Toughening material of composite material and preparation method toughening material

A composite material and toughening technology, which is applied in the direction of textiles, papermaking, non-woven fabrics, etc., can solve the problems that cannot meet the requirements of large-scale engineering applications, the difficulty of RTM composite material forming process, and the low production efficiency of electrospinning process, etc. problem, to achieve the effect of improved compressive strength, improved yield and quality stability, and small fiber diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

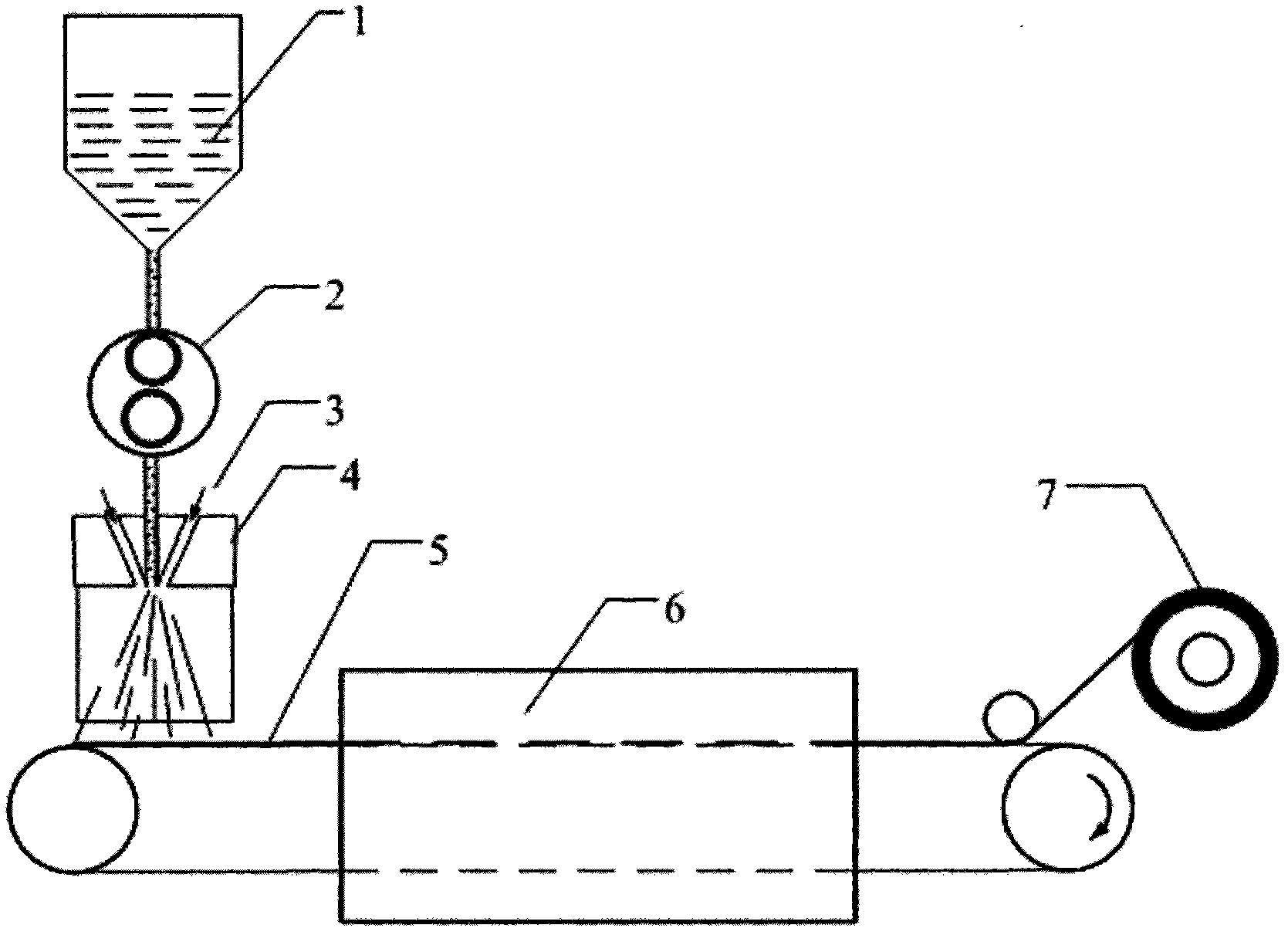

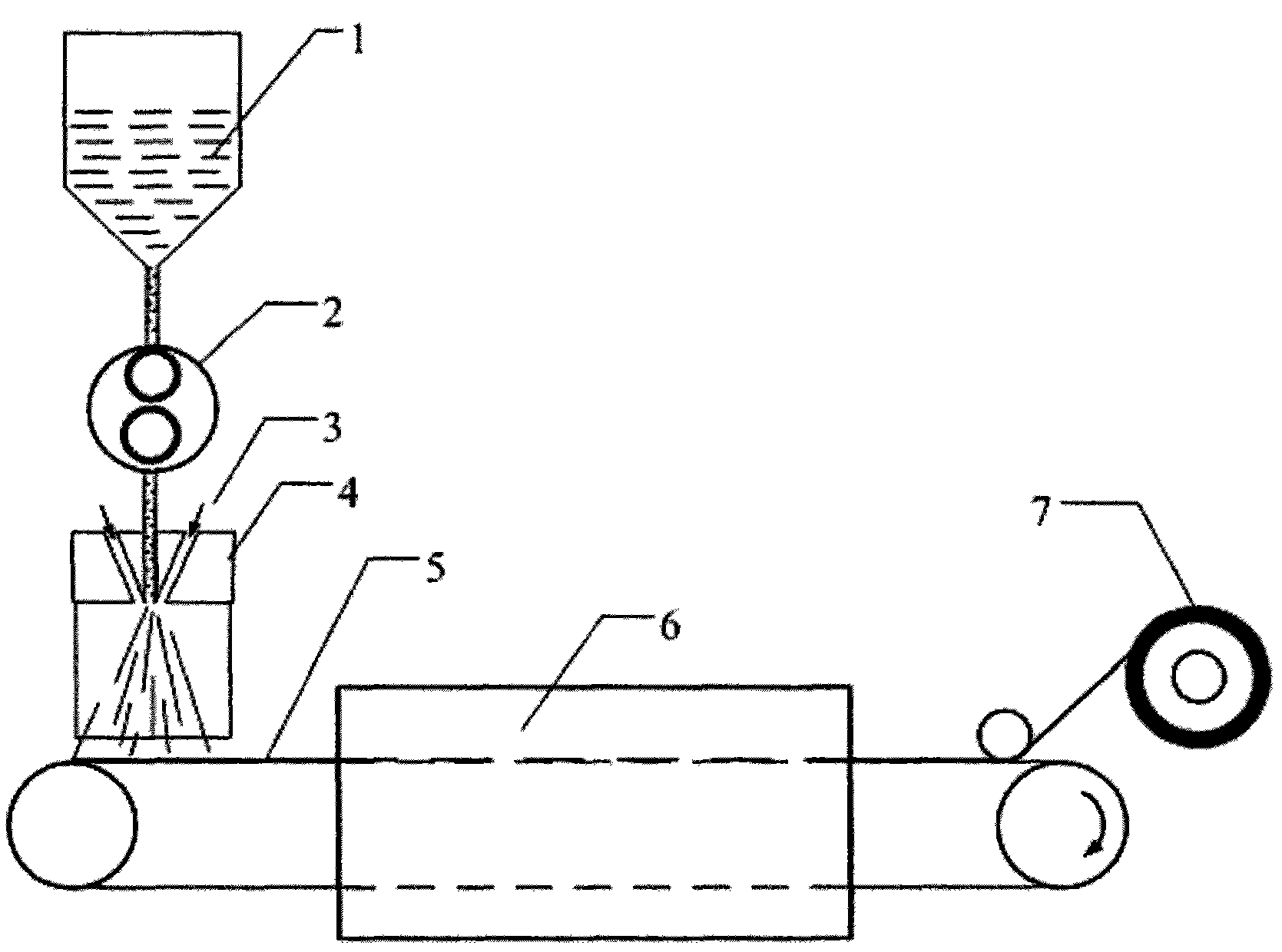

[0015] The method for preparing the toughened material of the above-mentioned high-performance composite material is characterized in that the steps of preparation are as follows:

[0016] 1. Preparation of spinning solution: Add thermoplastic polymer into a container of appropriate volume, and add corresponding organic solvent, stir to dissolve the polymer in the solvent, and form a polymer spinning solution with a concentration of 5% to 50%;

[0017] 2. The solution is sprayed for spinning; the spinning solution is added to the storage tank of the melt-blown spinning equipment, and the spinning solution is quantitatively transported to the spinning assembly of the spinning equipment through a metering pump and extruded through the spinneret hole. The spinning liquid in the spinneret hole is stretched under the airflow of 1MPa~8MPa compressed air to form ultrafine fibers; its solution-blown spinning device includes a spinning assembly and a fiber receiving device, and the spin...

Embodiment 1

[0024] Dissolve 10g of polysulfone in 90g of ethylene dichloride to prepare a spinning solution with a concentration of 10%, and then form polysulfone ultrafine fibers under the extrusion of 0.2MPa compressed air and air stretching in the solution-blown spinning equipment , and deposited on the deposition device of the spinning equipment to form a superfine fiber nonwoven fabric. The prepared microfiber nonwoven fabric toughened 3234 / T300-40B epoxy resin-based carbon fiber composite material, and its compressive strength after impact was increased from 170MPa to 312MPa.

Embodiment 2

[0026] 15g phenolphthalein-modified polyether ketone is dissolved in 85g tetrahydrofuran, is prepared into the spinning solution of 15% concentration, then forms phenolphthalein-modified polyether ketone under the extruding of 0.5MPa compressed air and airflow stretching in solution blown spinning equipment. Etherketone ultrafine fibers are deposited on the deposition device of the spinning equipment to form ultrafine fiber nonwovens. The prepared microfiber nonwoven fabric toughened 5228A / T300-40B epoxy resin-based carbon fiber composite material, and its compressive strength after impact was increased from 220MPa to 348MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com