Conditioning fluid for regulating color of rust layer on surface of weathering resistant steel and treatment method thereof

A treatment method and technology of weathering steel, applied in the direction of metal material coating process, etc., can solve the problems of unsustainable color, difficult large-scale components, unselectable, etc., and achieve the effect of beautiful color, uniform color of rust layer, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

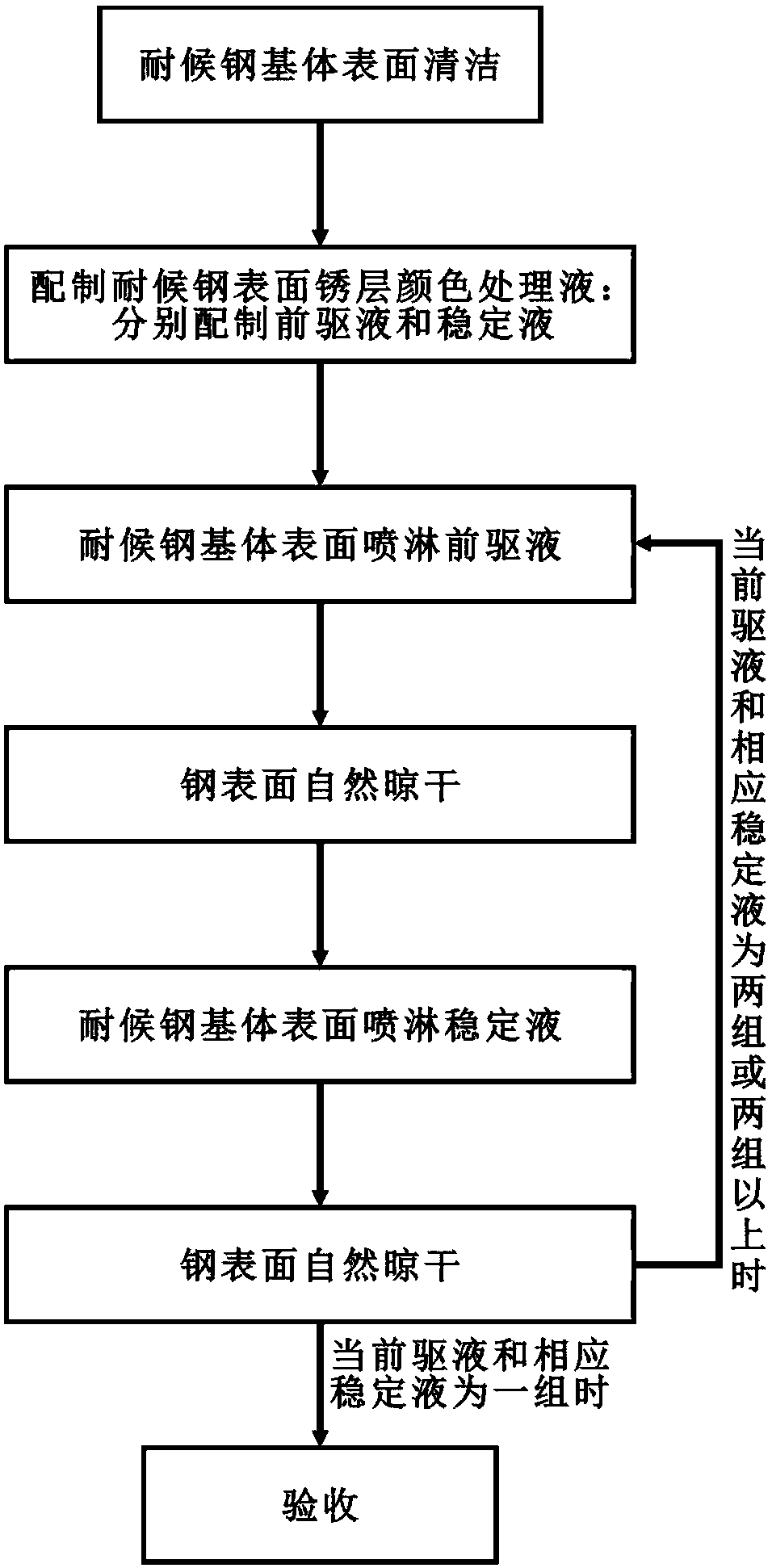

[0052] The present embodiment provides a kind of processing method of regulating and controlling the color treatment liquid of the rust layer on the surface of weathering steel, such as figure 1 As shown, the processing method includes the following steps:

[0053] 1) Surface cleaning of weathering steel: remove the scale on the surface of weathering steel by shot blasting or pickling, cut into 40mm×40mm weathering steel sheets, degrease with acetone, grind the experimental weathering steel to 600# with sandpaper, and finally use Clean with absolute ethanol and blow dry;

[0054] 2) Preparation of weather-resistant steel surface rust layer color treatment solution: the treatment solution includes a precursor solution and a corresponding stabilizing solution, and 500 g is prepared respectively according to their respective mass fractions to obtain a precursor solution and a corresponding stabilizing solution with uniform solute;

[0055] 3) Corrosion and coloring of weathering...

Embodiment 2

[0064] The processing method of this embodiment is basically the same as that of Embodiment 1, except that:

[0065] The precursor liquid is liquid B, and the corresponding stable liquid is liquid b.

[0066] The mass fraction of each component in the precursor liquid B is: 0.5% to 3.5% NaCl, 0.1% to 2% FeSO 4 , 0.1%~1%CuSO 4 , 0.1%~2%NaHSO 3 , and the balance is water.

[0067] The mass fraction of each component in the stable solution b is: 0.8% to 2% NaCl, 0.3% to 1.5% FeSO 4 , 0.2%~0.8%CuSO 4 ,0.1%~0.3%NaNO 3 , and the balance is water.

[0068] Adding mass fraction range of 40% absolute ethanol to the precursor liquid B liquid to replace the same mass fraction of water in the precursor liquid B liquid, and then spraying the surface of the weathering steel to promote rusting of the weathering steel surface. Layers dry quickly.

[0069] Adding anhydrous ethanol with a mass fraction range of 1% to the stabilizing liquid b to replace water of the same mass fraction in...

Embodiment 3

[0072] The processing method of this embodiment is basically the same as that of Embodiment 1, except that:

[0073] The precursor liquid is liquid C, and the corresponding stable liquid is liquid c.

[0074] The mass fractions of the components of the C liquid include: 0.1% to 2% NaCl, 0.5% to 0.9% NaCl 2 SO 4 , 0.6%~1%CuSO 4 ,0.2%~2%FeSO 4 , 40% absolute ethanol, and the balance is water.

[0075] The components and mass fractions of the corresponding stable liquid c include: 0.5% to 2% NaCl, 0.2% to 0.8% Na 2 SO 4 , 0.4% ~ 0.8% CuSO 4 ,0.5%~1.5%FeSO 4 , 0.1%~0.2%NaH 2 PO 3 , and the balance is water.

[0076] Adding mass fraction range of 40% absolute ethanol to the precursor liquid C liquid to replace the same mass fraction of water in the precursor liquid B liquid, and then spraying the surface of the weathering steel to promote rusting of the weathering steel surface. Layers dry quickly.

[0077] The color of the rust layer on the surface of the weathering st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com