Turbine blade tailing edge curved type exhaust crack structure

A turbine blade and trailing edge technology, applied in the directions of blade support elements, engine elements, machines/engines, etc., can solve the problems of blade structural strength damage, large flow resistance, low cooling effect, etc., to improve efficiency and reduce flow Resistance and loss, the effect of reducing cold air flow resistance and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

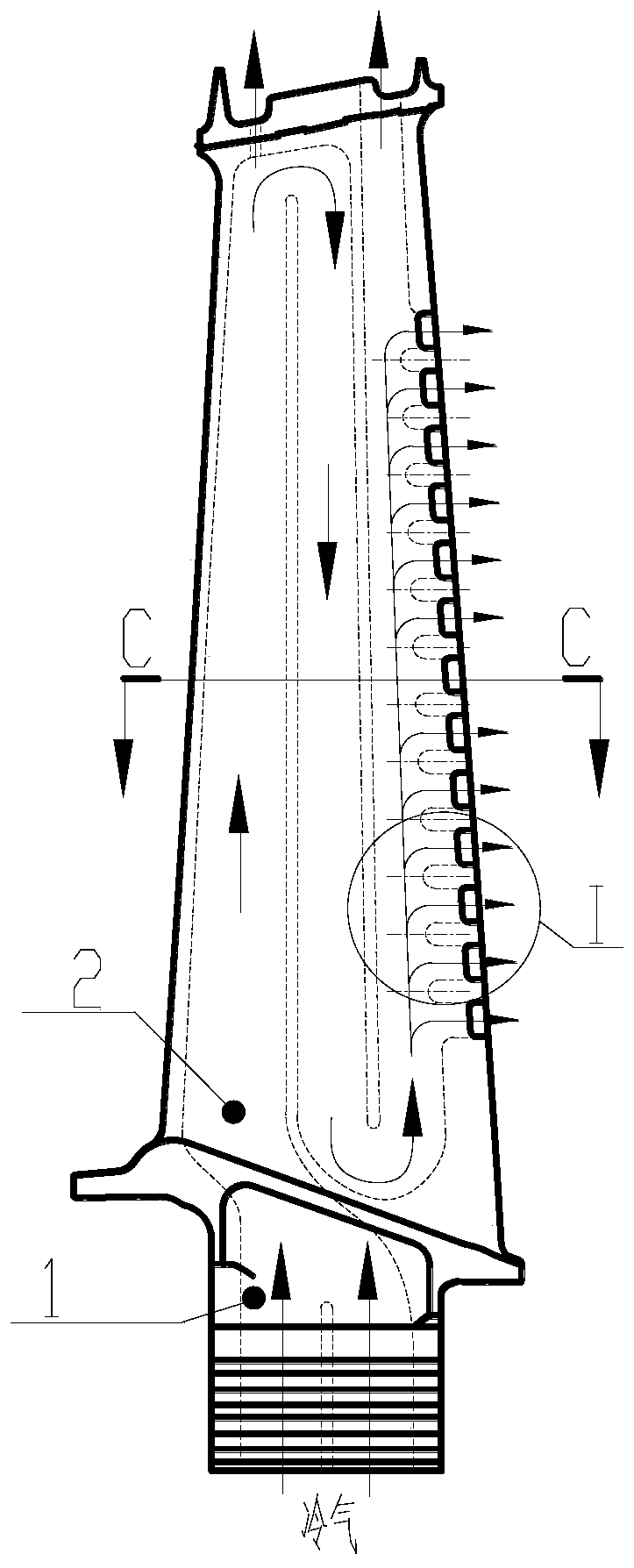

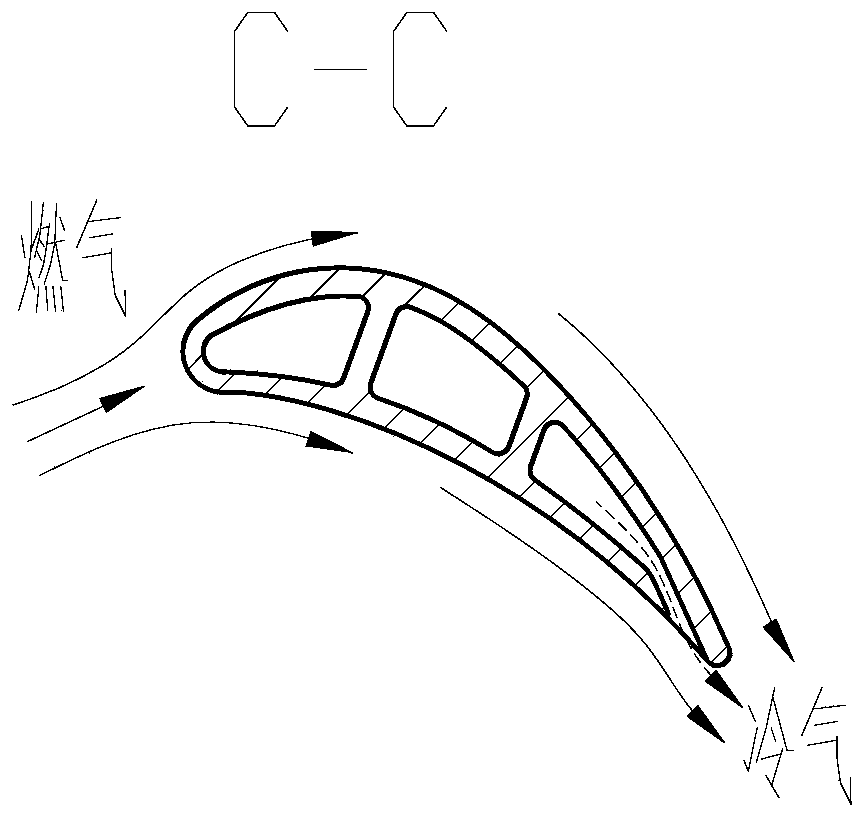

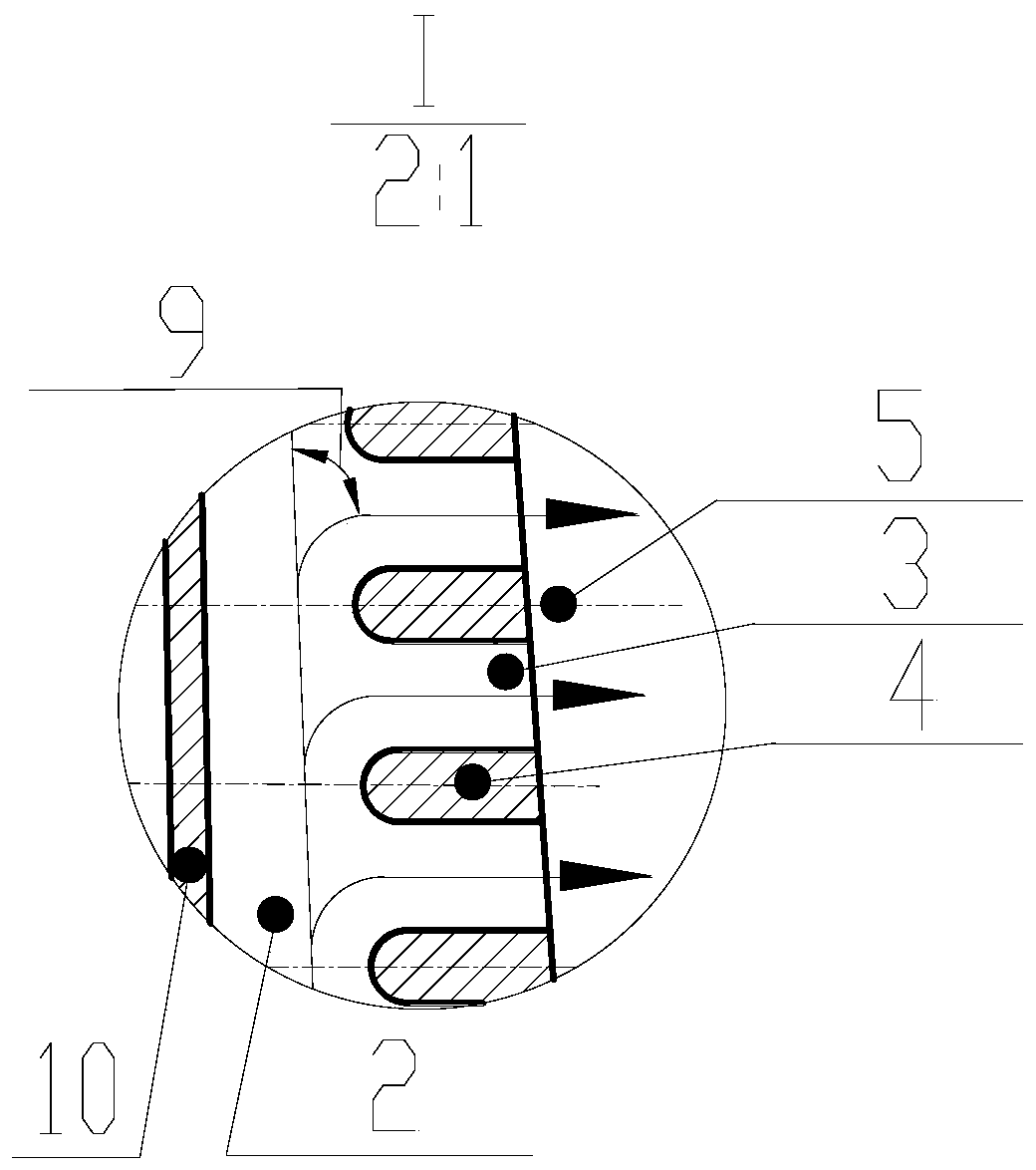

[0036] Please refer to Figure 2. A turbine blade trailing edge curved exhaust splitting structure, comprising a hollow turbine blade 1, an inner cavity cold air channel 2, a trailing edge exhaust splitting channel 3 and a trailing edge splitting rib 4;

[0037] The hollow turbine blade 1 is provided with an inner cavity cold air channel 2 for low-temperature cooling gas to flow inside the blade to cool the blade. The trailing edge of the hollow turbine blade 1 is provided with trailing edge slit ribs 4 arranged side by side, and a trailing edge exhaust slit channel 3 is formed between the trailing edge slit ribs 4 arranged side by side, for the cooling air to discharge the blade, and at the same time The trailing edge of the blade is cooled by film blanket. In addition to increasing the internal heat exchange area of the blade, the structure of the split rib 4 at the trailing edge also guides the cooling air in the inner cavity of the blade so that its flow direction turns....

Embodiment 2

[0040] Please refer to Figure 2. A turbine blade trailing edge curved exhaust splitting structure, comprising a hollow turbine blade 1, an inner cavity cold air channel 2, a trailing edge exhaust splitting channel 3 and a trailing edge splitting rib 4;

[0041] The structural shape of the split rib 4 at the trailing edge is controlled by the center line 5 of the rib. The center line 5 of the rib is an arc or a spline curve, and the split rib 4 at the trailing edge forms an arc or a spline curve. The width of the split rib 4 at the trailing edge is symmetrically distributed along the center line 5 of the rib. The angles between the tangent direction and the horizontal plane of the trailing edge exhaust slit centerline 6 at the cold air inlet and outlet ends of the hollow turbine blade 1 are the incident angle ∠A1 and the outgoing angle ∠A2, and ∠A1>∠A2. Typical values are ∠A1 = 15° and ∠A2 = 0°, at this time, the air-conditioning turning angle ∠A is about 75°.

Embodiment 3

[0043] Please refer to Figure 2. A turbine blade trailing edge curved exhaust splitting structure, comprising a hollow turbine blade 1, an inner cavity cold air channel 2, a trailing edge exhaust splitting channel 3 and a trailing edge splitting rib 4;

[0044] The structural shape of the split rib 4 at the trailing edge is controlled by the center line 5 of the rib. The center line 5 of the rib is an arc or a spline curve, and the split rib 4 at the trailing edge forms an arc or a spline curve. The width of the split rib 4 at the trailing edge is symmetrically distributed along the center line 5 of the rib. The angles between the tangent direction and the horizontal plane of the trailing edge exhaust slit centerline 6 at the cold air inlet and outlet ends of the hollow turbine blade 1 are the incident angle ∠A1 and the outgoing angle ∠A2, and ∠A1>∠A2. Typical values can be ∠A1=25° and ∠A2=15°, and the turning angle of the cold air ∠A is about 65°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com