Ground gathering and conveying system for depleted gas storage

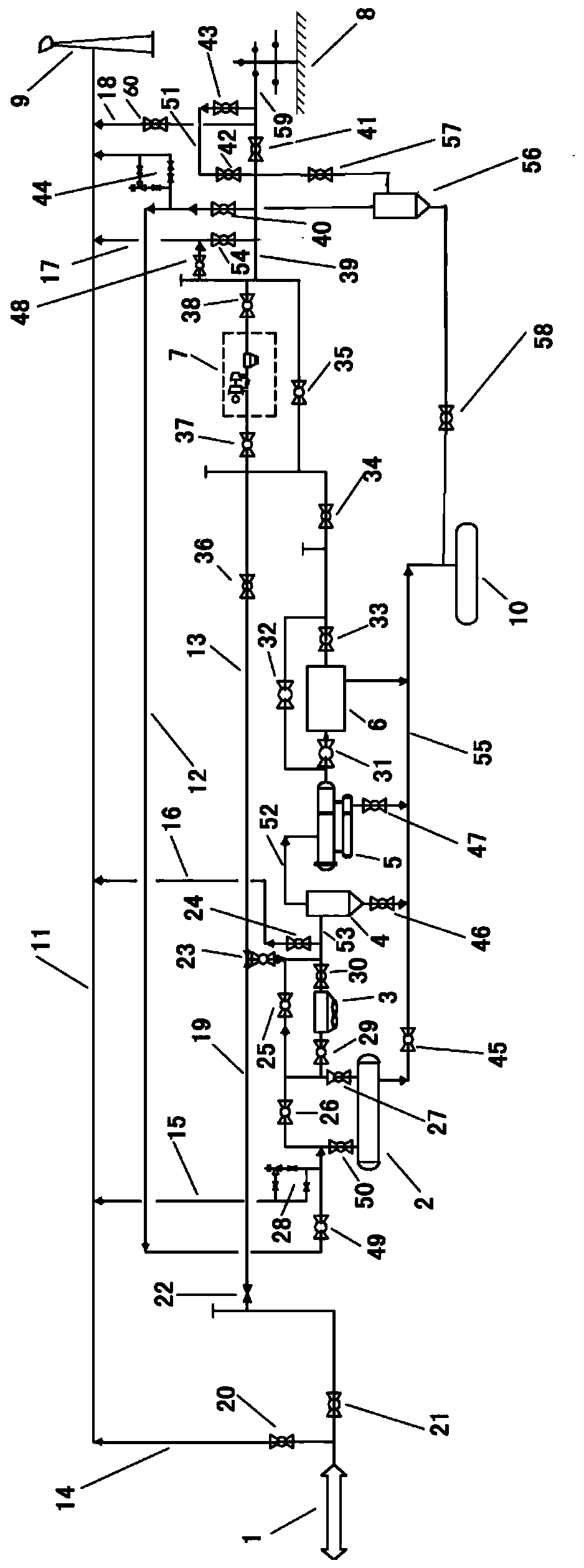

A technology of gathering and transportation system and gas storage, which is applied in the field of ground process flow and equipment to achieve the effects of reducing construction costs, eliminating slug flow, and being easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

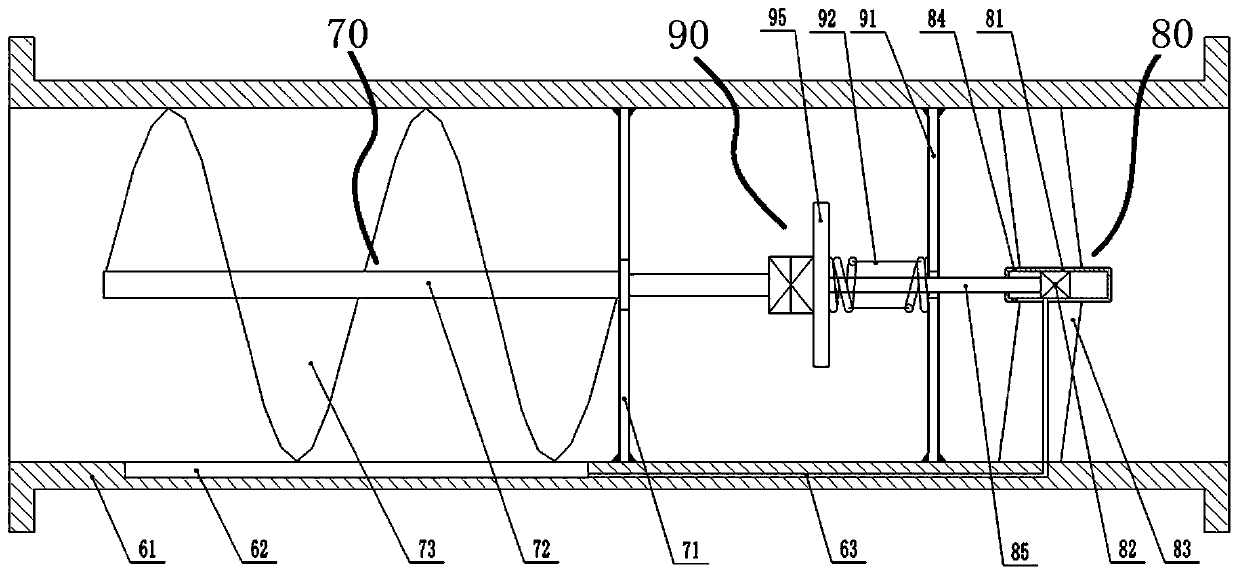

[0073] The pipeline is provided with an effusion controller, and the effusion controller includes a pipe joint 61, which is connected to the pipeline through a flange, and the pipe joint 61 is sequentially provided with a swirl flow generating mechanism 70 from upstream to downstream. , the driving mechanism 90, the spraying mechanism 80, the position corresponding to the swirl flow generating mechanism 70 on the inner wall of the pipe joint 61 is provided with a sump 62, the driving mechanism 90 is connected to the spraying mechanism 80, and the sump 62 is connected to the spraying mechanism through the flow pipe 63 80, the driving mechanism 90 is powered by the swirl generator 70 or natural gas to drive the spraying mechanism 80 to spray the accumulated liquid in the sump 62 into mist and be carried away by the natural gas.

[0074] The swirl mechanism includes a swirl bracket 71 fixedly arranged on the inner wall of the pipe joint 61 , a center shaft 72 is rotated at the cen...

Embodiment 2

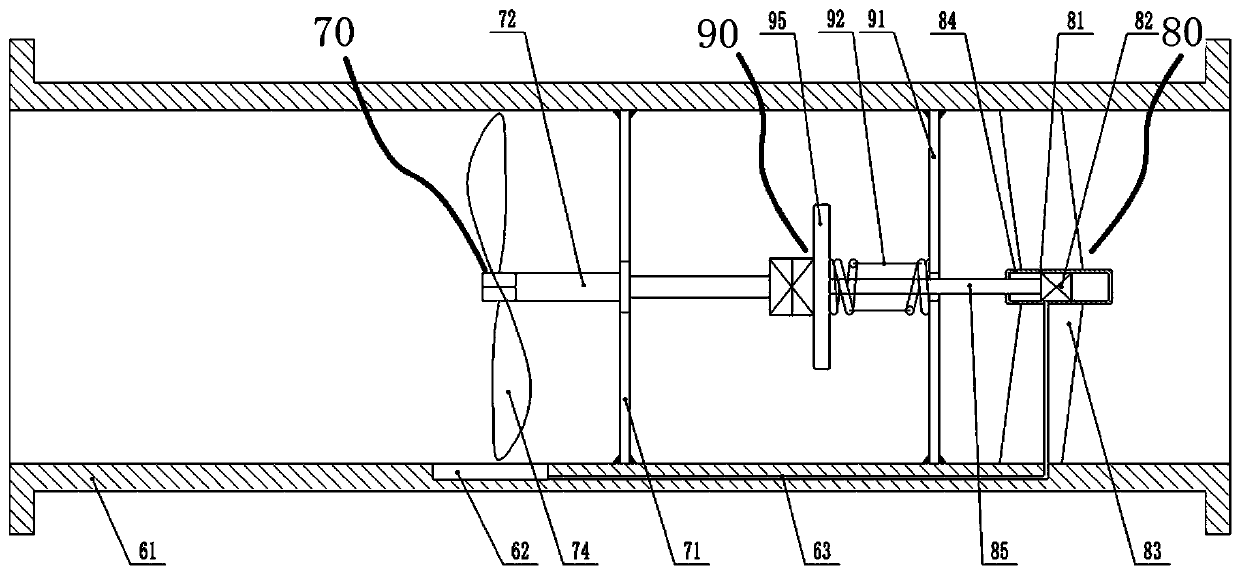

[0079] The difference between this embodiment and Embodiment 1 is that a fan blade 74 is fixedly arranged on the central shaft 72 .

Embodiment 3

[0081] The difference between this embodiment and Embodiment 2 is that the liquid flow pipe 63 is not arranged in the pipe wall of the pipe joint 61 .

[0082] The liquid flow pipe 63 is also communicated with the suppression base liquid tank 66 through the suppression base liquid pipe 64, the suppression base liquid pipe 64 is provided with a one-way valve 65, and the hydrate suppression base liquid in the suppression base liquid tank 66, the hydrate suppression The base fluid is a functionalized dendrimer comprising at least one quaternary ammonium zwitterionic functional end group. The hydrate-inhibiting base fluid needs to be mixed with the effusion, then made into a mist, and then enters the pipeline. The hydrate inhibiting base liquid is mixed and prepared in the liquid flow pipe 63, which makes full use of the accumulated liquid in the pipe, and saves the need to prepare the hydrate inhibiting base liquid and water to make the hydrate inhibitor and then inject it from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com