Flue gas recirculation boiler structure of combustor

A flue gas recirculation and burner technology, applied in combustion methods, combustion types, combustion equipment, etc., can solve problems such as affecting normal operation, reducing thermal efficiency by 1% to 2.5%, and destructive consequences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

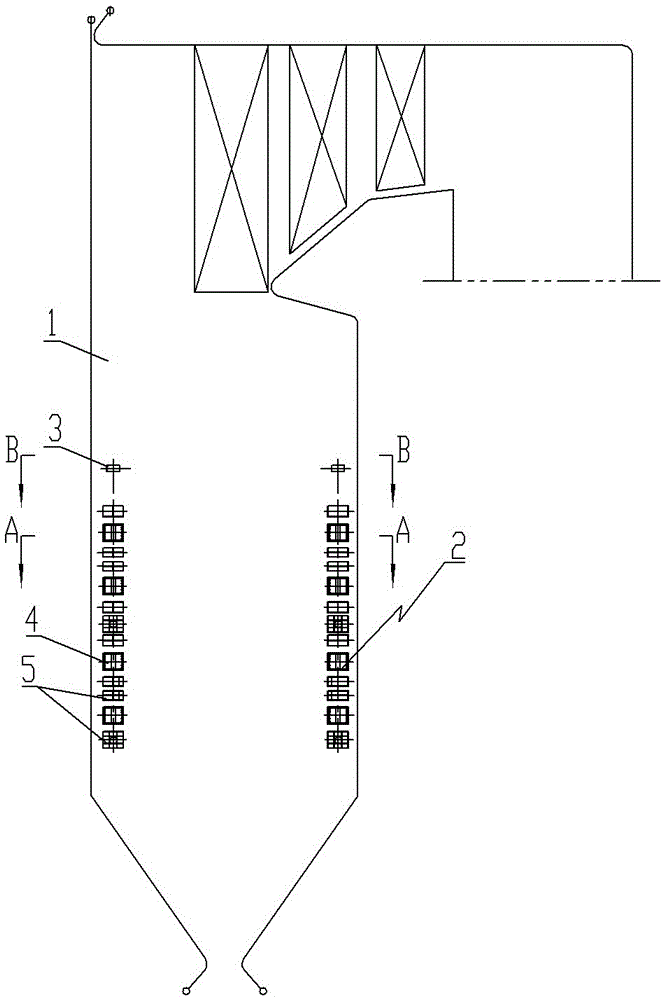

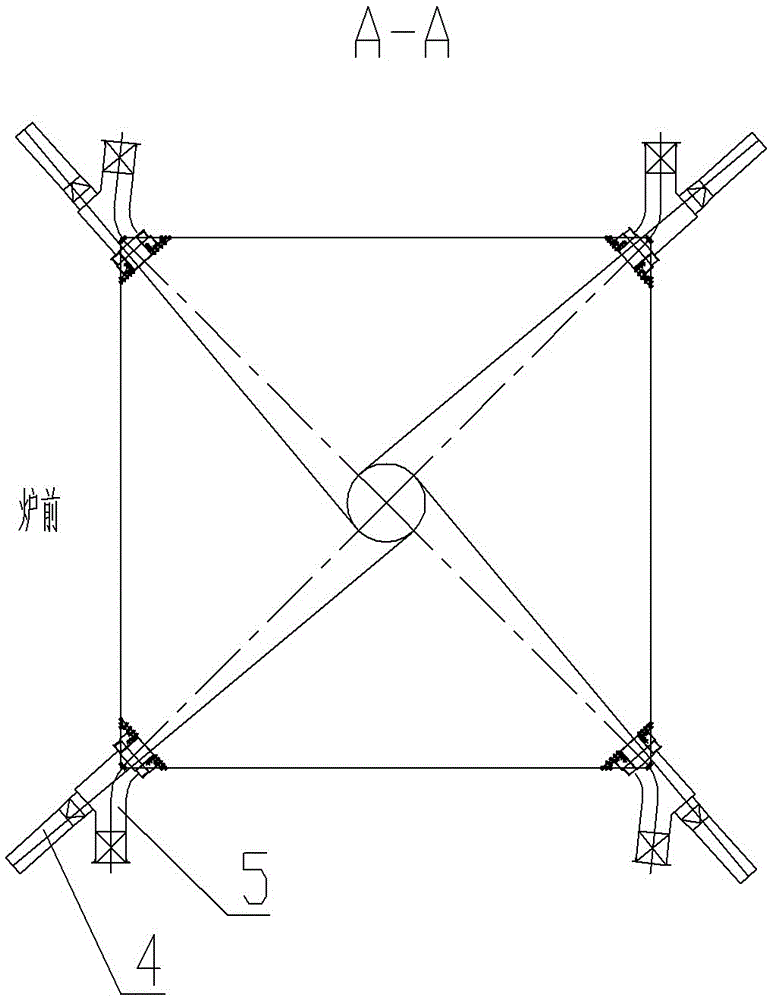

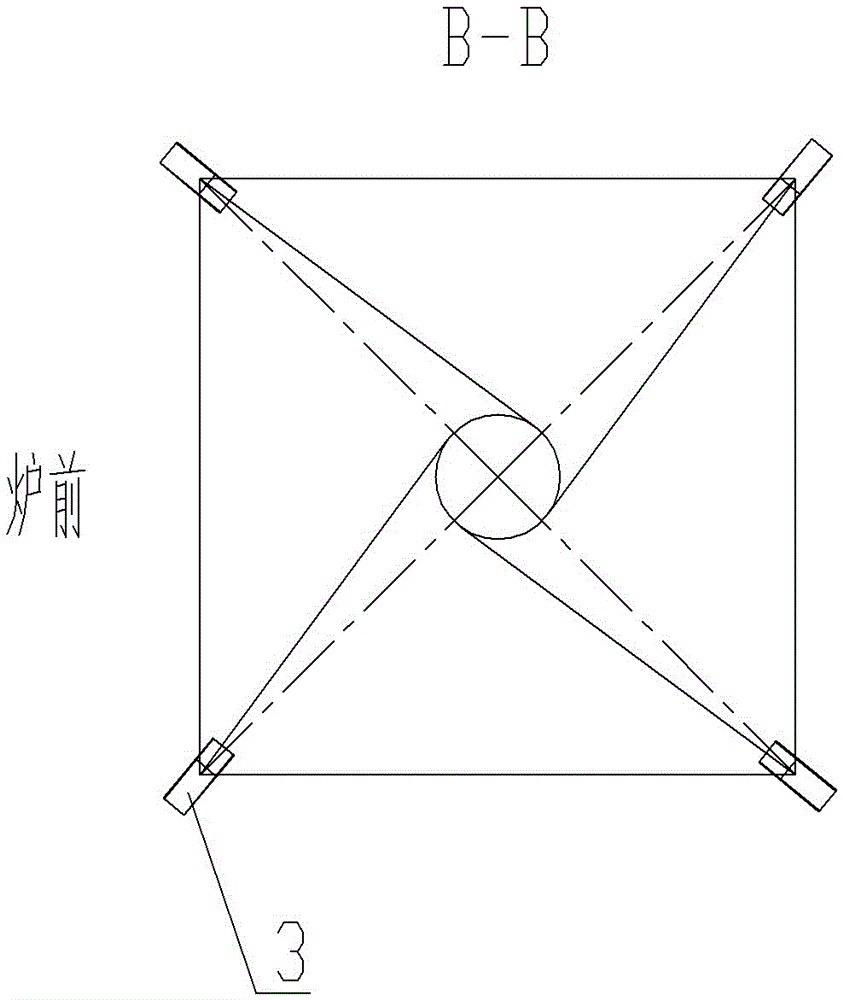

[0011] See figure 1 , figure 2 , image 3 As shown, a burner flue gas recirculation boiler structure includes a furnace 1, a main burner 2 is installed on the furnace 1, the main burner 2 includes a primary air interface 4 and a secondary air interface 5, the primary air interface 4 and The air outlet direction of the secondary air interface 5 is tangent to the tangent circle of the main burner 2, and a flue gas recirculation nozzle 3 is arranged above the main burner 2. The flue gas recirculation nozzle 3 includes four, four The air outlet directions of the flue gas recirculation nozzles 3 are respectively tangent to the tangent circle of the main burner 3 . There are four groups of primary air interfaces 4 arranged from bottom to top, and a group of secondary air interfaces 5 are arranged at the upper and lower ends of each group of primary air interfaces 4, and each group of primary air interfaces 4 and secondary air interfaces 5 includes four uniformly arranged indivua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com