Novel ship tail gas treatment system

A technology for ship exhaust and treatment systems, which is applied in the fields of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve problems such as the inability of engine exhaust emissions, and achieves reduction of greenhouse gas effects, volume reduction, and uniform diffusion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

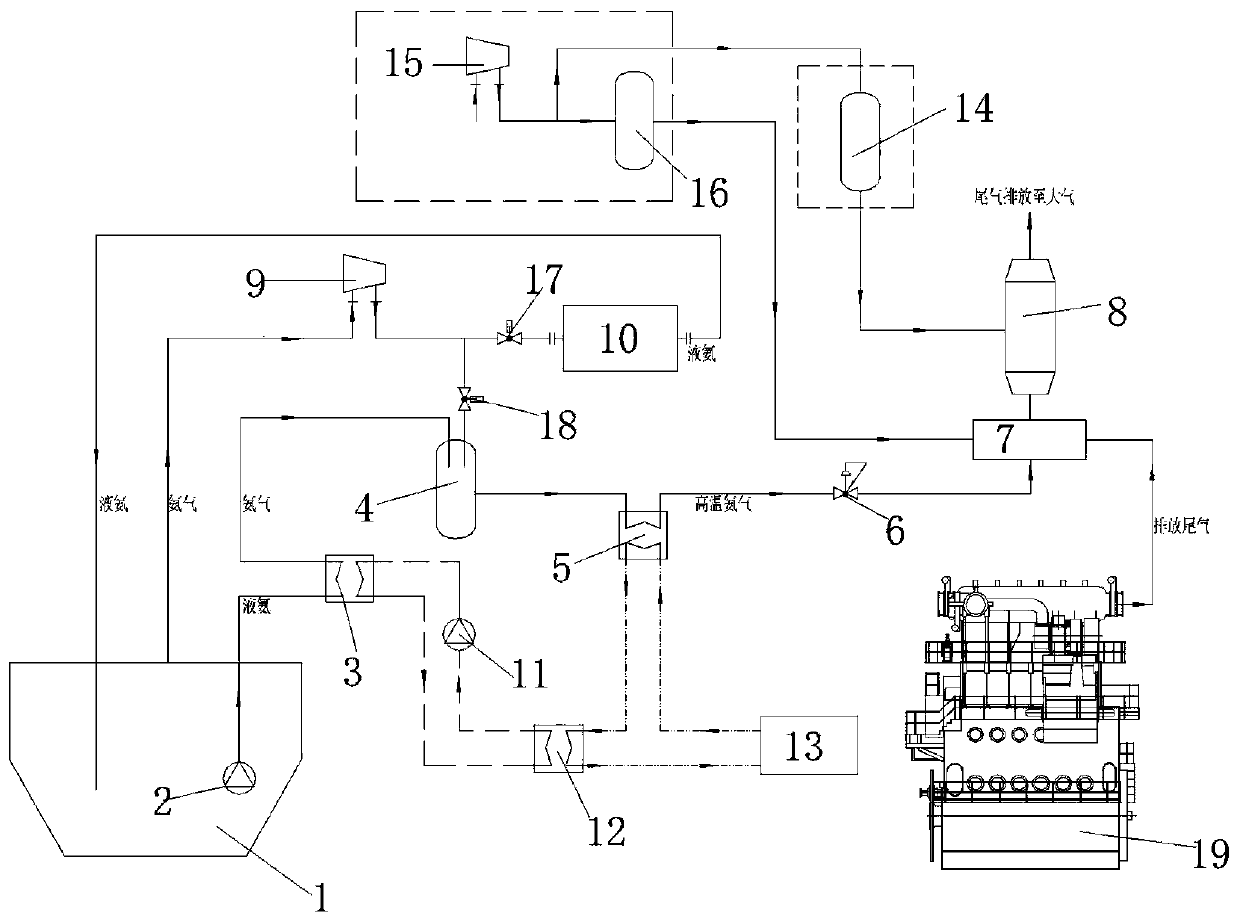

[0027] Such as figure 2As shown, when there is too much volatilized ammonia in the liquid ammonia fuel storage tank and the tail gas treatment requires less ammonia, open the first valve and the second valve to run the ammonia liquefaction system. The liquid ammonia low-pressure pump does not work, and the volatilized ammonia gas in the liquid ammonia fuel storage tank enters the ammonia gas compressor for compression. After compression, part of the ammonia gas enters the ammonia gas buffer tank through the second valve, and the other part of the ammonia gas enters through the first valve. Ammonia liquefaction device, liquefied to form liquid ammonia, and returned to the liquid ammonia fuel storage tank.

[0028] The compressed ammonia gas enters the ammonia gas buffer tank for buffering, and then enters the ammonia gas heater to be heated to form high-temperature ammonia gas. After the control system controls the flow regulating valve to adjust the flow of ammonia gas, it is...

Embodiment 2

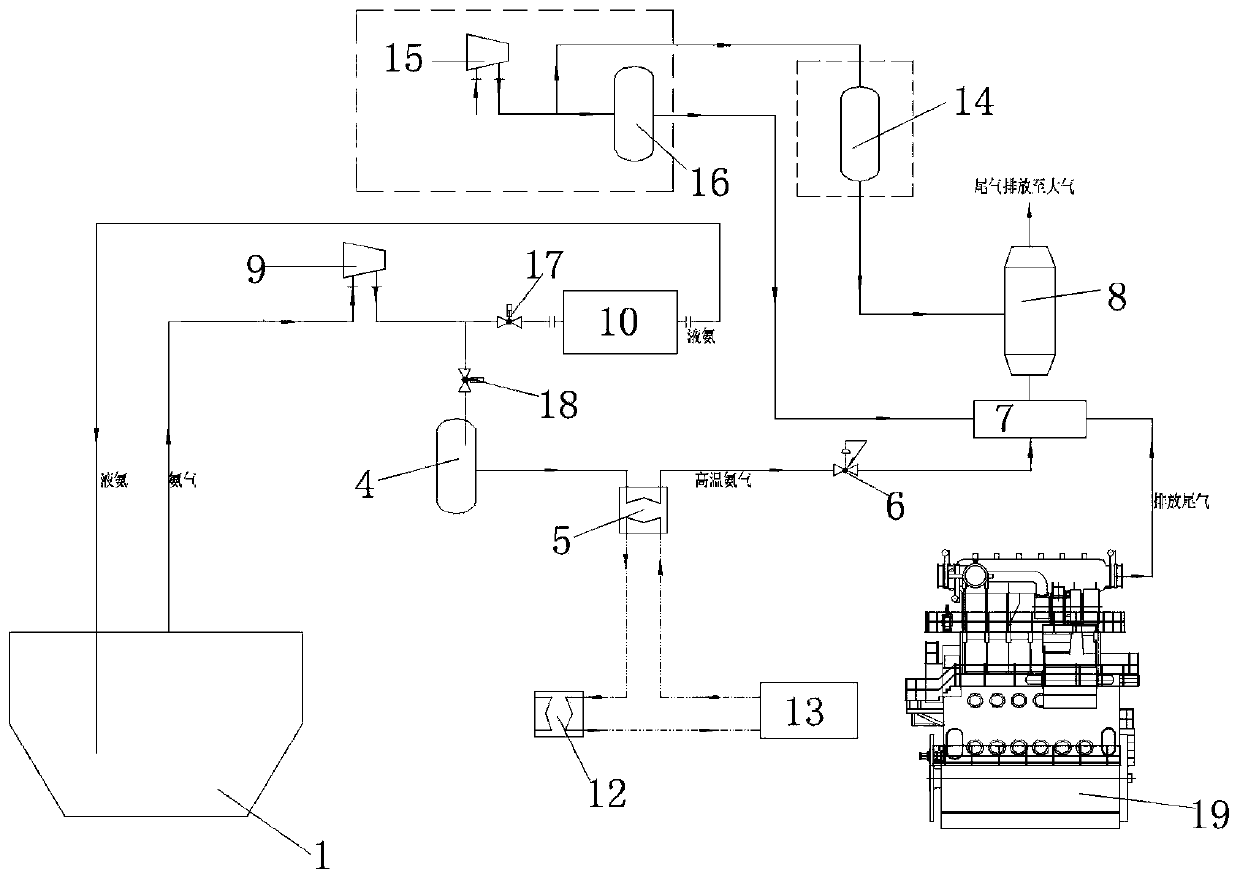

[0032] Such as image 3 As shown, when the volatilized ammonia gas in the liquid ammonia fuel storage tank is basically equal to the amount of ammonia gas required for tail gas treatment, the second valve is opened, the first valve is closed, and the ammonia liquefaction system is stopped. The liquid ammonia low-pressure pump does not work, and the volatilized ammonia gas in the liquid ammonia fuel storage tank enters the ammonia gas compressor for compression. After compression, part of the ammonia gas enters the ammonia gas buffer tank through the second valve, and the other part of the ammonia gas enters through the first valve. Ammonia liquefaction device, liquefied to form liquid ammonia, and returned to the liquid ammonia fuel storage tank.

[0033] The compressed ammonia gas enters the ammonia gas buffer tank for buffering, and then enters the ammonia gas heater to be heated to form high-temperature ammonia gas. After the control system controls the flow regulating valv...

Embodiment 3

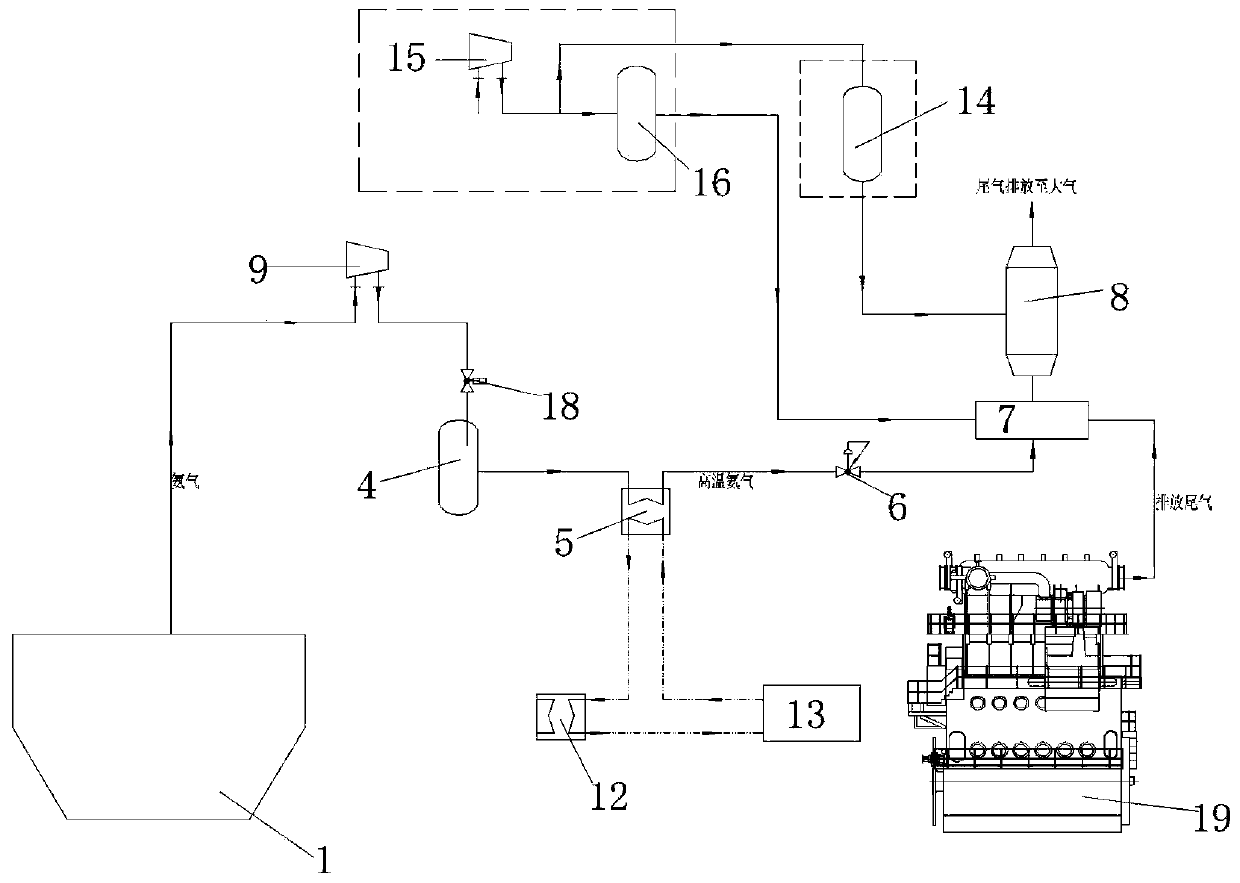

[0036] Such as Figure 4 As shown, when there is too little volatilized ammonia in the liquid ammonia fuel storage tank and the amount of ammonia required for tail gas treatment is too much, the second valve is opened, and the ammonia liquefaction system does not operate. There is low-temperature liquid ammonia (-33.6°C) stored in the liquid ammonia fuel storage tank, and the liquid ammonia low-pressure pump pressurizes the liquid ammonia in the liquid ammonia fuel storage tank to 18bar, and the liquid ammonia in the liquid ammonia fuel storage tank is supplied by the liquid ammonia low-pressure pump It is pumped out and evaporated in the liquid ammonia evaporator to form low-temperature ammonia gas. The low-temperature ammonia gas enters the ammonia gas buffer tank for buffering, and then enters the ammonia gas heater to be heated to form high-temperature ammonia gas. The ammonia gas is adjusted by the control system to control the flow regulating valve. After the flow rate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com