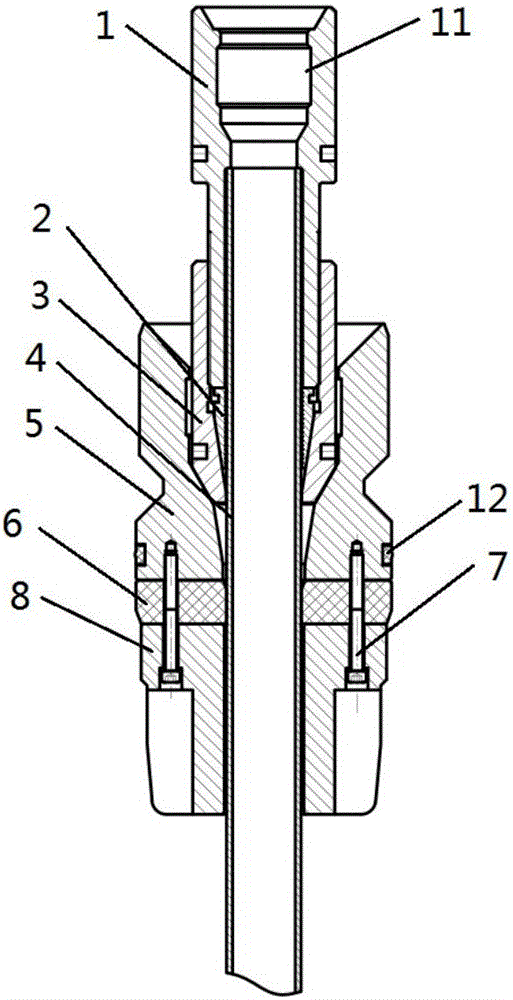

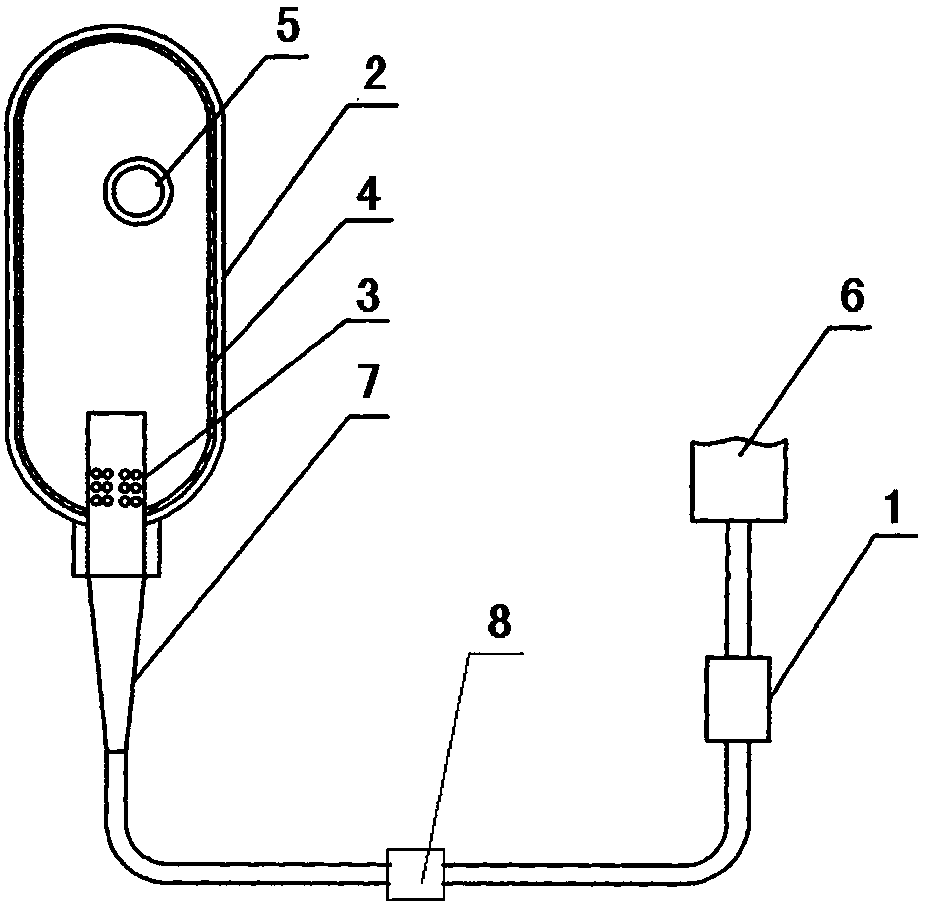

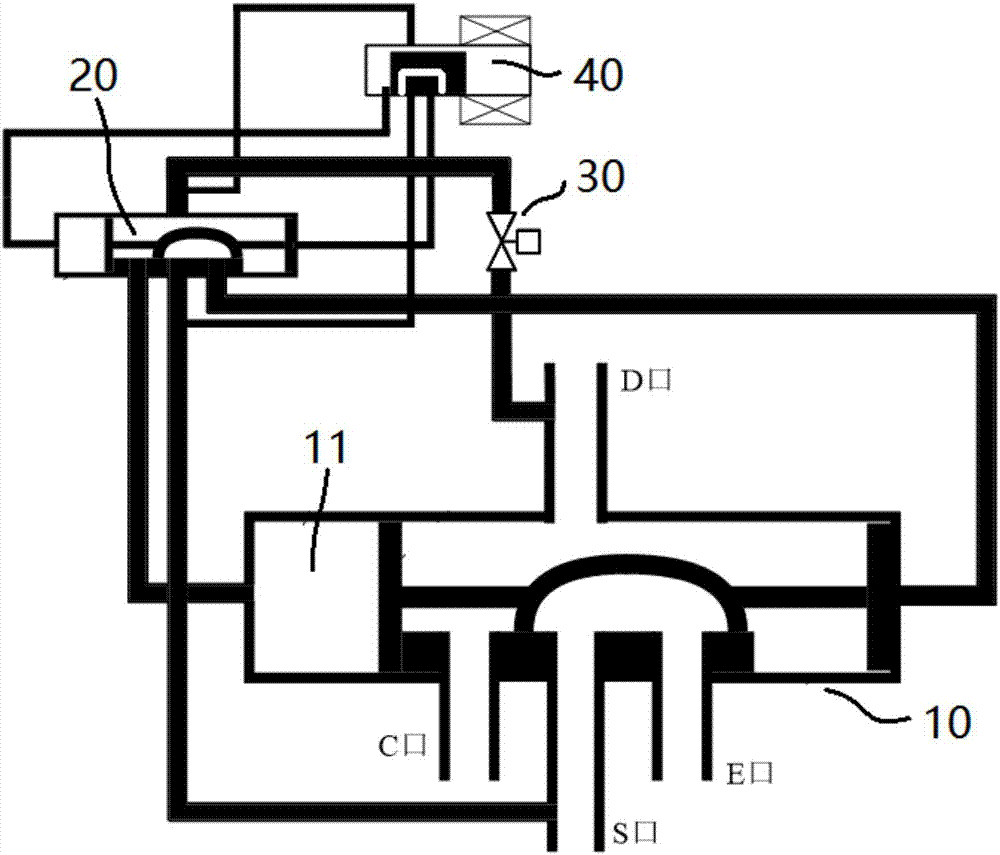

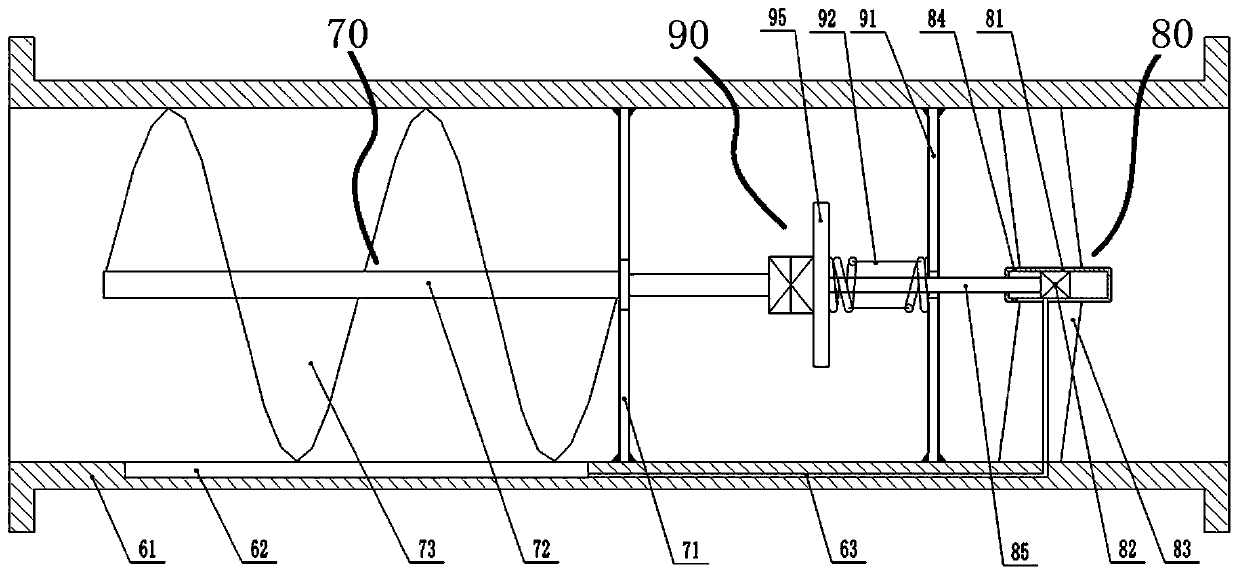

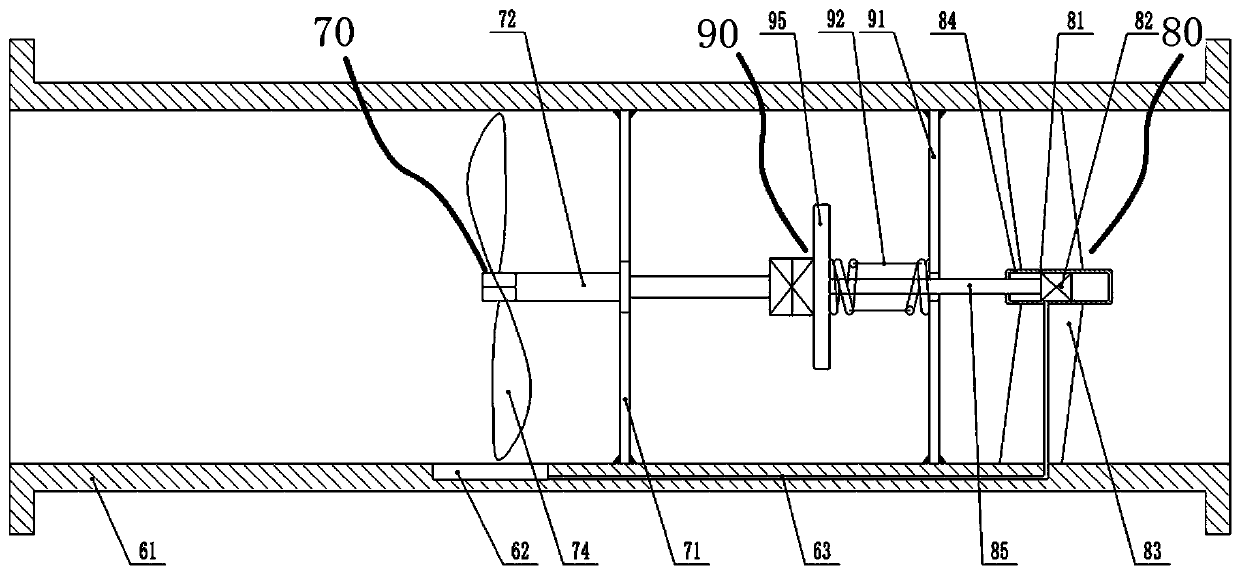

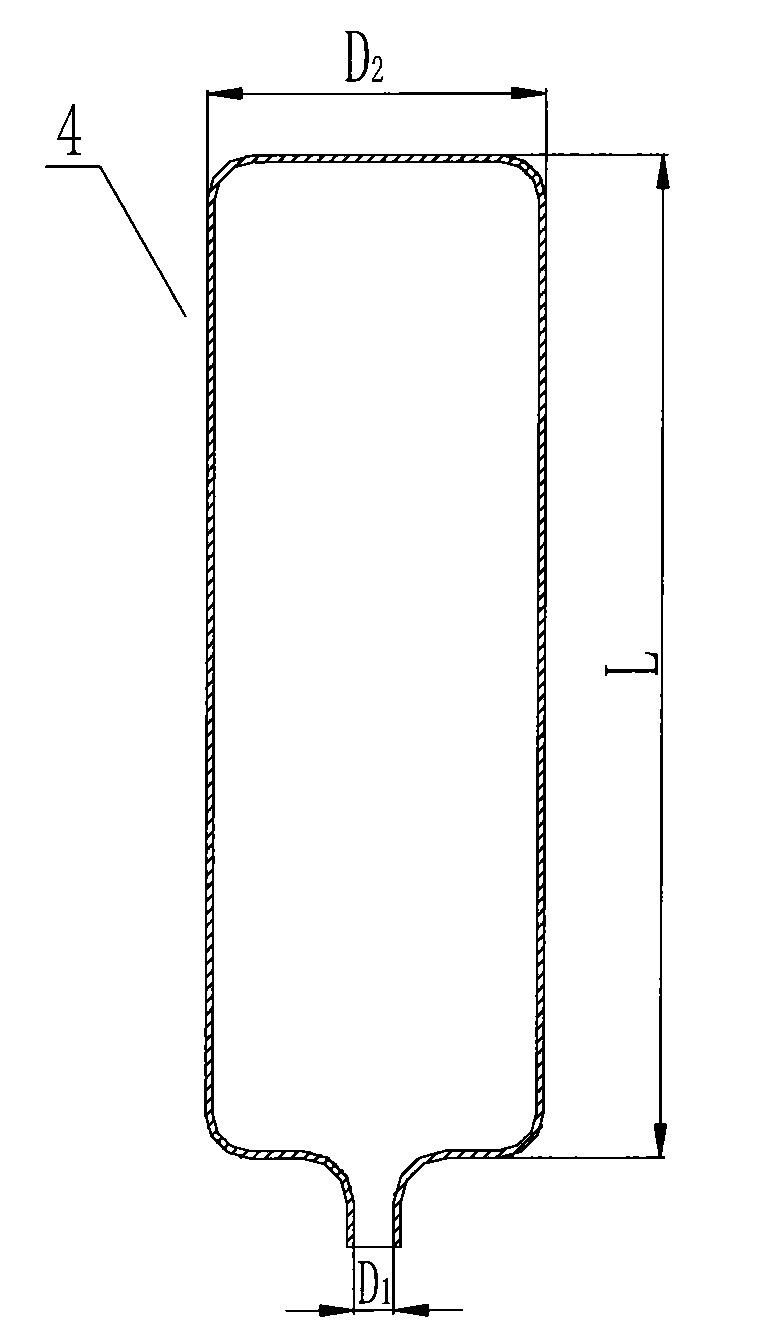

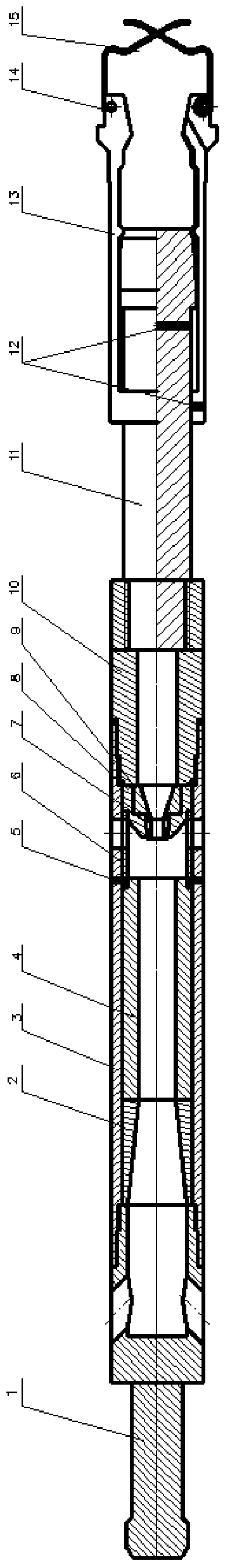

Plunger gas-lifting draining device used for horizontal gas well and production method

InactiveCN107542434AIncrease depthSimplify Downhole ToolsDrilling rodsFluid removalGas liftProcess engineering

The invention discloses a plunger gas-lifting draining device used for a horizontal gas well and a production method. The device comprises a self-buffering plunger and a uniflow device which are arranged in an oil pipe, the oil pump comprises two sections of pipelines who have different pipe diameters and are connected by a reducing short section, the self-buffering plunger is arranged in the part, which is located at the upper part of the reducing short section, of the pipeline, the uniflow device is used for controlling a gas liquid to flow unidirectionally from bottom to top and arranged inthe part, located at the lower part of the reducing short section, of the pipeline, the shaft accumulated fluid can be lifted to the upper part of the uniflow device by the own energy of the gas well, is delayed, and is lifted to the well mouth by the aid of the self-buffering plunger, and drainage production is completed. A downhole tool of an existing plunger device is simplified; the functionof gas liquid unidirectional flow is realized by the uniflow device, the structure is simple and easy to put and slave, the own lifting capacity of the gas well is effectively utilized, the shaft accumulated fluids of the horizontal gas well bottom part inclined shaft part and horizontal section are lifted, the shaft liquid column height is reduced greatly, the gas yield is increased, and the horizontal gas well draining gas production difficulty is effectively solved.

Owner:PETROCHINA CO LTD

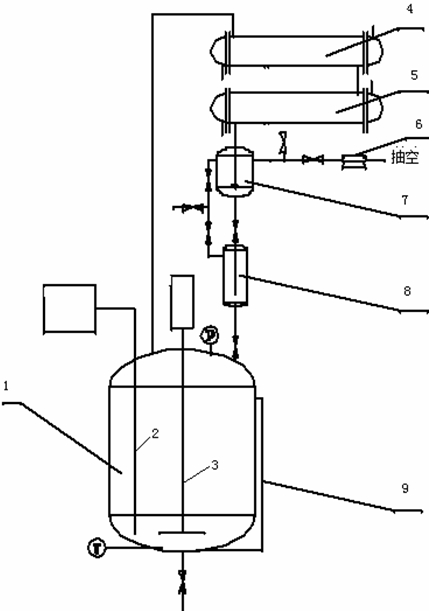

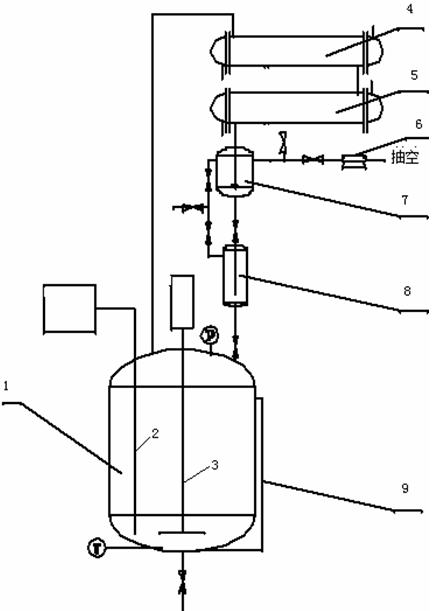

Reduced pressure ultrasonic combined extraction device

InactiveCN102198339AKeep aliveHigh extraction rateEnergy based chemical/physical/physico-chemical processesSolid solvent extractionNatural productEngineering

The invention discloses a reduced pressure ultrasonic combined extraction device, which comprises an extraction tank, a condenser, a cooler, and a gas-liquid separation device used for keeping the extraction tank positioned in a vacuum state, wherein the extraction tank, the condenser, the cooler and the gas-liquid separation device are connected end to end and form a circulation loop through a pipeline; and the device is characterized in that: an ultrasonic generating device and a stirring device are arranged below a liquid level inside a tank body of the extraction tank. The device can keep extraction always operated under a certain vacuum degree, reaches a boiling state at lower temperature, shortens the extraction time, improves the product yield and quality and keeps activity of a natural product; moreover, the extraction time can be shortened further due to arrangement of ultrasonic equipment, and ultrasonic waves dissolve out substrates in a cell wall more easily, so that the product yield is greatly improved. The reduced pressure ultrasonic combined extraction device has great application market in the extraction process.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for mining coalbed gas through V-shaped well set

The invention provides a method for mining coalbed gas through a V-shaped well set. The method comprises the steps that the V-shaped horizontal well set is a horizontal communication well set formed by connecting two horizontal wells and a vertical well in a butt joint mode at the same position, and is actually formed in the mode that the two U-shaped wells form a certain included angle and share the discharging and mining vertical well; and after the two horizontal wells communicate with the vertical well and are fractured, formation liquid are separately discharged through the two horizontal wells and flows into the same discharging and mining vertical well shaft. Mutual discharging, mining and depressurization gas production is achieved, the number of discharging and mining construction vertical wells is decreased, the effective supply range is widened, and the development cost is reduced; and by means of the height difference between the horizontal wells and a vertical well objective interval, water discharge and gas production are achieved through the vertical well, the transformation volume of a coal bed is increased, the permeability of the coal bed is improved, liquid loading in horizontal well sections is reduced, abrasion to a discharging and mining pipe column is relieved, the development effect of the coalbed gas is effectively improved, the average gas production rate per well reaches 4345 m<3> / d and is over four times that of a vertical well or above, and economic benefit prospects are good.

Owner:CHINA PETROLEUM & CHEM CORP

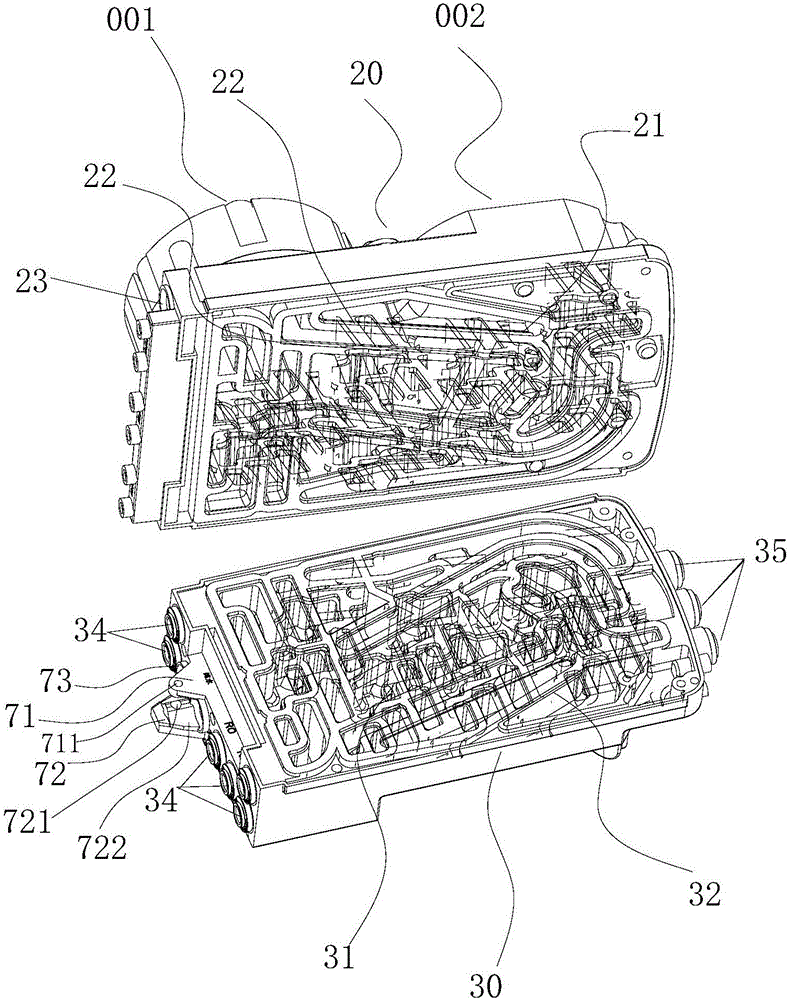

Integrated water path board

An integrated water path board is provided with an upper cover plate, a lower cover plate, a temperature sensor and a water quality senor. The upper cover plate is provided with a plurality of filter element seats, an upper water channel and first function piece connectors, and at least one filter element seat is used for assembling a composite filter element. The lower cover plate is provided with a lower water channel, second functional piece connectors, a plurality of water inlet pipe plugging ports, a line fixing mechanism and a pipeline fixing mechanism. The upper cover plate and the lower cover plate are assembled in a sealed mode, and thus the upper water channel and the lower water channel are correspondingly matched in a sealed mode to form a water channel with the corresponding function. The temperature sensor and the water quality sensor are assembled on the upper over plate, penetrate through the upper cover plate and stretch to the corresponding positions in the water channel. The integrated water path board is small in integral size and free of liquid leakage, and little accumulated water exists after water producing of the water channel is finished.

Owner:GUANGDONG LIZI TECH CO LTD

Chinese medicine preparation for treating arthromeningitis and preparation technique

ActiveCN101406548ASmall side effectsEasy to useAnthropod material medical ingredientsAntipyreticDiseaseSide effect

The invention discloses a traditional Chinese medicine preparation for treating synovitis, which is prepared for promoting blood circulation by removing blood stasis, relieving inflammation and pains, eliminating blood stasis and promoting tissue regeneration, on the basis of overview of traditional Chinese medicine on synovitis diseases and of modern medicine to pathogenesis and treatment principle. The preparation uses the following pure natural Chinese herbal medicine: pseudo-ginseng, safflower, gardenia, mastix, myrrh, rhubarb, pearl, nutgall and calculus bovis, which are combined according to the theory of traditional Chinese medicine and concocted respectively. The preparation has the advantages of quick medical effect, quick disappearance of clinical symptoms, small toxic and side effects, short treatment course, little pain, low cost and high primary healing rate, and can relieve the pain of a synovitis patient quickly.

Owner:宋文彬

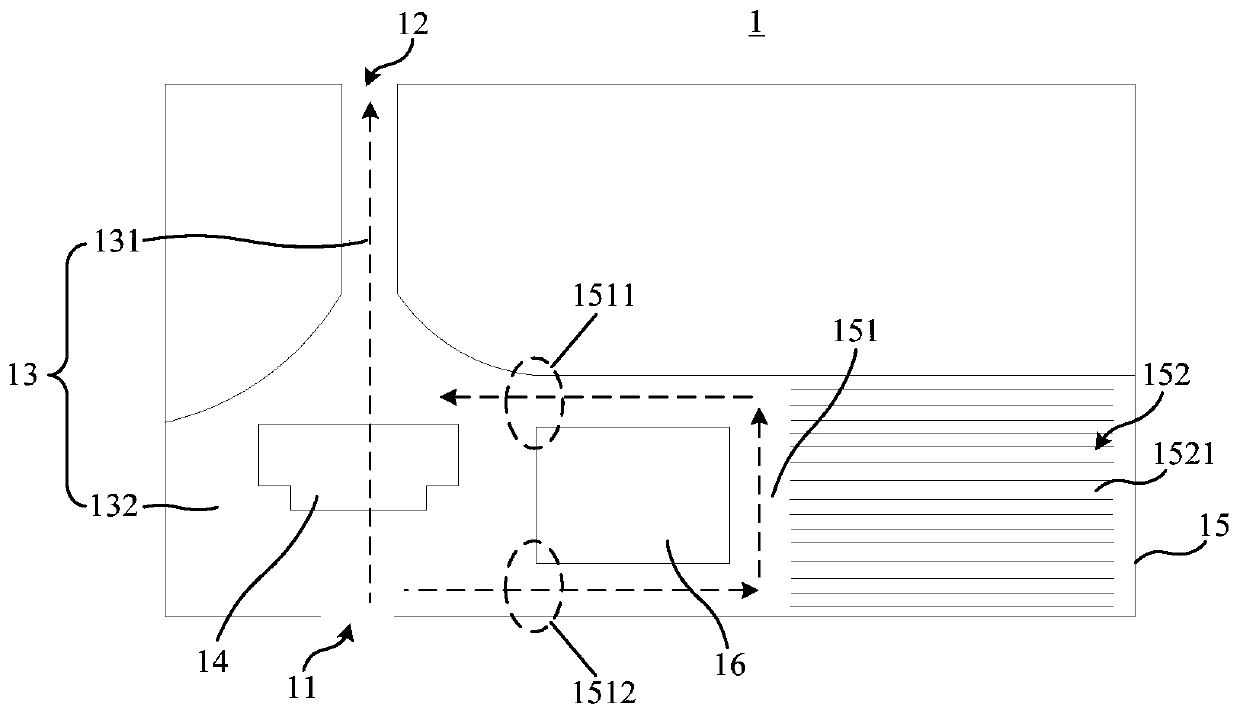

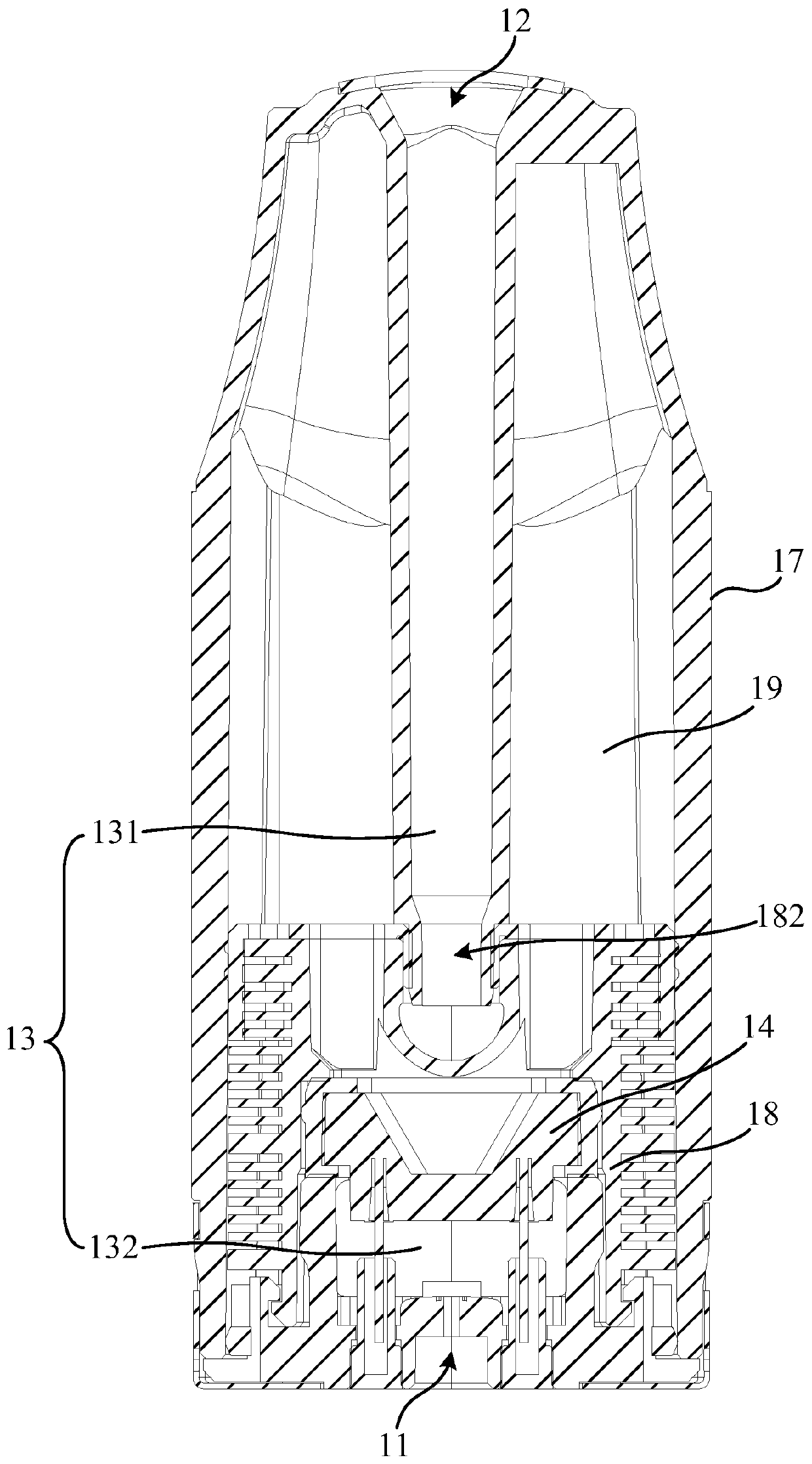

Atomizer and electronic atomization device

The invention relates to the technical field of electronic atomization devices, and discloses an atomizer and an electronic atomization device. The first intersection of the atomizer and the electronic atomization device is located between a first air outlet and an atomization assembly, and the second intersection of the atomizer and the electronic atomization device is located between the first air inlet and the atomization assembly. When the first air outlet performs suction action, air flow flowing from the first air inlet to the first air outlet can be generated in the first air flow channel, and the air pressure of the first air flow channel at the second intersection is larger than that of the second air flow channel at the second intersection. Therefore, the pressure difference between the first air flow channel and the second air flow channel at the second intersection can drive accumulated liquid, close to the second intersection, in the first air flow channel to enter the second air flow channel through the second intersection and be absorbed by the capillary liquid absorption structure. In this way, the situation of liquid leakage of the atomizer and the electronic atomization device can be relieved.

Owner:SHENZHEN SMOORE TECH LTD

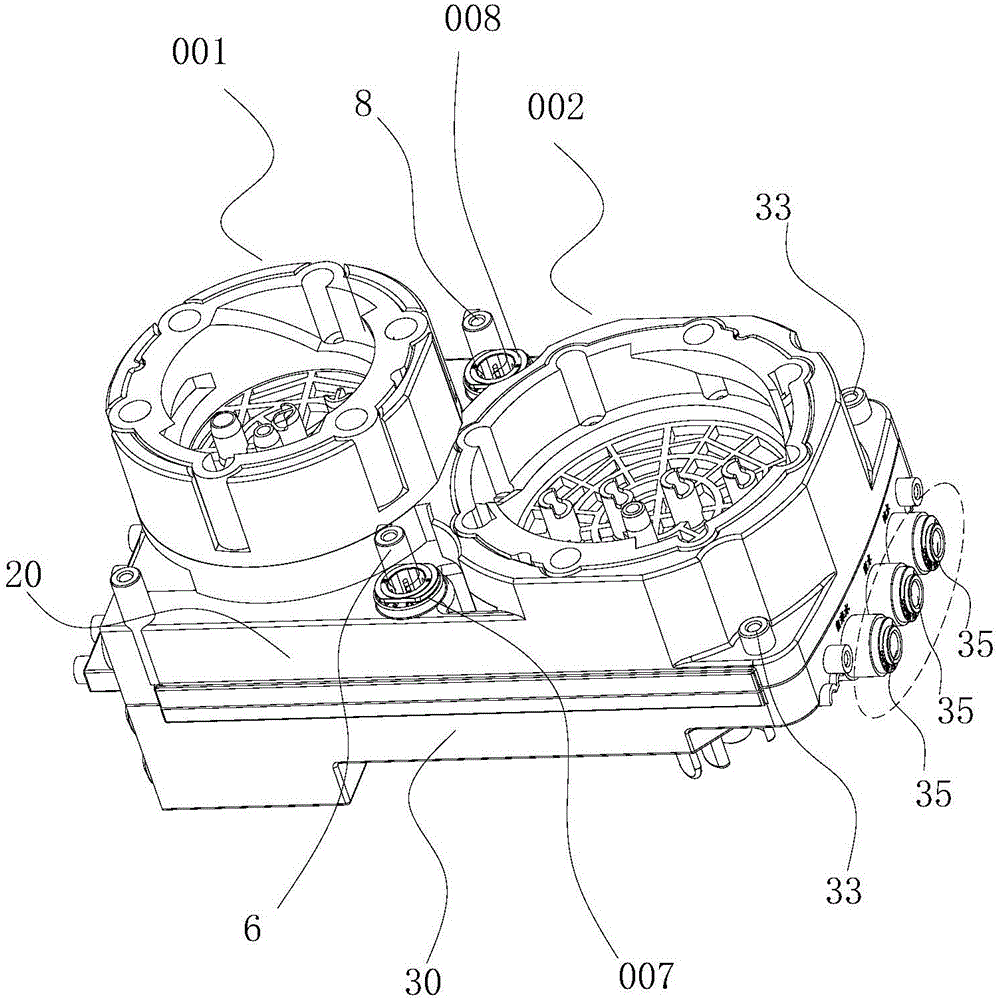

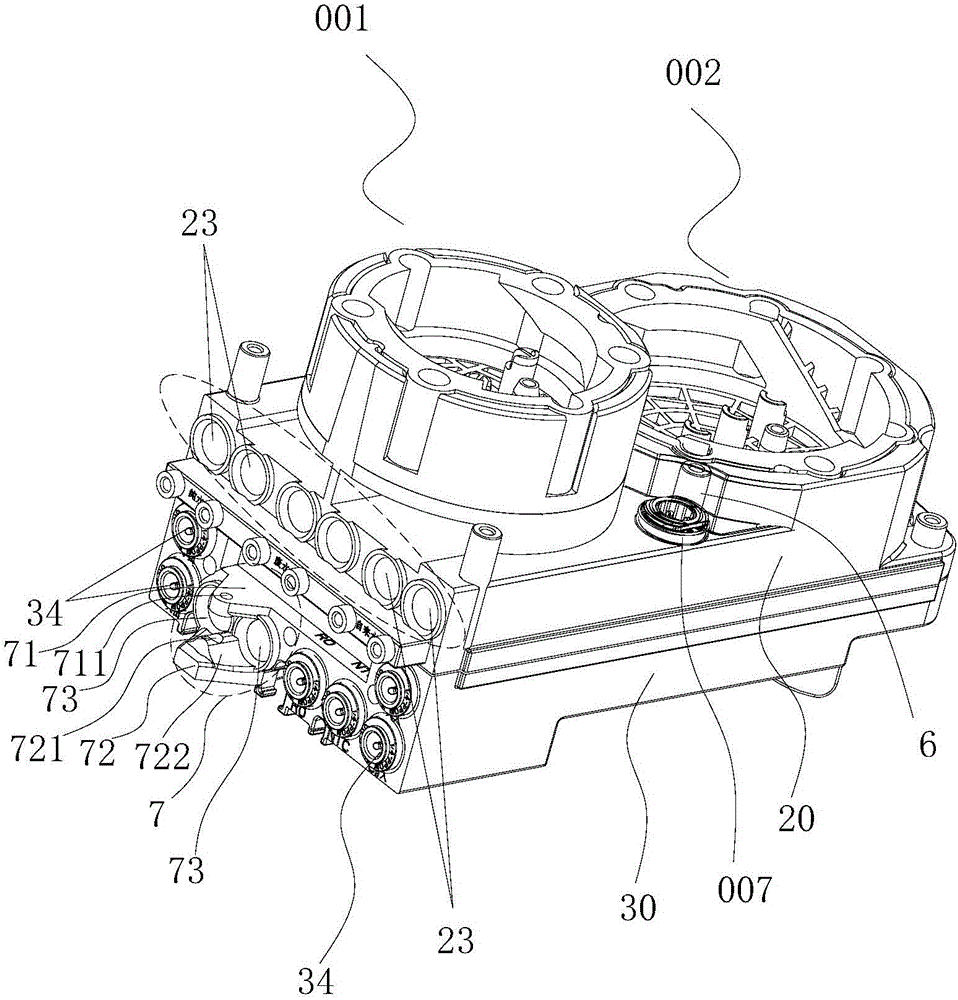

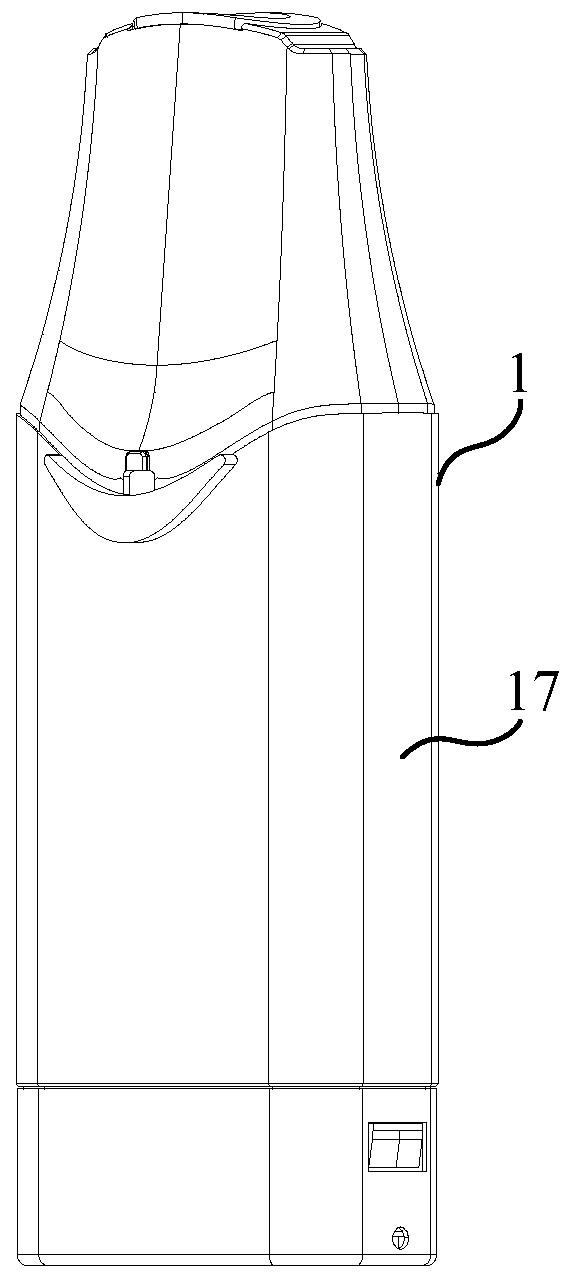

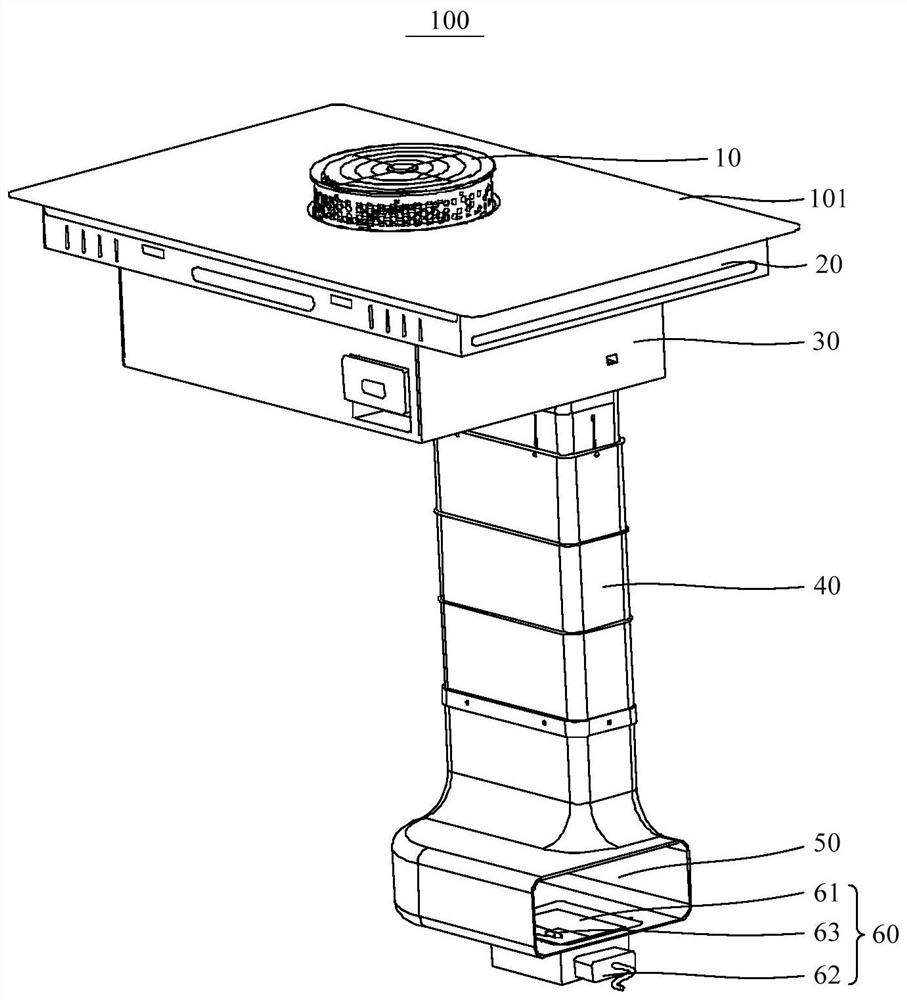

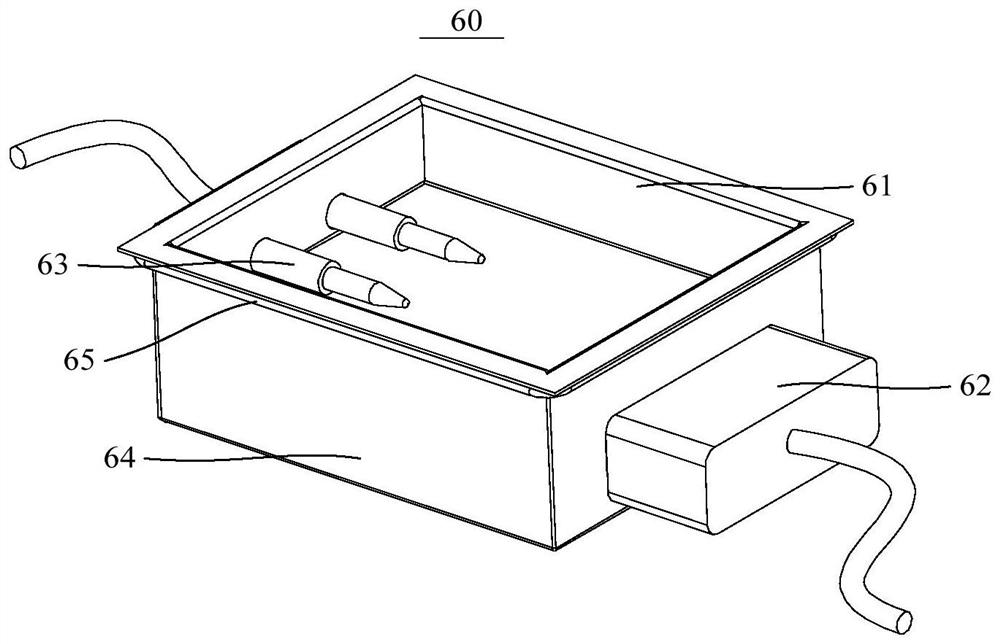

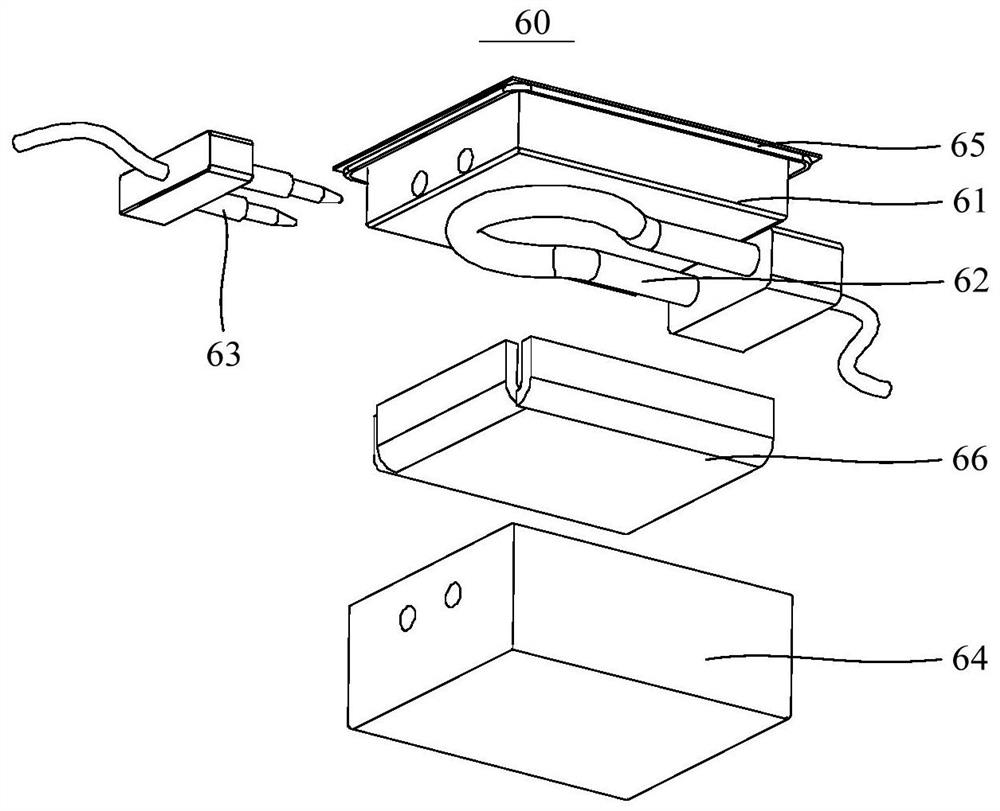

Smoke exhaust device and combined equipment with smoke exhaust device and cooking bench

ActiveCN111878866AReduce effusionImprove user experienceDomestic stoves or rangesLighting and heating apparatusEnvironmental geologySmoke

The invention relates to the technical field of extractor hoods, in particular to a smoke exhaust device and combined equipment with the smoke exhaust device and a cooking bench. The technical problemthat water is prone to accumulating in an existing smoke exhaust device is solved. In order to achieve the purpose, the smoke exhaust device is provided, the smoke exhaust device comprises a smoke suction cylinder, a smoke exhaust module and a heating module, the smoke suction cylinder is arranged at a smoke suction port of the cooking bench, and oil smoke generated by the cooking bench flows tothe smoke suction port through the smoke suction cylinder; the smoke exhaust module comprises a draught fan and a smoke exhaust cylinder, and the draught fan communicates with the smoke suction cylinder and the smoke exhaust cylinder and is used for sucking the oil smoke in the smoke suction cylinder into the smoke exhaust cylinder and exhausting the oil smoke; and the heating module is arranged in the smoke exhaust cylinder and used for heating and evaporating accumulated liquid in the smoke exhaust cylinder and discharging the accumulated liquid out of the smoke exhaust cylinder through thedraught fan. According to the smoke exhaust device, the accumulated liquid in the smoke exhaust cylinder can be heated and evaporated through the heating module and exhausted out of the smoke exhaustcylinder through the draught fan, so that the accumulated liquid in the smoke exhaust device is reduced, and the use experience of a user is improved.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG

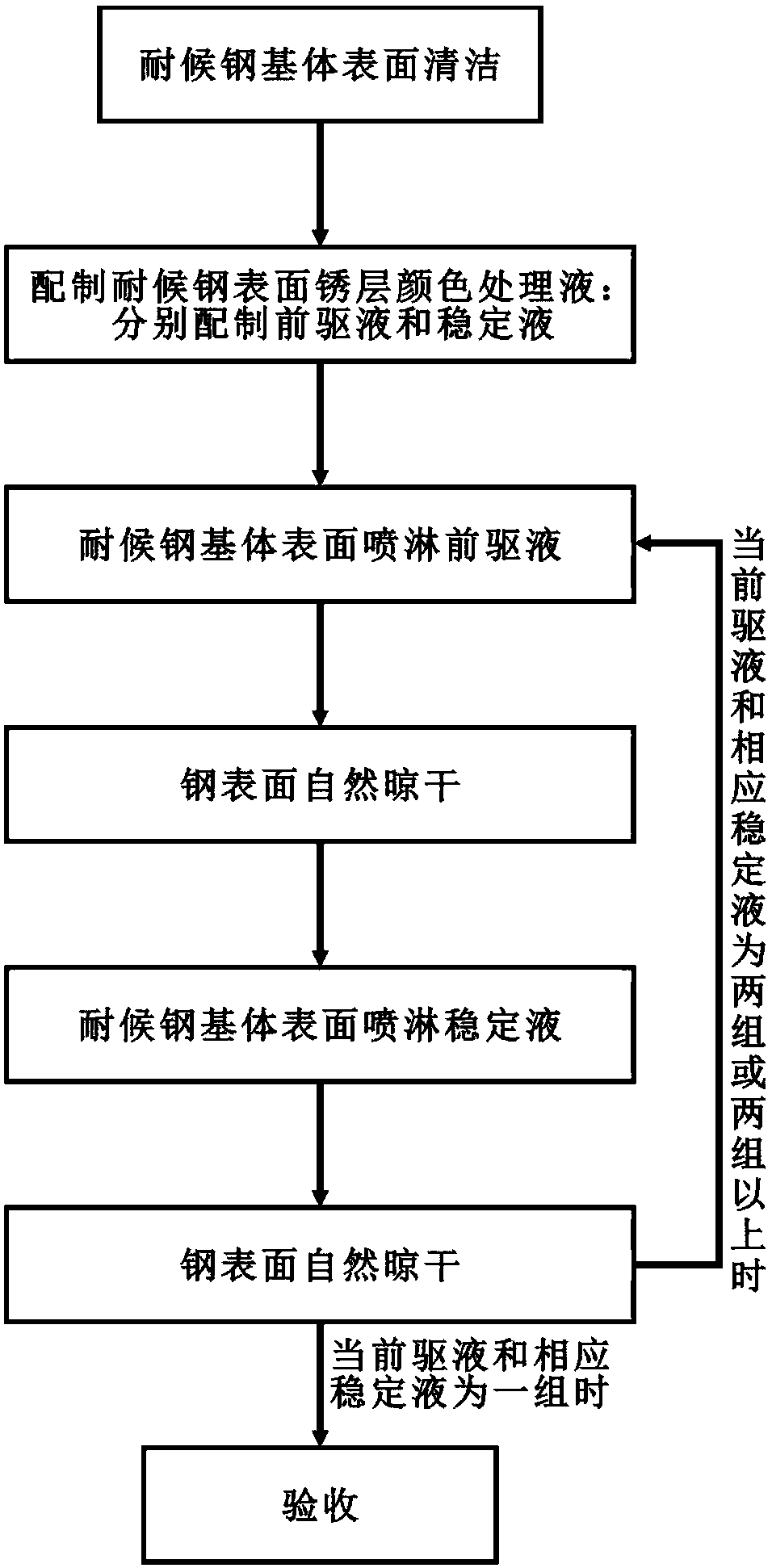

Conditioning fluid for regulating color of rust layer on surface of weathering resistant steel and treatment method thereof

ActiveCN107858672AThe formula raw materials are easy to getLow costMetallic material coating processesControllabilityWeathering steel

The invention belongs to the technical field of metal corrosion and protection, and relates to conditioning fluid for regulating the color of a rust layer on the surface of weathering resistant steeland a treatment method thereof. The conditioning fluid comprises a precursor solution for corrosion coloring of the surface of the weathering resistant steel, and a stabilizing solution for solidifying the color of the rust layer obtained after corrosion coloring of the surface of the weathering resistant steel. The precursor solution comprises one or two or more than two of a precursor solution body A which is used for enabling the rust layer of the surface of the weathering resistant steel to be red, a precursor solution body B which is used for enabling the rust layer of the surface of theweathering resistant steel to be yellow, and a precursor solution body C which is used for enabling the rust layer of the surface of the weathering resistant steel to be red with blue. According to the conditioning fluid and the treatment method thereof, by means of the theory that any color can be achieved by conducting composite mixing on the three primary colors, the precursor solution and thestabilizing solution are sequentially sprayed to the surface of the weathering resistant steel, an attractive visual effect is achieved under the situation that no coating is applied to the rust layerof the surface of the treated weathering resistant layer, and according to the three primary color combination theory, the color of the rust layer has the advantages of controllability and the like.

Owner:UNIV OF SCI & TECH BEIJING

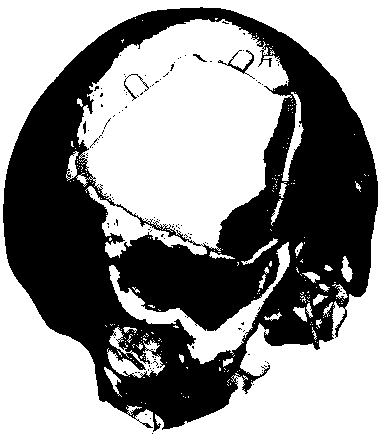

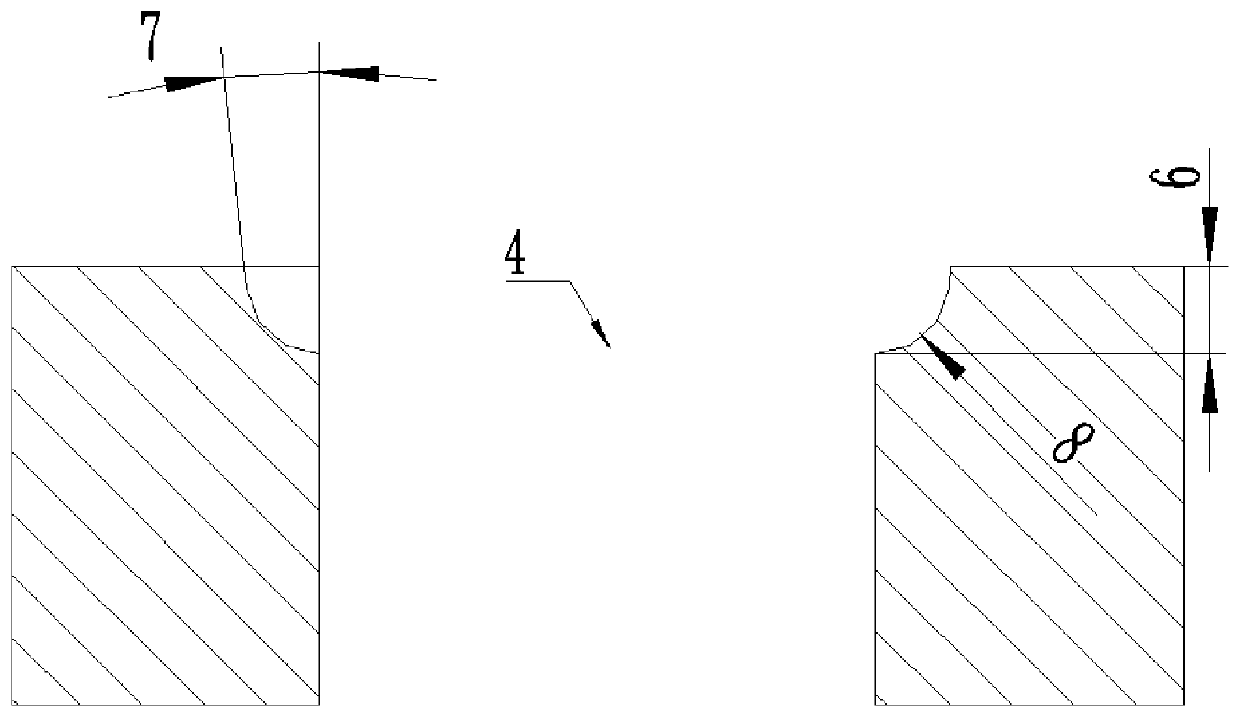

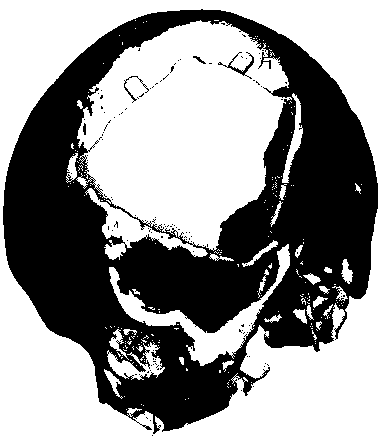

Method for manufacturing skull defect repair prosthesis

The invention discloses a method for manufacturing a skull defect repair prosthesis. The manufacturing method comprises the following steps of 1) acquiring CT scan data of a skull; 2) performing three-dimensional reconstruction based on the CT scan data to obtain a three-dimensional skull model; 3) delineating a bone window of a skull with defects based on the three-dimensional model of the skull,and selecting at least 2 positions at the edge of the bone window; 4) at the positions selected in step 3), extending a reference arc from the edge of the bone window; 5) generating an inner surfaceprosthesis template and an outer surface prosthesis template through the reference arc; 6) performing intersection on the inner surface prosthesis template and the outer surface prosthesis template, taking a superposition part as a three-dimensional model of a skull repair prosthesis; 7) obtaining the skull repair prosthesis three-dimensional model, and processing to obtain the skull repair prosthesis according to step 6). The curvature and thickness of the skull repair prosthesis made by the method are closer to an original skull, the accuracy level of the skull repair prosthesis is improved,and original shape and appearance of skull defect portions are well restored.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

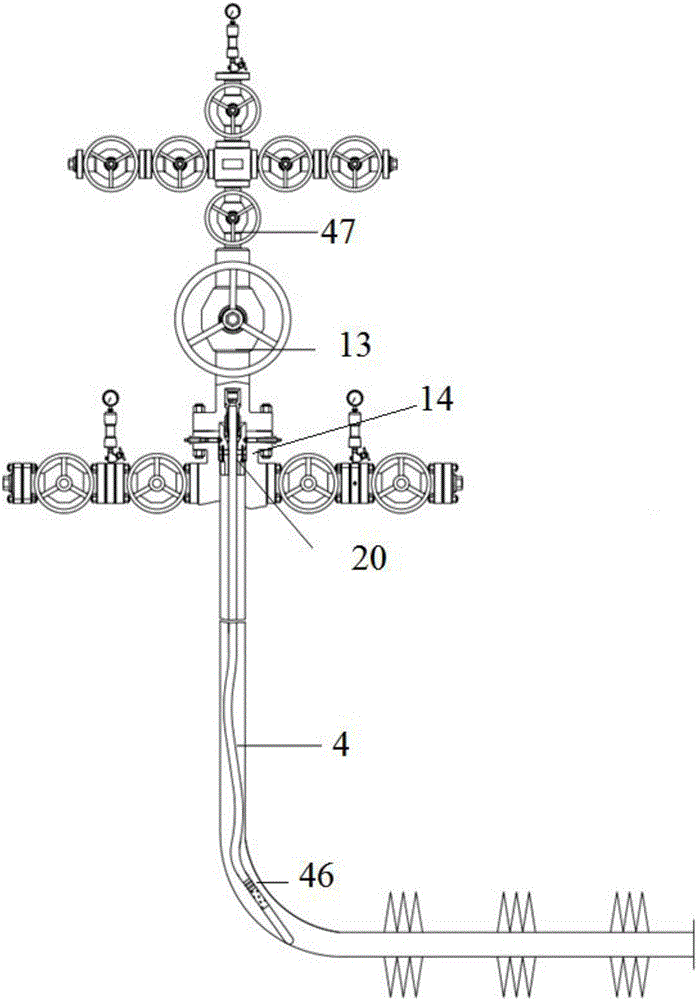

Built-in continuous oil tube well completion tube column and construction method thereof

The invention discloses a built-in continuous oil tube well completion tube column and a construction method thereof. The tube column comprises a built-in hanger, a continuous oil tube, a blocking device and a blocking rod. The upper end of the continuous oil tube is configured with the built-in hanger in a sealed mode and hung through the built-in hanger. The built-in hanger is arranged in a wellhead oil tube. The bottom of the continuous oil tube is connected with the blocking device. The blocking rod is used for being matched with the blocking device to secondarily seal the continuous oil tube when the well completion tube column is withdrawn. According to the built-in continuous oil tube well completion tube column and the construction method thereof, the built-in hanger at the upper end of the tube column is arranged in a wellhead oil tube head; when the pressure of the tube column under a well is abnormal, downhole airflow can be blocked off quickly by closing a first valve at a wellhead, and safety accidents are avoided. The tube column can achieve gas well extraction with liquid through the blocking function of the blocking device at the bottom of the tube column and the blocking rod matched with the blocking device, accumulated liquid in a pitshaft can be effectively relieved, return pressure at the shaft bottom is lowered, and the gas well extraction time is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Self-gas-production solid-foam liquor drainage ball of watered gas well

ActiveCN101671553BReduce effusionRelieve pressureFluid removalDrilling compositionHalf-lifeInjection equipment

The invention relates to a self-gas-production solid-foam liquor drainage ball of a watered gas well, which is applied to the technical field of the foam drainage gas-production technique. The liquor drainage ball mainly consists of a ball A and a ball B and is characterized in that the ball A contains the components by the weight ratio: 100-150 parts of sodium nitrite and 10-30 parts of foaming agent; and the ball B contains the components by the weight ratio: 100-120 parts of ammonium chloride, 5-10 parts of foam stabilizer, 25-40 parts of catalyst and 5-10 parts of ethylene diamine tetraacetic acid (EDTA). The liquor drainage ball has the effects that the foaming capacity is very good, and the liquor in the gas well can produce the over ten times of foam after the liquor drainage ball is put into the well; in addition, the foam is steady, the half-life period is long, and the liquor carrying capacity is very good. Both the ball A and the ball B are non-toxic, and the inertia and non-toxic gas can be produced after reaction. Moreover, the special high-pressure injection equipment is not needed in the process of the oil field operation, therefore, the technique is simple, and theoperation is convenient.

Owner:PETROCHINA CO LTD

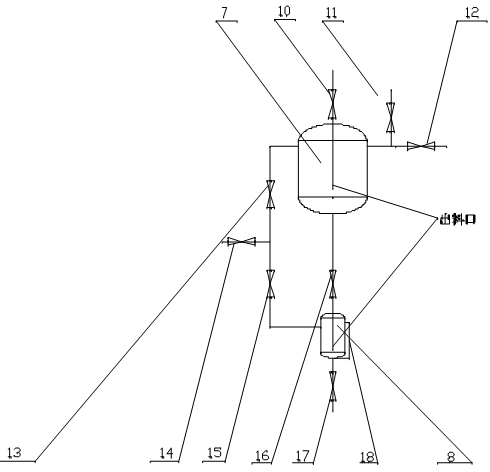

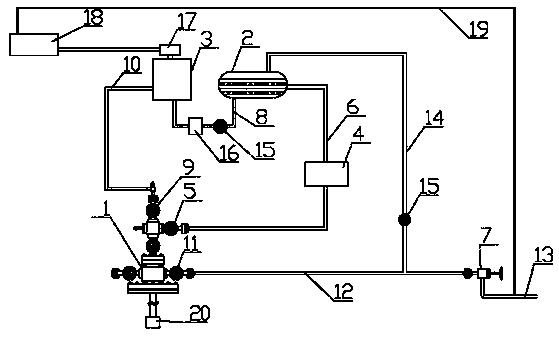

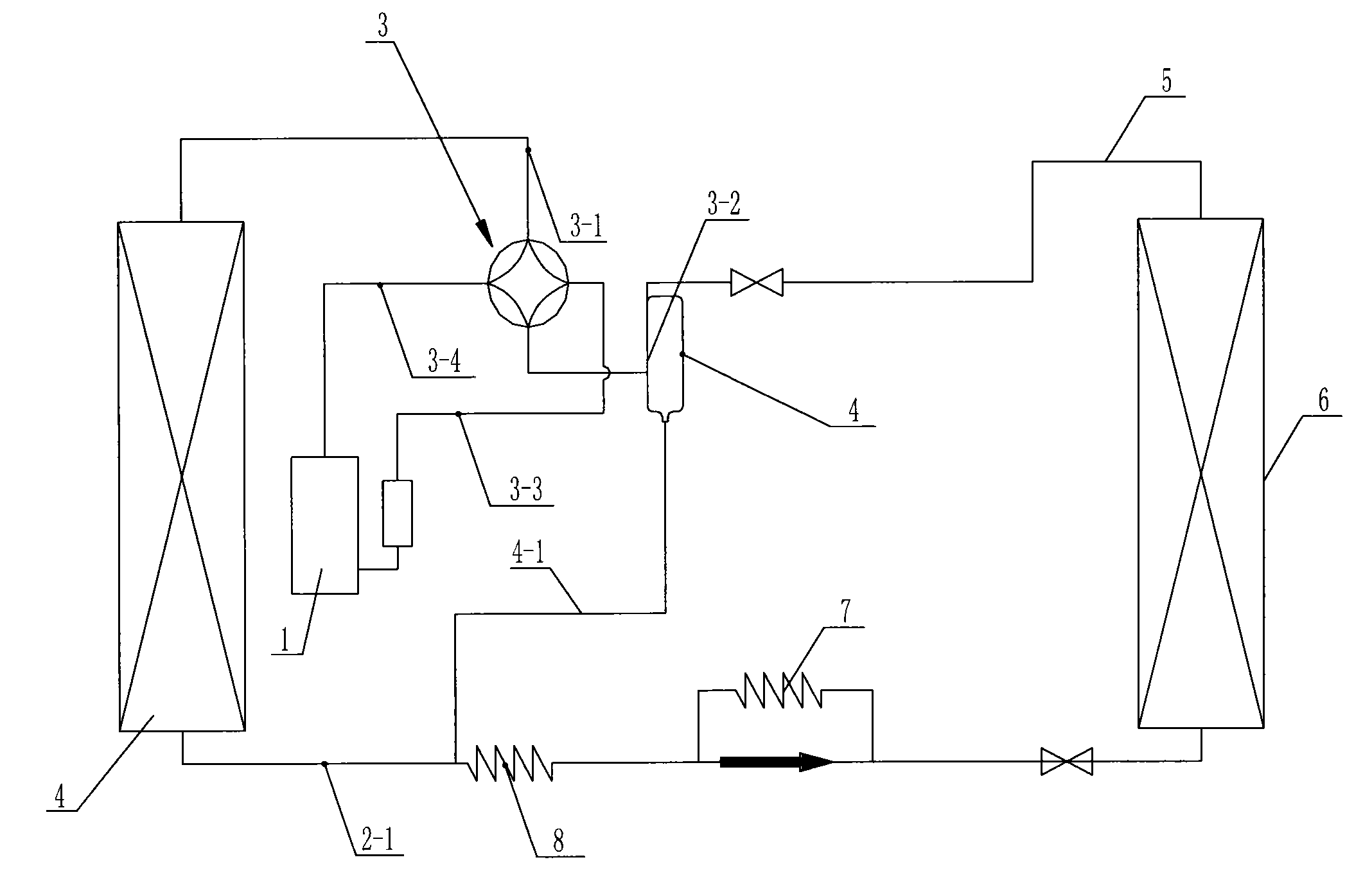

Concentric tube jet pump drainage gas recovery wellhead device and drainage gas recovery method thereof

InactiveCN110593799AReduce effusionResumption of productionFluid removalSealing/packingProduction rateRecovery method

The invention relates to the technical field of drainage gas recovery devices, in particular to concentric tube jet pump drainage gas recovery wellhead device and a drainage gas recovery method thereof. The device comprises a gas recovery tree, a gas and water separator and a plunger pump. A lower port of a casing pipe of the gas recovery tree fixedly communicates with an underground jet pump through an oil pipe, a mixed fluid pipeline communicates between a right side oil pipe gate valve of the gas recovery tree and an inlet of the gas and water separator, a power liquid pipeline communicatesbetween a water outlet in the bottom of the gas and water separator and a water inlet of the plunger pump, a high-pressure power liquid pipeline communicates between a water outlet of the plunger pump and a top gate valve of the gas recovery tree, a casing pipeline communicates with a right side casing pipe gate valve of the gas recovery tree, and a main gas transmission pipeline communicates with the outlet end of the casing pipeline. The concentric tube jet pump drainage gas recovery wellhead device is reasonable and compact in structure, and convenient to use, through combining of mechanisms such as the gas recovery tree, the gas and water separator, the plunger pump, the underground jet pump and the like, drainage gas production is achieved, the well cylinder accumulated liquid is reduced, the gas production rate is improved, and gas well production recovery can be achieved.

Owner:CNPC XIBU DRILLING ENG +1

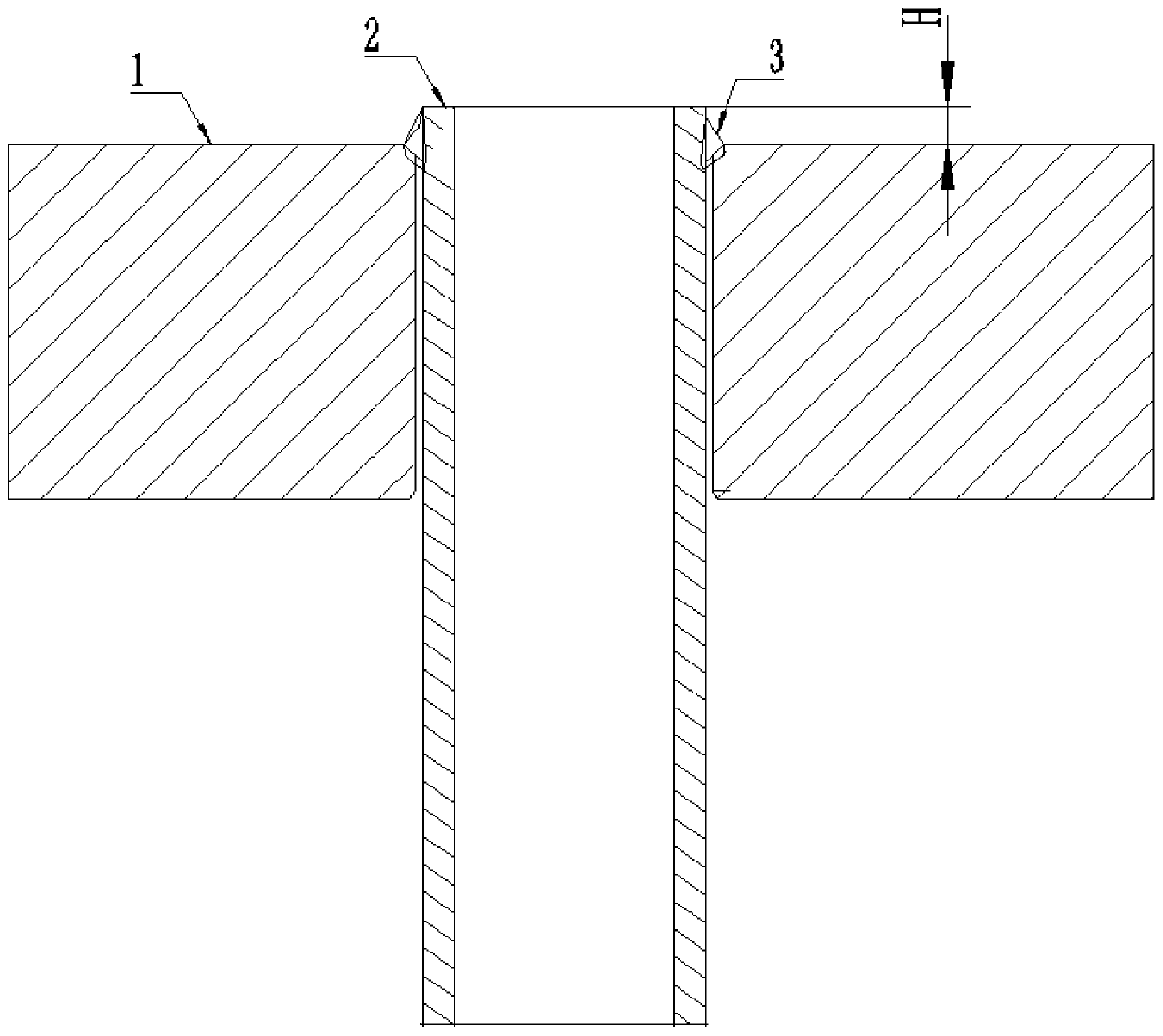

Heat exchange pipe and pipe plate welding method and application thereof

PendingCN110682024AAvoid corrosionEasy to integrateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWeld seam

The invention relates to the technical field of heat exchanger preparation, in particular to a heat exchange pipe and pipe plate welding method and application thereof. The method comprises the following steps of (1) chamfering at the edge of a pipe hole, and then inserting a heat exchange pipe into the pipe hole so as to be paired with a pipe plate, wherein the end port of the end to be welded ofthe heat exchange pipe is lower than the end surface of the pipe plate, but the pipe wall of the heat exchange pipe can always contact the wall surface of the pipe hole, and a 'U'-shaped groove is formed; and (2) welding the heat exchange pipe and the pipe plate which are assembled in the step (1), connecting the end surface of the pipe plate and the end port of the end to be welded of the heat exchange pipe through a welding seam, then processing the welding seam to form an arc shape, and enabling the form of the welding seam to be in a streamline shape. According to the heat exchange pipe and pipe plate welding method and the application thereof provided by the invention, the end port of the end to be welded of the heat exchange pipe is lower than the end surface of the pipe plate, namely, the heat exchange pipe is retracted for a certain distance relative to the end surface of the pipe plate, so that the form of the welding seam can be in the streamline shape, meanwhile, the thickness of the welding seam is larger than the thickness of a welding seam under a traditional welding manner, and the binding force between the heat exchange pipe and the pipe plate is improved.

Owner:LUXI IND EQUIP

Circulating and energy-saving device of air conditioner compressor

The invention discloses a circulating and energy-saving device of an air conditioner compressor. The circulating and energy-saving device comprises a gas-liquid separating device and a turbulator. The gas-liquid separating device is composed of a gas-liquid separation tank and a liquid collector, the inner side wall of the gas-liquid separation tank is coated with an elastic coating, one side of the gas-liquid separation tank is connected with an eccentric spray pipe serving as a condensing agent inlet, the liquid collector is located at the bottom of the gas-liquid separation tank and connected with the turbulator through a guide pipe, and an output port of the turbulator is connected with an expansion valve through a guide pipe. According to the circulating and energy-saving device, the gas-liquid separation tank can absorb high-pressure pulses, liquid accumulated in a condenser is reduced, liquid amount balance and heat dissipation amount increase of each part of a circulating system are adjusted along with environment temperature, the turbulator and an accelerator can reduce foams at the rear end of the expansion valve by using the adsorption principle, and therefore the evaporation effect is enhanced; the gas-liquid separation tank is properly matched with a refrigerating system in power, the working condition of a refrigerating unit can be improved, energy consumption can be reduced, the refrigerating effect is improved, high-pressure alarm is reduced, and the service life of the refrigerating system is prolonged.

Owner:周明

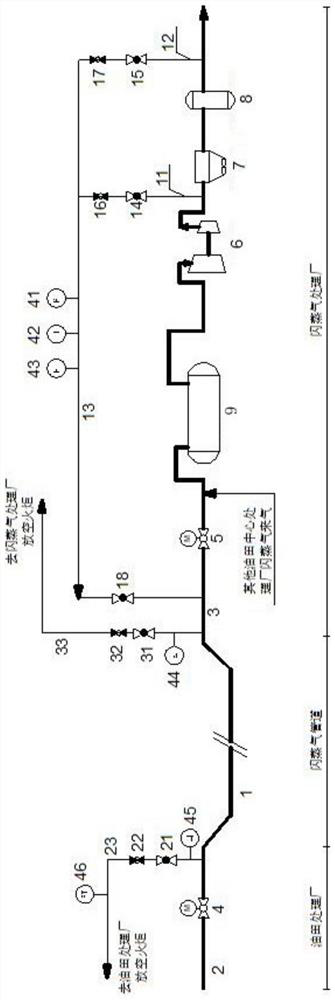

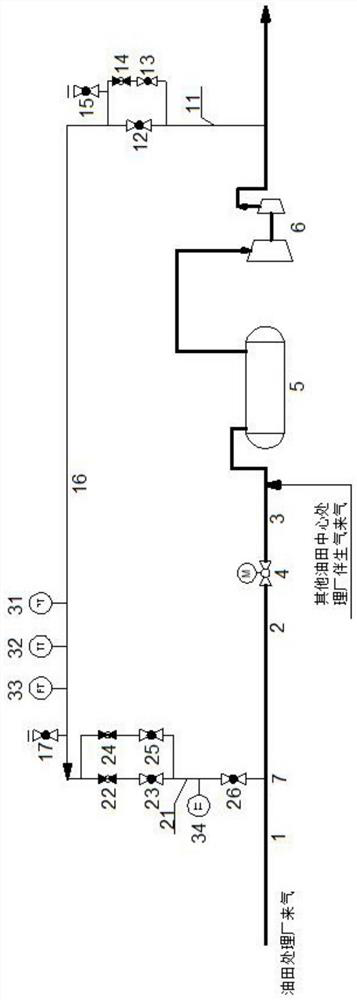

Oil field low-pressure flash steam pipeline conveying stopping accumulated liquid control system and method

PendingCN112178457AReduce the impactReduce effusionHollow article cleaningPipe elementsThermodynamicsControl system

The invention discloses an oil field low-pressure flash steam pipeline conveying stopping accumulated liquid control system and method. The system comprises a high-temperature gas reverse purging system, an upstream auxiliary pressure relief system, a flash steam treatment plant rapid relief system and a matched detection system. The high-temperature gas reverse purging system is used for providing high-temperature gas for a stopped flash steam main line, gasifying accumulated liquid in a pipeline and replacing a medium in the pipeline; the upstream auxiliary pressure relief system is used forreleasing flash steam in the reverse purging process of the flash steam pipeline after stopping conveying; the flash steam treatment plant rapid relief system is used for quickly releasing the mediumin the flash steam pipeline after stopping conveying or the flash steam pipeline directly releases when a treatment plant does not have reverse purge gas supply; and the matched detection system is used for detecting the temperature, the pressure and the flow of a required position in the system so as to provide an operation input signal and an input parameter. According to the system and the method, the accumulated liquid of the flash steam pipeline can be essentially and effectively controlled, and the influence on the restarting process is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

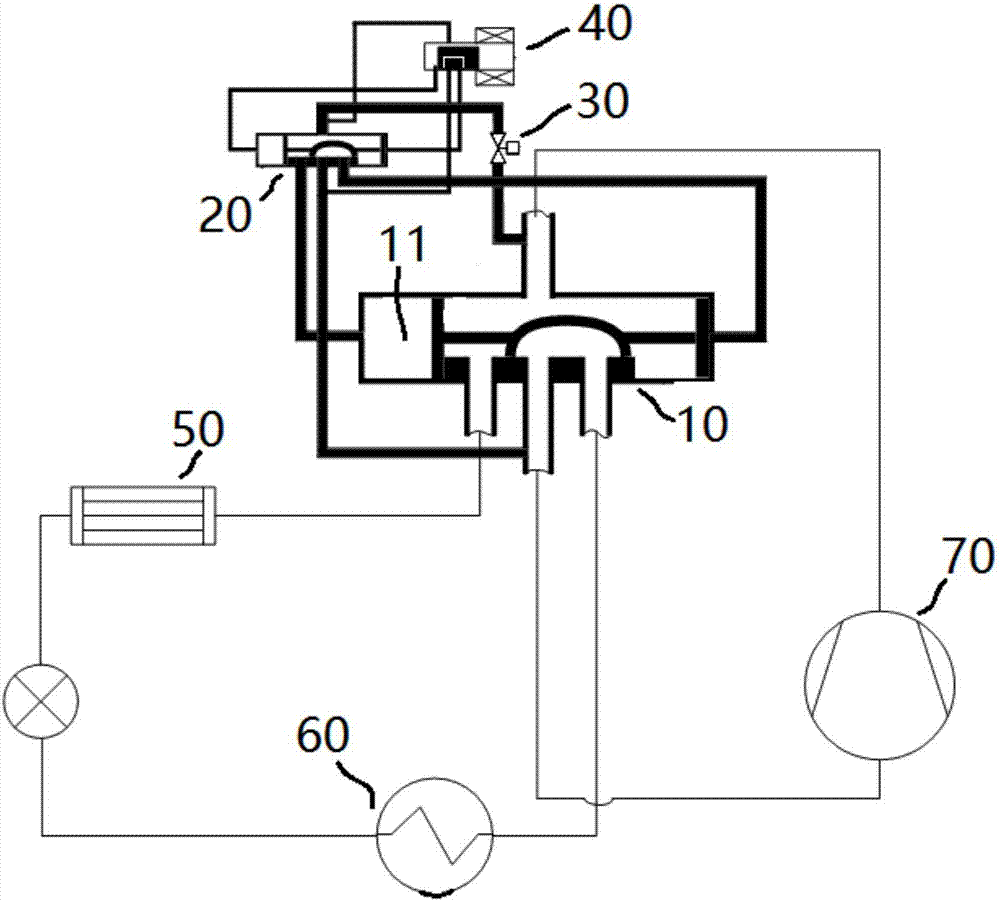

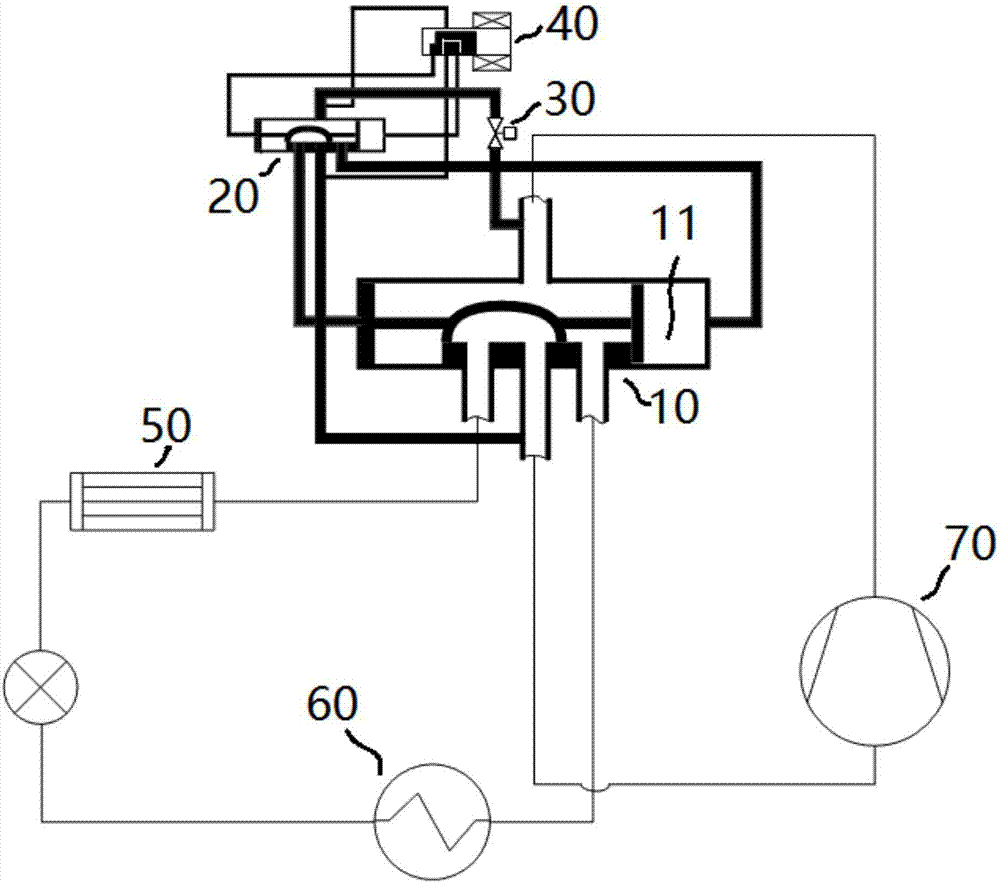

Four-way valve, refrigerating system and control method of refrigerating system

ActiveCN107990583ACommutation smoothReduce the amount of refrigerantMechanical apparatusFluid circulation arrangementFour-way valveEngineering

The invention provides a four-way valve, a refrigerating system and a control method of the refrigeration system. The four-way valve comprises a main four-way valve and a pilot four-way valve, whereinthe pilot four-way valve is connected with the main four-way valve, and is used for controlling the flow path direction in the main four-way valve; the main four-way valve comprises an liquid feedingport and three liquid reversing ports; and the four-way valve further comprises a flow path control valve, and the flow path control valve is arranged on a control liquid path where liquid feeding port of the main four-way valve and the pilot four-way valve are connected and is used for controlling connecting and disconnecting of the control liquid path so as to control the amount of the refrigerant entering a control hollow cavity of the main four-way valve through the pilot four-way valve. By applying the technical scheme, the influence of the accumulated liquid in the control hollow cavityon reversing of the main four-way valve can be avoided so that reversing of the four-way valve can be smoother, then normal operation of a unit can be guaranteed, and reversing noise can be reduced.

Owner:GREE ELECTRIC APPLIANCES INC

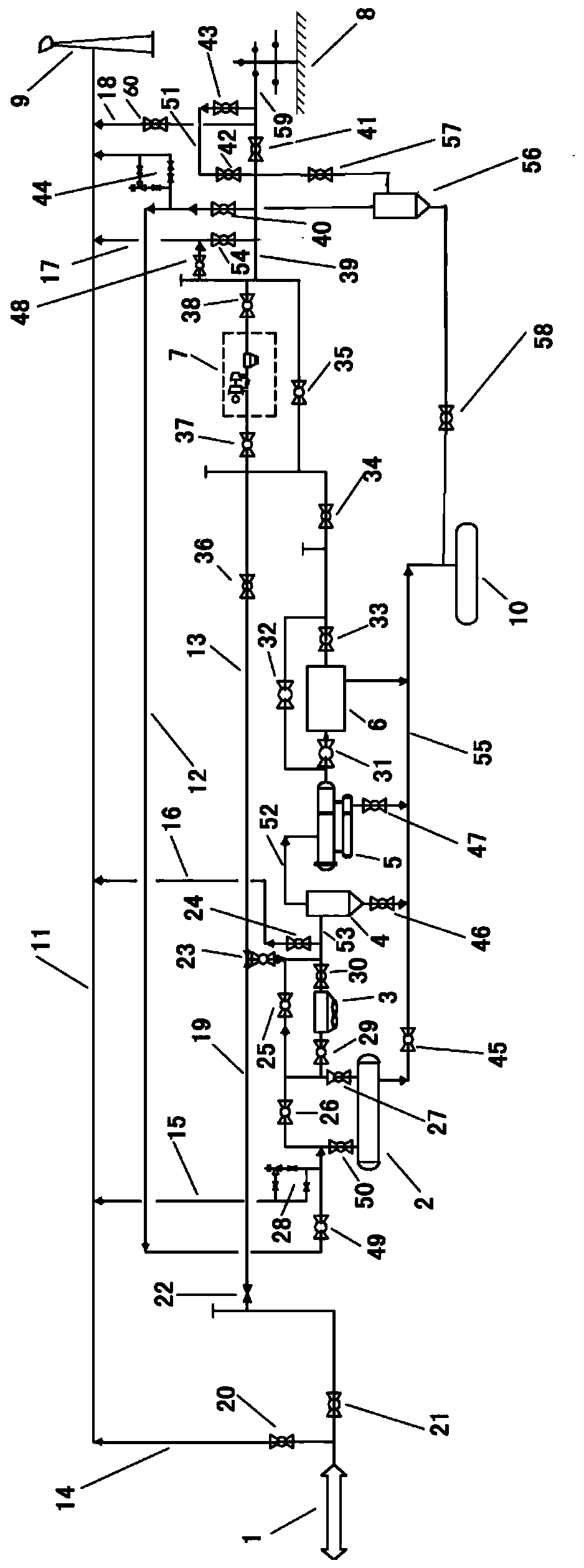

Ground gathering and conveying system for depleted gas storage

ActiveCN111256036AReduce the amount of constructionLow construction costGaseous fuelsPipeline systemsPhysicsWellhead

The invention belongs to the technical field of ground technological process and equipment of an underground gas storage, and particularly relates to a ground gathering and conveying system for a depleted gas storage. The ground gathering and conveying system for the depleted gas storage is installed between a wellhead of the gas storage and an outputting pipeline, and is connected through pipelines and valve groups. The ground gathering and conveying system comprises a slug flow catcher, an air cooler, a cyclone separator, a filtering separator, a triethylene glycol dewatering device, a natural gas compressor, an emptying torch, a metering separator, a produced water storage tank, a wellhead gas production tree, a valve group and an emptying valve group, wherein the valve group and the emptying valve group are arranged on a pipeline, and a liquid accumulation controller is arranged on the pipeline. According to the ground gathering and conveying system for the depleted gas storage, the same set of pipelines and devices are adopted as the gas injection and gas production technological process conveying system for the gas storage, so that the repeated use of the gas injection-gas production pipelines and devices is realized, and the construction amount and the construction cost are greatly reduced.

Owner:SINOPEC ZHONGYUAN PETROLEUM ENG DESIGN

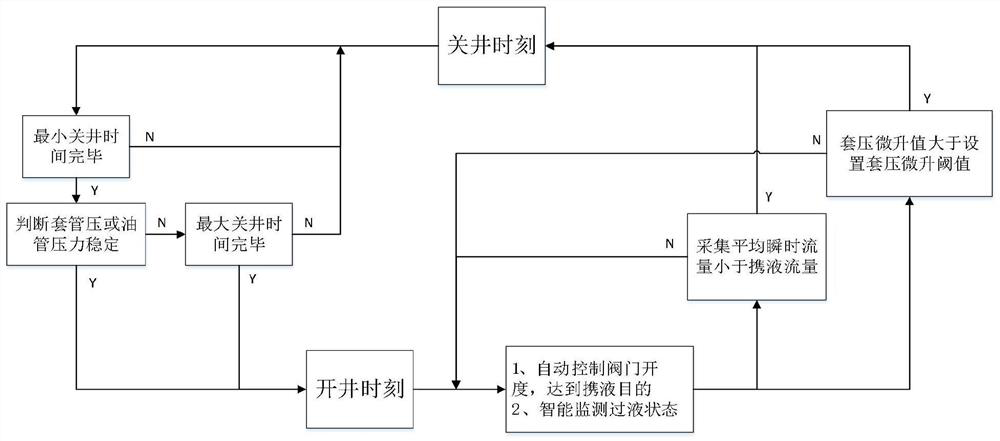

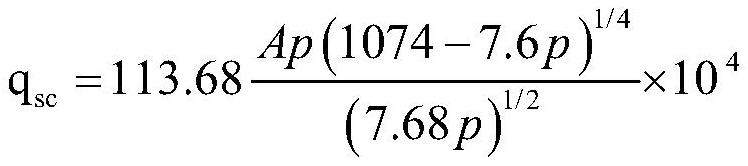

Natural gas well intelligent exploitation control method and device

PendingCN114233272AIncrease the number of pressure recoveryReduce bottomhole fluidSurveyFluid removalWellheadProcess engineering

The invention discloses an intelligent exploitation control method and device for a natural gas well, and the method comprises the steps: judging whether the pressure of a sleeve or the pressure of an oil pipe is stable or not after the countdown of the minimum well shut-in time is completed; when the pressure is stable, a valve on the gas production tree is controlled to open a well, and when the pressure is unstable, the valve on the gas production tree is controlled to open the well after the maximum well closing time is completed; by controlling the opening degree of a valve on the gas production tree, the instantaneous flow rate of the collection flow meter is larger than the liquid carrying flow rate; judging whether liquid passes through the pipeline or not; when liquid passes through, the wellhead pressure is controlled to be smaller than the cut-off pressure of the cut-off valve to increase the opening degree of the valve on the gas production tree, so that the liquid in the pipeline passes through; and when the average flow is smaller than the liquid carrying flow, a valve on the gas production tree is controlled to close the well, or when the casing pressure micro-rise value is larger than the casing pressure micro-rise value threshold value, the valve on the gas production tree is controlled to close the well. The time efficiency of opening and closing the well is improved, the liquid carrying capacity of the gas well is guaranteed, and the valve on the gas production tree is prevented from being frozen and blocked.

Owner:XIAN ANCN INTELLIGENT INSTR +1

A kind of manufacturing method of skull defect repair prosthesis

The invention discloses a method for making a skull defect repair prosthesis. The manufacturing method includes the following steps: 1) obtaining CT scan data of the skull; 2) performing three-dimensional reconstruction based on the CT scan data to obtain a three-dimensional model of the skull; At least 2 positions; 4) At the position selected in step 3), extend the reference arc from the edge of the bone window; 5) Generate the inner surface prosthesis template and the outer surface prosthesis template from the reference arc; 6) From the inner surface template Perform intersection calculation with the outer surface template, and take the overlapping part as the three-dimensional model of the cranioplasty prosthesis; 7) process the cranioplasty prosthesis based on the three-dimensional model of the cranioplasty prosthesis obtained in step 6). The radian and thickness of the cranioplasty prosthesis made by this method are closer to the original skull, the accuracy level of the cranioplasty prosthesis is improved, and the original shape of the skull defect is well restored.

Owner:MEDPRIN REGENERATIVE MEDICAL TECH

Apparatuses, systems, and methods for forming in-situ gel pills to lift liquids from horizontal wells

InactiveUS9664009B2Low viscosityIncrease gas productionCleaning apparatusFluid removalHorizontal wellsEngineering

Methods include the injection of a gelled, gelling or gellable composition into a horizontal section of a well at a location, where produced well gases or a combination of well gases and injected gases are sufficient to move the pill through the horizontal section into heal section, sweeping the horizontal section of accumulated liquids. Once in the heal section, the pill and the accumulated liquids are uplifted to the surface resulting in a cleaned well.

Owner:CLEARWATER INT LLC

Air-cooled cold and hot water unit

InactiveCN106595118AReduce effusionSolve the problem of suction with liquidMechanical apparatusCorrosion preventionSolenoid valveEngineering

The invention discloses an air-cooled cold and hot water unit. The air-cooled cold and hot water unit comprises a four-way reversing valve, a water side heat exchanger, a first electronic expansion valve and a wind side heat exchanger circularly connected in a circulating loop in sequence, and further comprises an auxiliary heat exchanger, a second electronic expansion valve, an electromagnetic valve, an auxiliary pipeline and a control valve, wherein the auxiliary heat exchanger is connected to a pipeline of the four-way reversing valve and the wind side heat exchanger; a parallel pipeline is formed between the second electronic expansion valve and the electromagnetic valve; the control valve is connected to the auxiliary pipeline and a pipeline between the four-way reversing valve and the water side heat exchanger; and the control valve is used for controlling communication between the four-way reversing valve and the water side heat exchanger or the communication between the four-way reversing valve and the auxiliary pipeline. The air-cooled cold and hot water unit is low in mechanical shock during defrosting, and prevents the inspiration of a compressor from taking liquid.

Owner:GREE ELECTRIC APPLIANCES INC

Control system and method for accumulated liquid in large-caliber flash steam pipeline in oil field

PendingCN112524487AIncrease medium temperatureImprove throughputPipeline systemsThermodynamicsControl system

The invention discloses a control system for accumulated liquid in a large-caliber flash steam pipeline in an oil field. The control system comprises a high-temperature mixed gas conveying system, a main line mixing system and a matched control system; the high-temperature mixed gas conveying system is used for taking out high-temperature pressurized gas from an outlet of a compressor and reversely conveying the high-temperature pressurized gas to the main line mixing system; the main line mixing system is used for regulating the pressure of high-temperature flash steam provided by the high-temperature mixed gas conveying system and then injecting the high-temperature flash steam into a predetermined mixing point at the tail section of a flash steam main line so as to heat and gasify the accumulated liquid at the tail section of the flash steam main line and purge the accumulated liquid; and the matched control system is used for controlling the flow of mixed gas and detecting the injection temperature of the mixed gas and the pressure of the conveying system. Based on the distribution rule and composition characteristics of the accumulated liquid in the flash steam pipeline in theoil field, a flash steam treatment plant can be used for pressurizing and providing the high-temperature flash steam to be reversely injected into the flash steam pipeline, so that the temperature and the conveying capacity of a medium at the tail section of the flash steam pipeline are improved, and most accumulated liquid at the tail section of the flash steam pipeline is gasified and carried to a downstream flash steam treatment plant, so that the accumulated liquid in the pipeline is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Air conditioning refrigeration circulating system and air conditioner

ActiveCN101936631AReduce effusionImprove heat transfer efficiencyFluid circulation arrangementFour-way valveEngineering

The invention provides an air conditioning refrigeration circulating system and an air conditioner, which can solve the problem brought by different coolant demand quantities by refrigeration and heating cycle in the prior art. The technical scheme is as follows: the air conditioning refrigeration circulating system comprises a compressor, a condenser, a four-way valve, a throttling device and an evaporimeter, wherein all components are connected by an online pipeline; the air conditioning refrigeration circulating system is also provided with a balance tank which is communicated with the outlet tube of the condenser via pipelines; and the body of the balance tank contacts with the E tube of the four-way valve. The invention utilizes the principles of degree of supercooling and degree of superheat, parts of coolant are stored in the balance tank during refrigeration circulation without participating in the refrigeration circulation, and parts of coolant participate in the refrigeration circulation during heat generation so as to obtain the purpose of balancing the filling amount of the coolant for refrigeration and heat generation.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

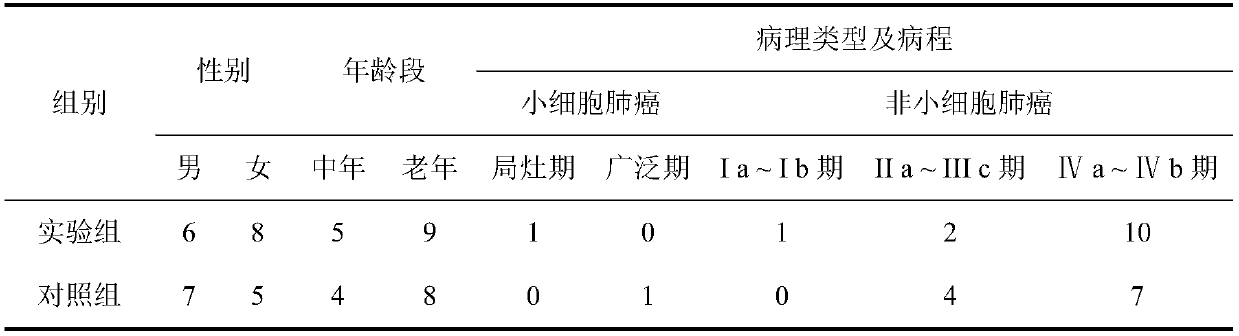

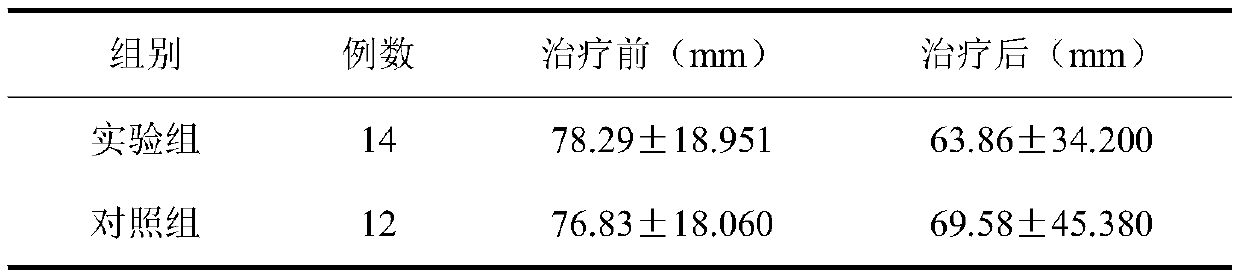

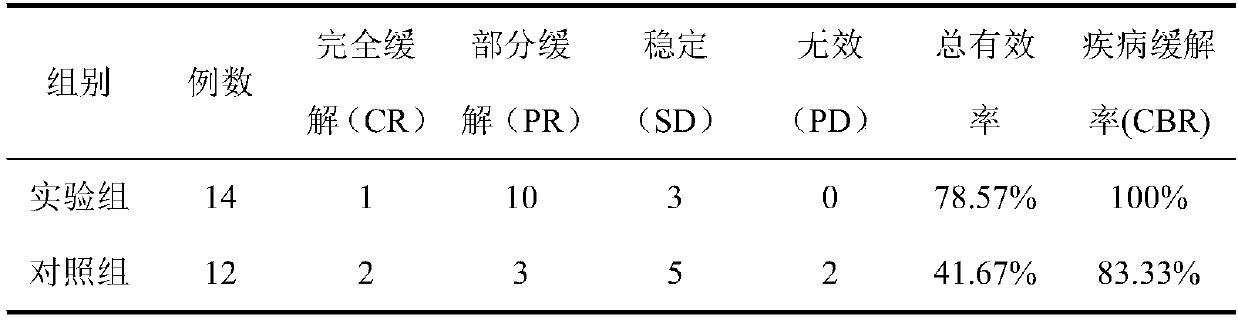

Traditional Chinese medicine composition for treating lung cancer with pleural effusion and preparation and applications thereof

InactiveCN109602790AReduce effusionRelieve symptomsAntineoplastic agentsSulfur/selenium/tellurium inorganic active ingredientsDisease remissionMirabilite

The invention relates to a traditional Chinese medicine composition for treating lung cancer with pleural effusion. The traditional Chinese medicine composition is prepared from the following raw material medicines in parts by weight: 13-19 parts of mirabilite, 2-6 parts of rhubarb roots and 1 part of gansui root. The invention also relates to a preparation method and applications of the traditional Chinese medicine composition. The medicines of the traditional Chinese medicine composition of the invention are orderly in compatibility, and supplement and complement one another. The compositionachieves the effects of softening hardness to dissipate stagnation and clearing heat to purge water, and can significantly reduce effusion and relieve symptoms, wherein the total effective rate (CR+PR) reaches 78.57%, and the disease remission rate (CBR) is as high as 100%. The composition effectively maintains therapeutic effect and has very good effect for the pleural effusion caused by lung cancer.

Owner:YUEYANG INTEGRATED TRADITIONAL CHINESE & WESTERN MEDICINE HOSPITAL SHANGHAI UNIV OF CHINESE TRADITIONAL MEDICINE

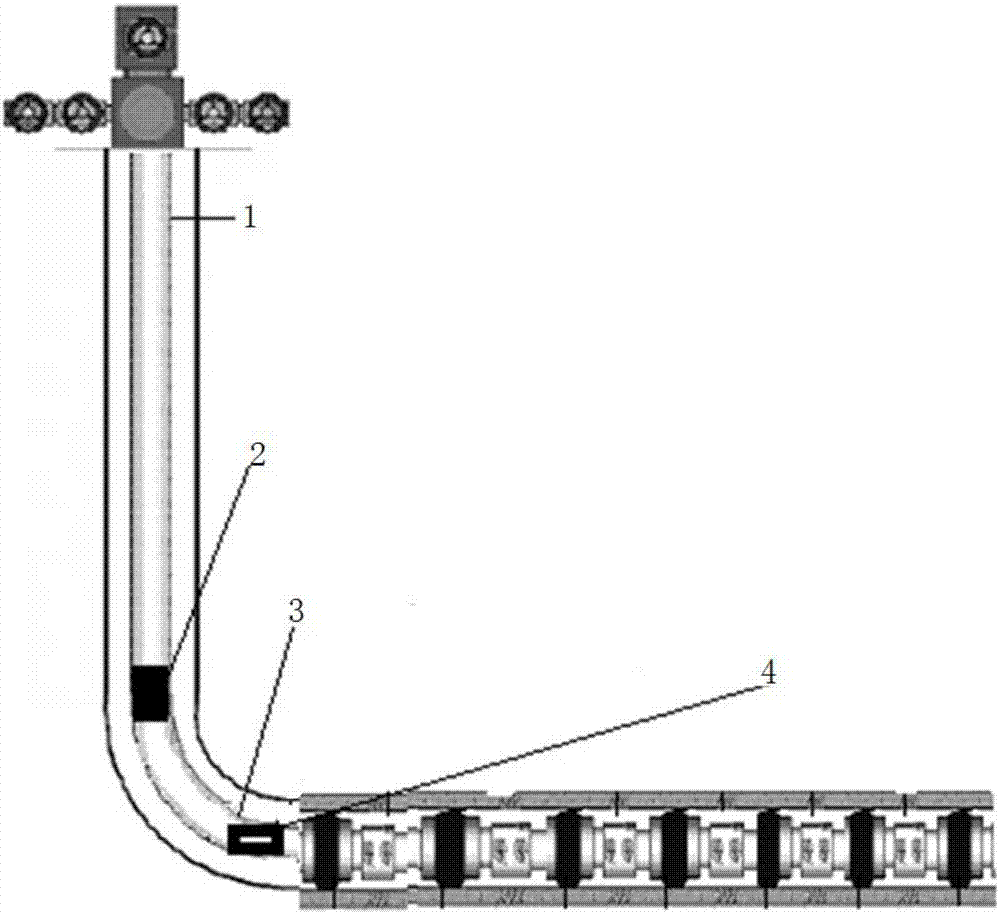

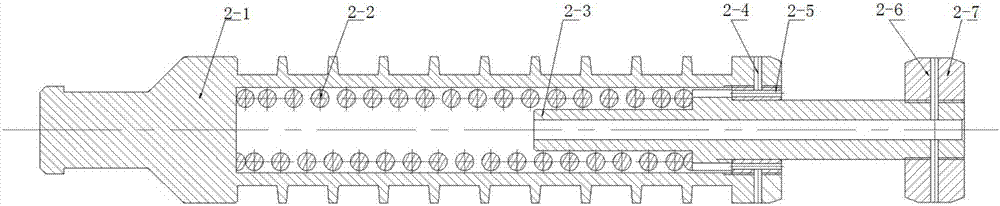

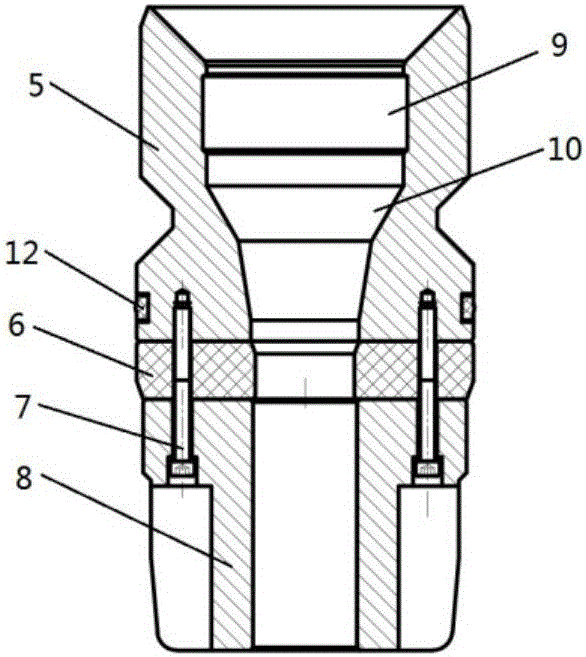

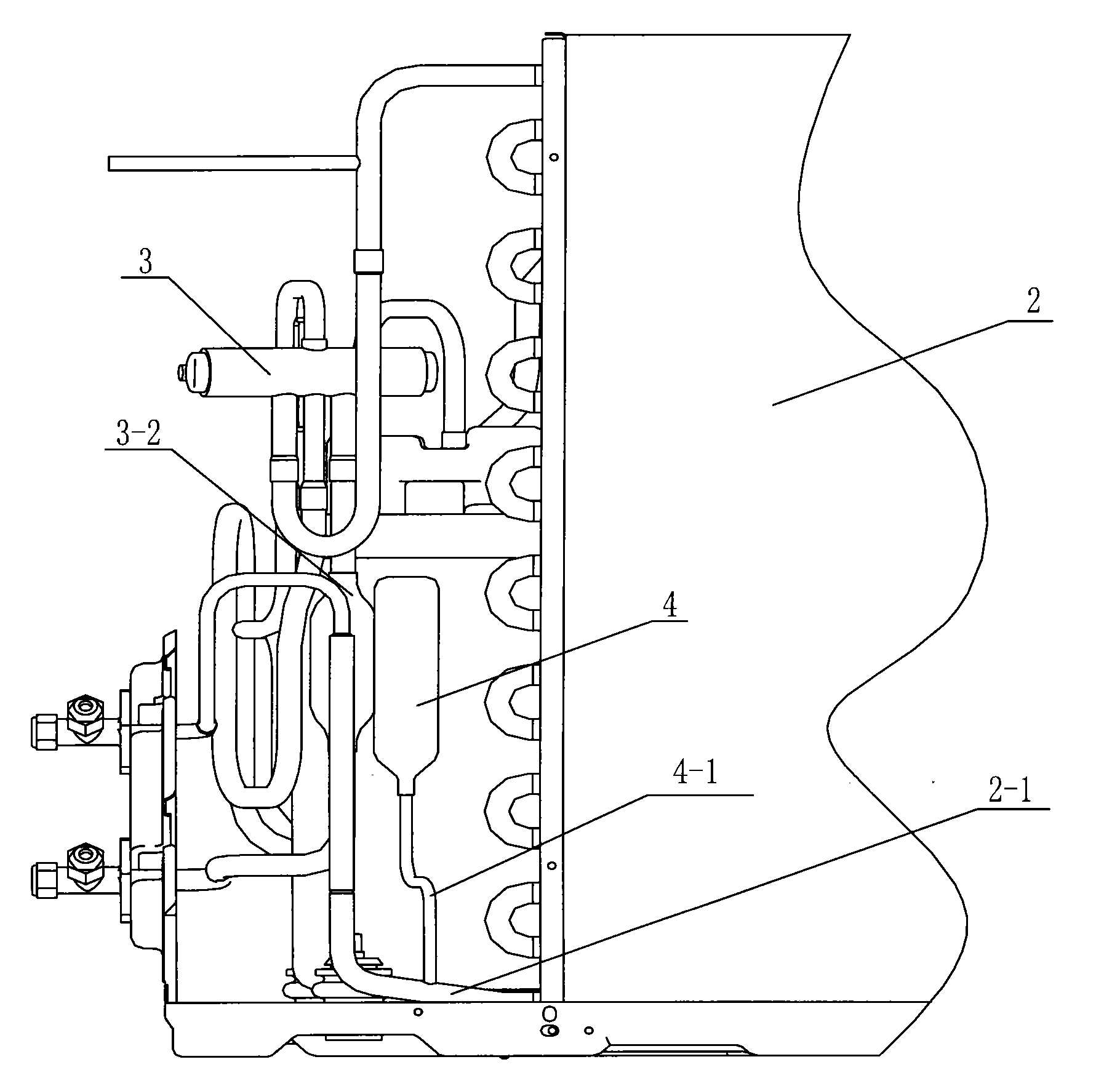

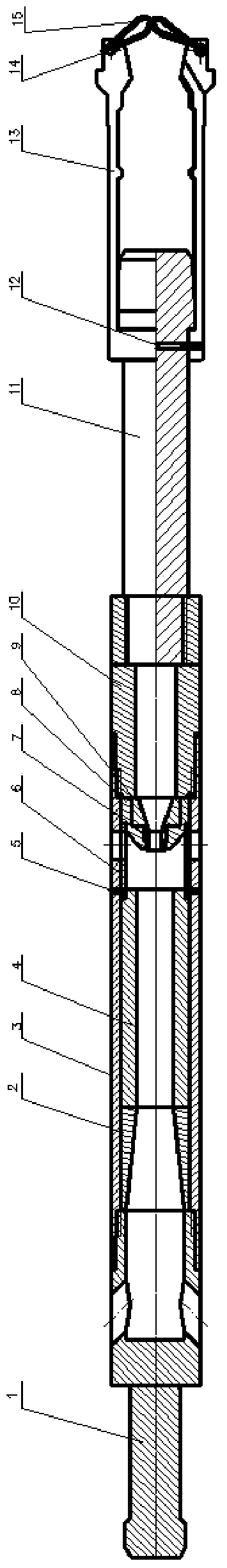

Injection tool and application method for drainage and gas production in cooperation with downhole vortex tool

The invention provides a spraying tool capable of being matched with an underground eddy current tool to realize water drainage and gas production and an application method of the spraying tool. The spraying tool capable of being matched with the underground eddy current tool to realize water drainage and gas production mainly consists of a salvage head (1), a diffusion pipe (2), a center pipe (3), a throat pipe (4), a pin (5), a nozzle position pipe (6), a spray nozzle (7), a spray nozzle support seat (8), a spray nozzle support pipe (9), a lower joint (10), a cone body (11), a shearing pin (12), a spring body (13), a spring pin (14) and a spring (15). The specific flowing state that the gas is in the center and the liquid flows along the pipe wall formed by the underground eddy current tool is used; the self energy of natural gas and a spray nozzle of a sprayer are used for realizing throttling and pressure reduction, so that the natural gas flow forms a pressure difference region in a mixing room; the well tube inner wall liquid flow is sucked; and the well tube liquid accumulation is reduced.

Owner:PETROCHINA CO LTD

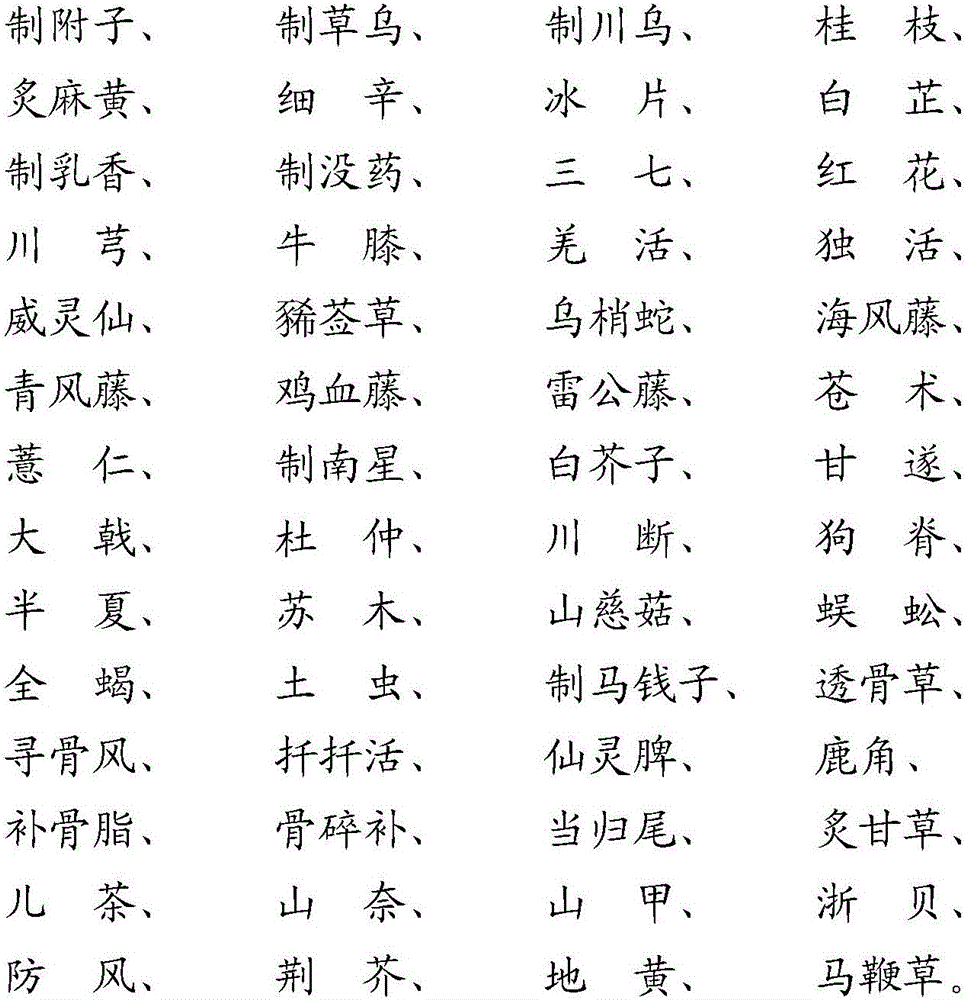

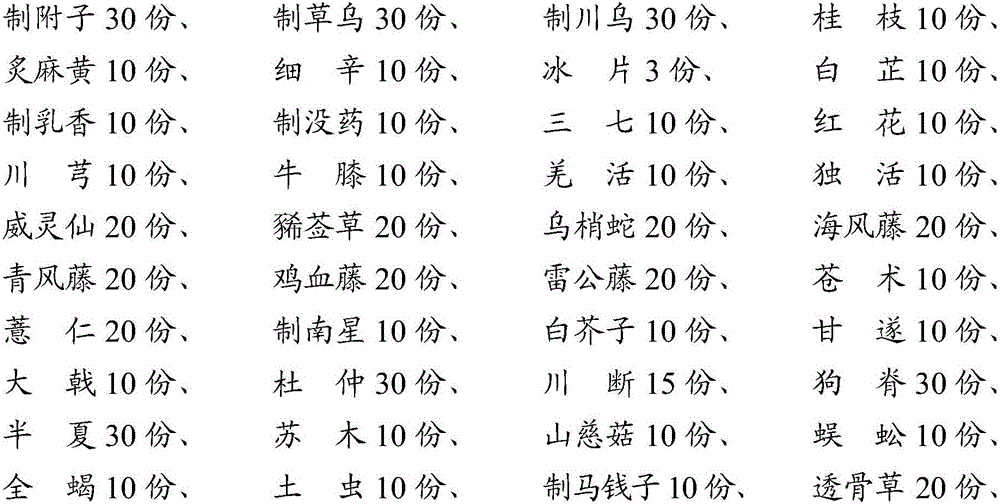

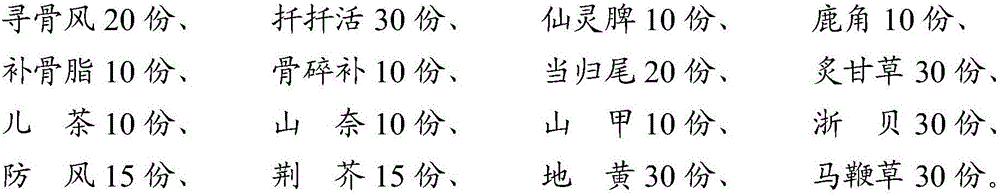

Traditional Chinese medicine composition and application thereof in preparing medicine for treating arthralgia

InactiveCN106215069AReduce effusionImprove outstandingAnthropod material medical ingredientsHydroxy compound active ingredientsJoint arthralgiaAntistreptolysin O

The invention relates to the field of traditional Chinese medicine, in particular to a traditional Chinese medicine composition and application thereof in preparing medicine for treating arthralgia. The traditional Chinese medicine composition is prepared from 56 medicinal materials, all the medicinal materials have a mutual effect in cooperation and jointly perform the functions of internally tonifying the spleen and the kidneys, externally dispelling wind, cold, damp, phlegm and blood stasis, and dredging channels and collaterals, and thus the traditional Chinese medicine composition has a good treatment effect on arthralgia. According to feedback of patients, the traditional Chinese medicine composition can reduce joint tendon sheath effusion, relieve interverebral disc herniation and reduce antistreptolysin O.

Owner:李景宏

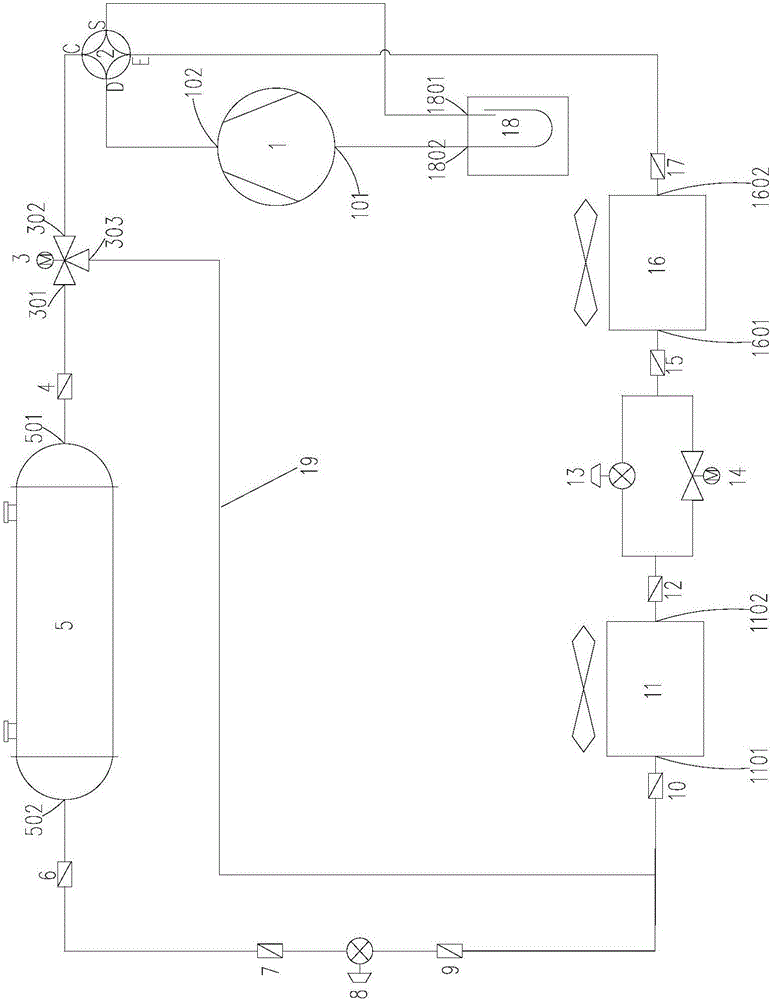

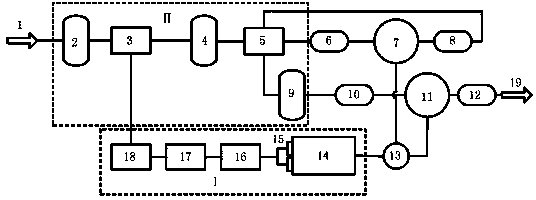

Multistage compression energy-saving utilization technology of overall fuel gas type natural gas compressor

InactiveCN103527314AImprove work efficiencyExtended service lifeInternal combustion piston enginesExhaust apparatusExhaust valvePneumatic motor

The invention relates to a multistage compression energy-saving utilization technology of an overall fuel gas type natural gas compressor. The multistage compression energy-saving utilization technology mainly relates to a gas engine tail gas complementary energy utilization system I and a natural gas separation and heat exchange system II for a natural gas compressor unit. The gas engine tail gas complementary energy utilization system I is mainly used for converting high-temperature heat energy of engine tail gas into kinetic energy of a pneumatic motor to further drive a refrigeration device to refrigerate manifold inlet gas, and the natural gas separation and heat exchange system II is used for refrigerating natural gas which is initially separated by a normal-temperature gravity separator to carry out low-temperature re-separation, then carrying out heat exchange on the re-separation gas before entering first-stage pressurizing and pressurized gas in a heat exchanger, and then enabling the gas to enter an interstage separator for next-stage pressurizing. Initial separation, low-temperature separation and interstage separation are carried out on the manifold inlet gas, the work efficiency of the compressor unit can be improved, gas consumption for the per-unit yield of the compressor unit is reduced, energy sources are saved, internal accumulated liquid of a compression cylinder can also be reduced, and the service life of the compression cylinder of the compressor unit and the service life of a gas inlet-and-outlet valve are prolonged.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com