Built-in continuous oil tube well completion tube column and construction method thereof

A built-in, tubing technology, used in earth-moving drilling, wellbore/well components, sealing/packing, etc., can solve problems such as lack of reliable plugging devices, potential safety hazards, affecting gas well production, etc., and achieve convenient and safe start-up. The effect of reducing wellbore fluid accumulation and prolonging production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

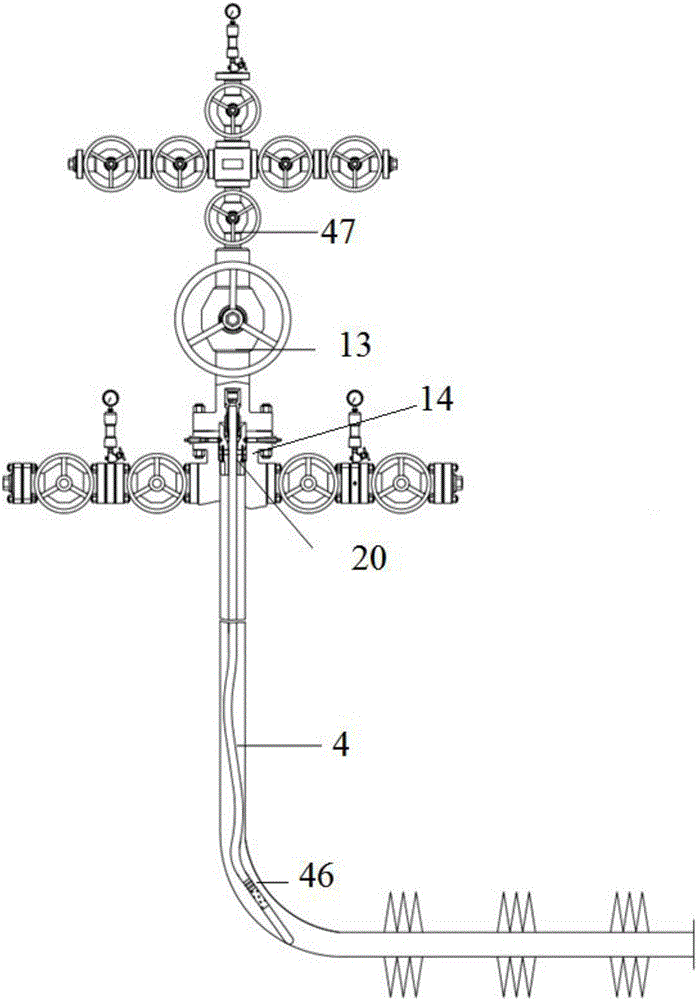

[0044] Such as figure 1 As shown, this embodiment provides a built-in coiled tubing completion production string, which includes a built-in hanger 20, a coiled tubing 4, a plug and a plugging rod, and the upper end of the coiled tubing 4 is connected to the built-in hanger 20 sealing configuration, and hang on the built-in hanger, the built-in hanger is installed in the wellhead tubing head 14, the wellhead No. 1 valve 13 is installed above the wellhead tubing head 14, the bottom of the coiled tubing 4 Connected with the plug, when the string is lowered, the plug plugs the coiled tubing, and the plug is hydraulically opened to realize completion production, and the plug rod is used to cooperate with the plug to plug the coiled tubing for the second time when the completion string is lifted.

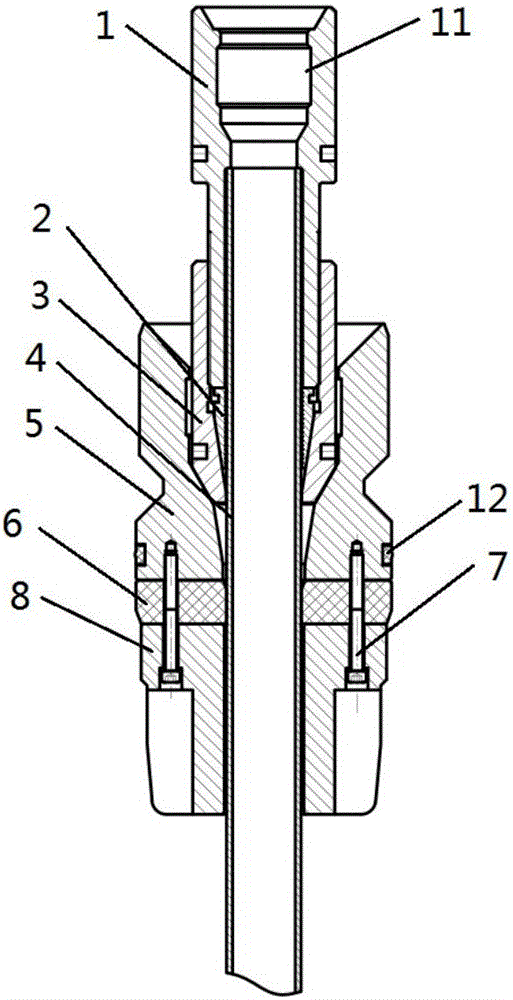

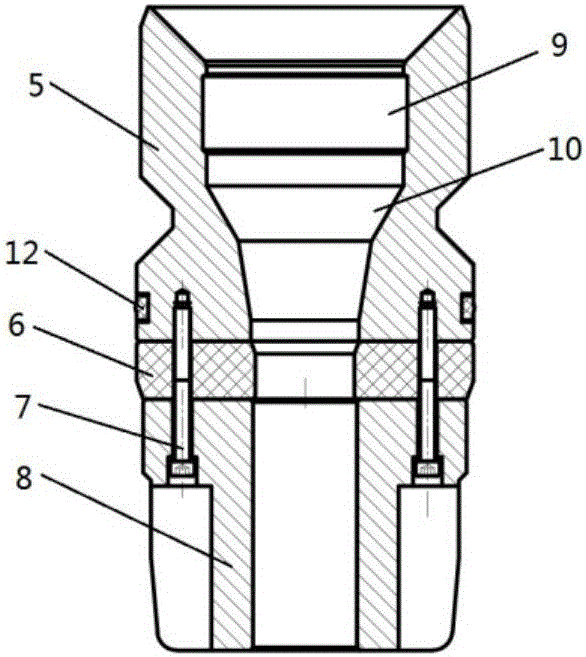

[0045] Such as Figure 2-5 As described above, the built-in hanger includes a lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com