Method for mining coalbed gas through V-shaped well set

A mining method and technology for coalbed methane, which are applied in the fields of mining fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of time-consuming and labor-intensive, small reformation area, high development cost, etc., and improve the reformation volume and permeability. high performance, high economic prospects, and the effect of improving the development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

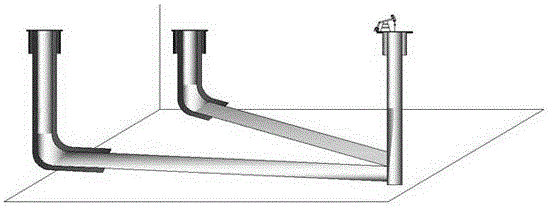

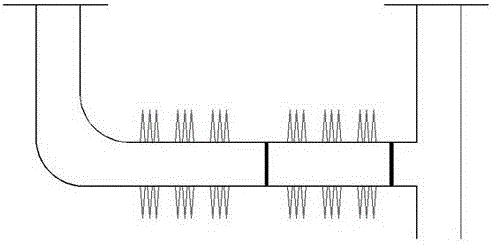

[0013] As shown in the figure, a V-shaped well group mining method for coalbed methane, the steps are as follows:

[0014] The first step is milling and drilling V-shaped well group: V-shaped well group is composed of one vertical well and two horizontal wells. The vertical well is drilled first, and then two horizontal wells are drilled. The two horizontal wells and the vertical well are connected at the same position to form a V-shaped well. According to the change of the natural inclination angle of the coal seam, the trajectory of the horizontal well is located at the high part of the structure of the target layer, and the vertical well is located at the low part of the structure; after the milling and drilling of the vertical well, steel casing cementing is used; Hole construction, the diameter of the cave is 0.5m, so that the horizontal well and the vertical well with a distance of nearly one thousand meters are accurately docked; due to the difficulty of multi-hole cemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com