Efficient heat exchange tube and evaporative condenser

A technology for evaporative condensers and heat exchange tubes, applied in evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of low heat transfer coefficient and large wind resistance outside the tube, and achieve high heat transfer coefficient, Enhanced heat transfer performance and excellent heat resistance and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

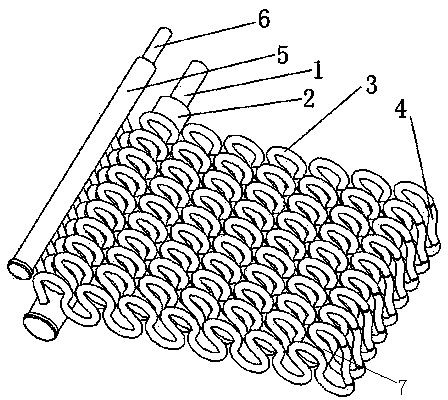

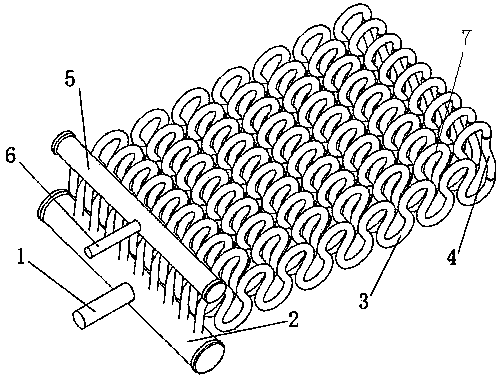

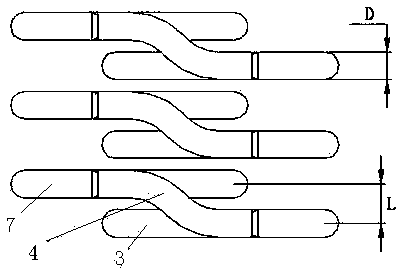

[0035] Such as figure 1 As shown, a high-efficiency heat exchange tube includes a gas collection pipe 2 and a liquid collection pipe 5, and several heat exchange tube units are communicated between the gas collection pipe 2 and the liquid collection pipe 5, and the heat exchange tube unit includes the first A heat exchange tube 3, a second heat exchange tube 7 and a corner elbow 4, the inlet of the first heat exchange tube 3 communicates with the collector 2, the outlet of the second heat exchange tube 7 communicates with the collector The liquid pipes 5 are connected, and the second heat exchange pipes 7 are arranged in layers and staggered up and down relative to the first heat exchange pipes 3, and the corner elbow 4 is arranged between the first heat exchange pipes 3 and the first heat exchange pipes 3. Between the second heat exchange tubes 7 , the outlet of the first heat exchange tube 3 is communicated with the inlet of the second heat exchange tube 7 . The setting of ...

Embodiment 2

[0040] An evaporative condenser includes a box body, a heat exchange coil, a fan, a water collecting pan, a circulating water pump and a spraying device, and the evaporative condenser includes the high-efficiency heat exchange tubes described above. The evaporative condenser involved in the present invention mainly adopts the above-mentioned high-efficiency heat exchange tubes with better thermal conductivity and smaller tube diameters.

[0041] In the evaporative condenser of the present invention, the refrigerant enters the gas collecting pipe 2 from the inlet connecting pipe 1, and flows through the "Ω" twisted heat exchange tube, and the diameter of the heat exchange tube is φ≤15mm. In this embodiment, , the heat exchange tubes include the first heat exchange tube 3 of upper and lower layers, the second heat exchange tube 7 and the corner elbow 4, the first heat exchange tube 3 and the second heat exchange tube The shape, size and arrangement of the heat pipes 7 are consis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com