Regenerated ABS composite material and preparation method thereof

A composite material and raw material technology, applied in the field of recycled ABS composite materials and its preparation, can solve the problems of poor aging resistance of polybutadiene components, no obvious improvement in material color, easy discoloration and yellowing properties, etc. performance, improved recycling value, good stiffness and flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

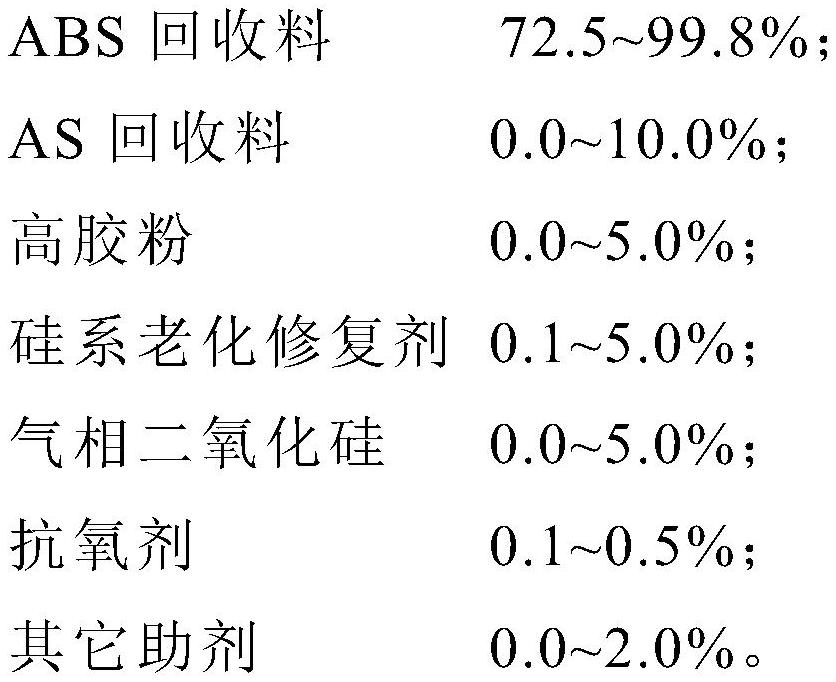

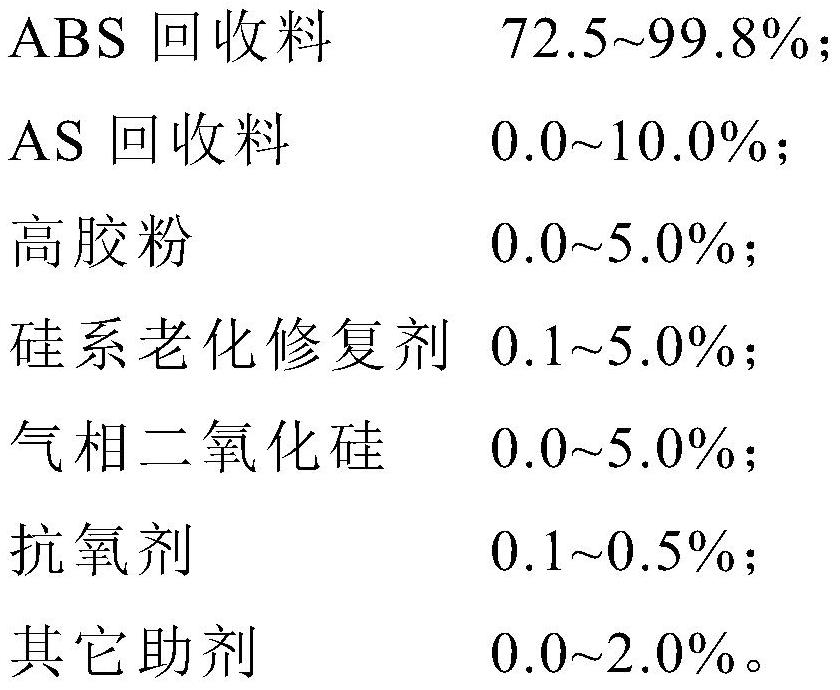

[0032] S1. The following mass percentage of raw materials are prepared: 83.8% ABS recycled material, 10% AS recycled material, 5% high rubber powder, 0.4% silicon-based aging repairing agent, 0.3% antioxidant, 0.5% fumed silica;

[0033] The ABS recycled material is the natural ABS fragments with an average diameter of 10mm prepared by sorting, crushing, cleaning and drying. The ABS recycled material comes from the ABS natural color pipe recycling factory;

[0034] The AS recycled material is pure transparent AS fragments with an average diameter of 12mm prepared by sorting, crushing, cleaning and drying. The AS recycled material comes from the AS drawer recycling factory;

[0035] The high rubber powder is a core-shell polymer of styrene and acrylonitrile-butadiene rubber with a mass ratio of 1:2, and the rubber content is 60%;

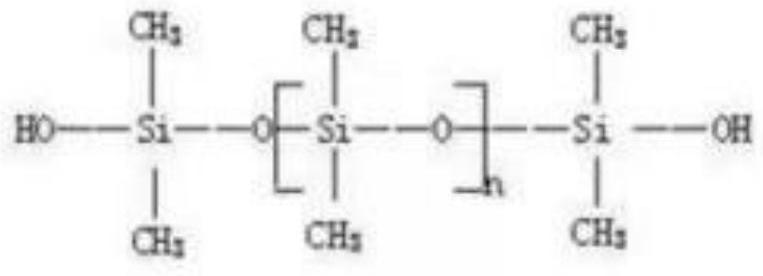

[0036] Silicon-based aging repairing agent is a polysiloxane containing two hydroxyl ends;

[0037] Fumed silica was purchased from Shandong Aochua...

Embodiment 2

[0043] S1. The following mass percentage of raw materials are prepared: 97.5% ABS recycled material, 1% AS recycled material, 1% high rubber powder, 0.1% silicon-based aging repairing agent, 0.3% antioxidant, 0.1% fumed silica;

[0044] The ABS recycled material is the natural ABS fragments with an average diameter of 10mm prepared by sorting, crushing, cleaning and drying. The ABS recycled material comes from the ABS natural color pipe recycling factory;

[0045] The AS recycled material is pure transparent AS fragments with an average diameter of 12mm prepared by sorting, crushing, cleaning and drying. The AS recycled material comes from the AS drawer recycling factory;

[0046] The high rubber powder is a core-shell polymer of styrene and acrylonitrile-butadiene rubber with a mass ratio of 1:2, and the rubber content is 60%;

[0047] Silicon-based aging repairing agent is a polysiloxane containing two hydroxyl ends;

[0048] Fumed silica is fumed silica from Shandong Aochu...

Embodiment 3

[0054] S1. The following mass percentage of raw materials are prepared: 74.7% ABS recycled material, 10% AS recycled material, 5% high rubber powder, 5% silicon-based aging repairing agent, 0.3% antioxidant, 5% fumed silica;

[0055] The ABS recycled material is the natural ABS fragments with an average diameter of 10mm prepared by sorting, crushing, cleaning and drying. The ABS recycled material comes from the ABS natural color pipe recycling factory;

[0056] The AS recycled material is pure transparent AS fragments with an average diameter of 12mm prepared by sorting, crushing, cleaning and drying. The AS recycled material comes from the AS drawer recycling factory;

[0057] The high rubber powder is a core-shell polymer of styrene and acrylonitrile-butadiene rubber with a mass ratio of 1:2, and the rubber content is 60%;

[0058] Silicon-based aging repairing agent is a polysiloxane containing two hydroxyl ends;

[0059] Fumed silica is fumed silica from Shandong Aochuang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com