Vulcanizing equipment

A technology of equipment and vulcanization chamber, applied in the field of vulcanization equipment, can solve the problems of large space occupation, limitation of vulcanization tire processing specifications, unfavorable vulcanization bladder gas circulation, etc., achieve high heating efficiency and improve heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

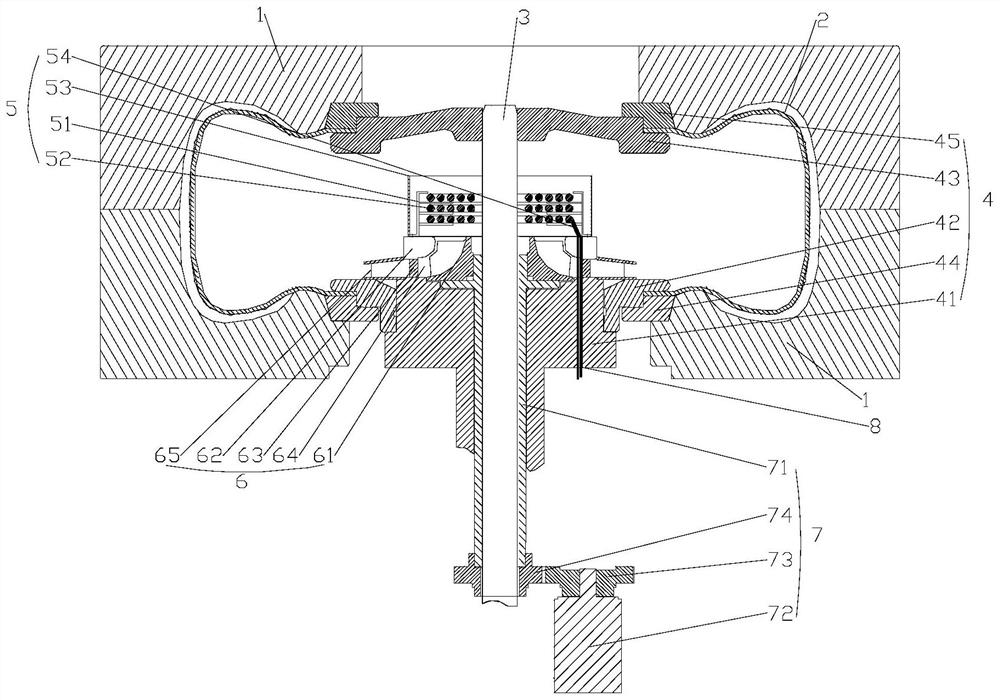

[0086] This embodiment provides a vulcanization equipment, such as Figure 1-Figure 9 As shown, in industrial production, vulcanization equipment is usually used to increase the overall hardness of certain materials. Taking tire vulcanization as an example, tire vulcanization refers to the vulcanization of the outer tire, which is vulcanized by means of model pressure. Before vulcanization, the tire is a plastic rubber with viscoelasticity, which is easy to deform, has low strength, and has no use value. Through vulcanization, the plastic rubber is cured and becomes a highly elastic rubber with useful value.

[0087] The prior art provides a tire vulcanization equipment, such as Figure 11 As shown, a heating component 5 is set in the vulcanization bladder 2 to directly heat the heating medium gas, and a gas circulation component 6 is set in the vulcanization bladder 2 to make the temperature distribution in the vulcanization bladder 2 uniform. However, in the solution provid...

Embodiment 2

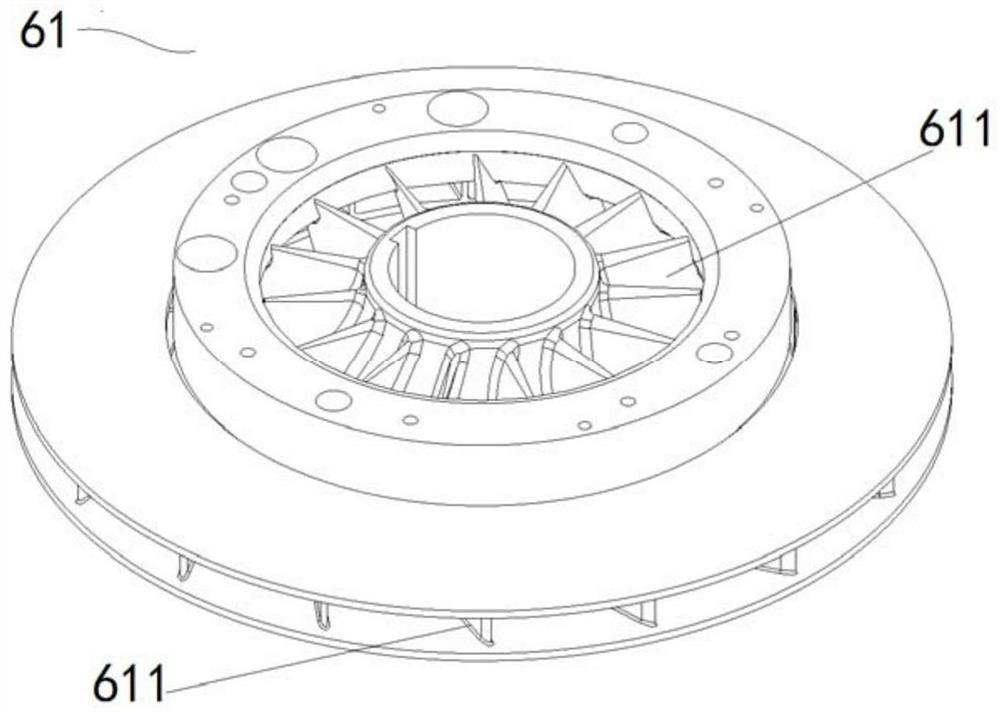

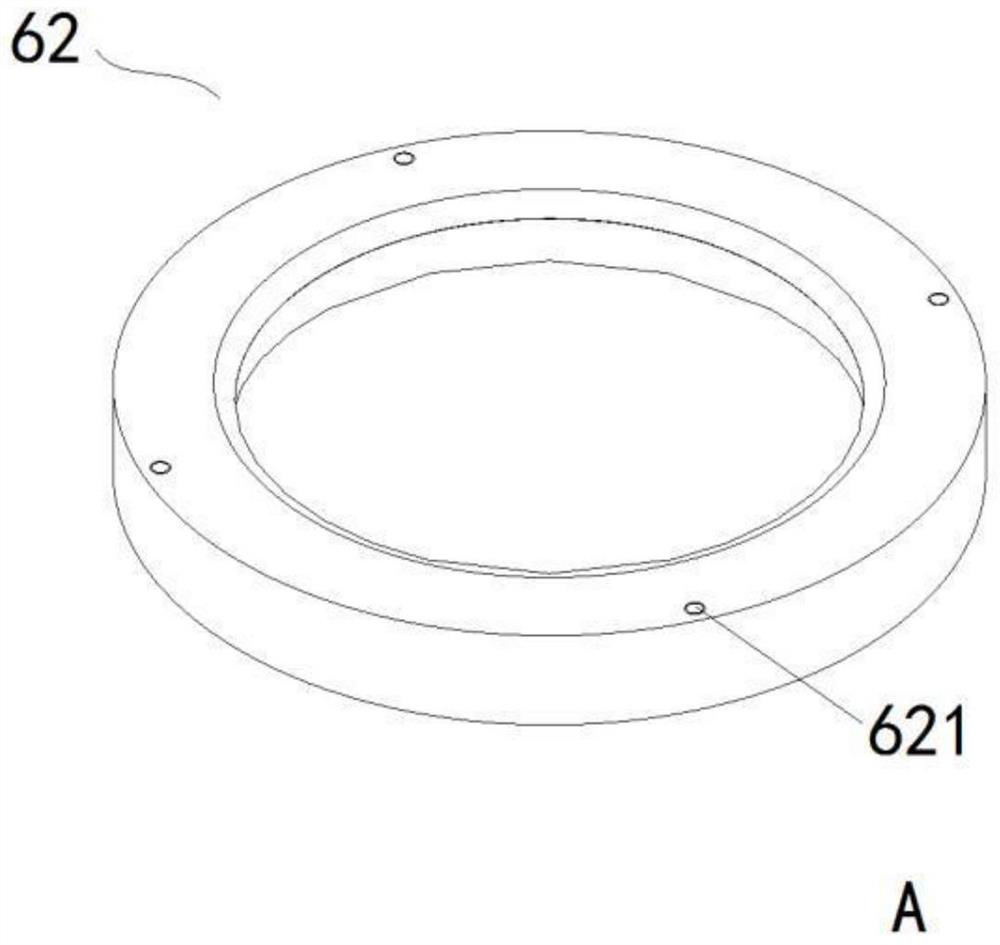

[0135] This embodiment provides a vulcanization equipment, such as Figure 8 As shown, the difference from Embodiment 1 is that the heating assembly 5 and the gas circulation assembly 6 are kept in the vulcanization bladder 2 along the axial layer of the central rod 3, and the positions of the heating assembly 5 and the gas circulation assembly 6 are exchanged, so that the gas circulation assembly 6 is located above the heating assembly 5 .

[0136] Specifically, the heating assembly 5 is set on the ring seat 41, and the rotating shaft sleeve 71 is extended along the central rod 3 to the depth of the vulcanization bladder 2, so that the air outlet 61 of the gas circulation assembly 6 is located above the heating assembly 5, and the ring The position of the seat 41 corresponding to the lower part of the heating assembly 5 is set in a conical shape of flow guide, which is convenient to guide the heating medium gas.

[0137] Further, as Figure 9 Shown is a schematic diagram of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com