Waste velvet classification treatment and recovery device for garment processing factory

A recycling device, processing plant technology, applied in the direction of manufacturing tools, separation methods, transportation and packaging, etc., can solve the problems of reduced space utilization, large storage space, large bulkiness rate, etc., to improve the safety and life of use, improve stability The effect of improving the falling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

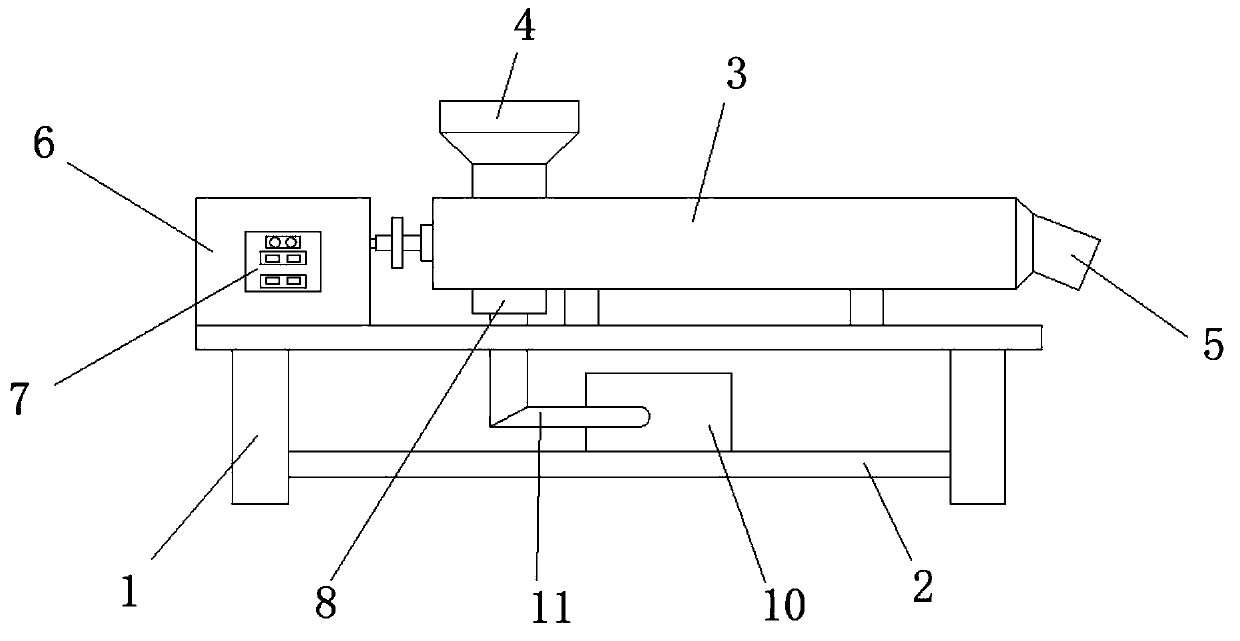

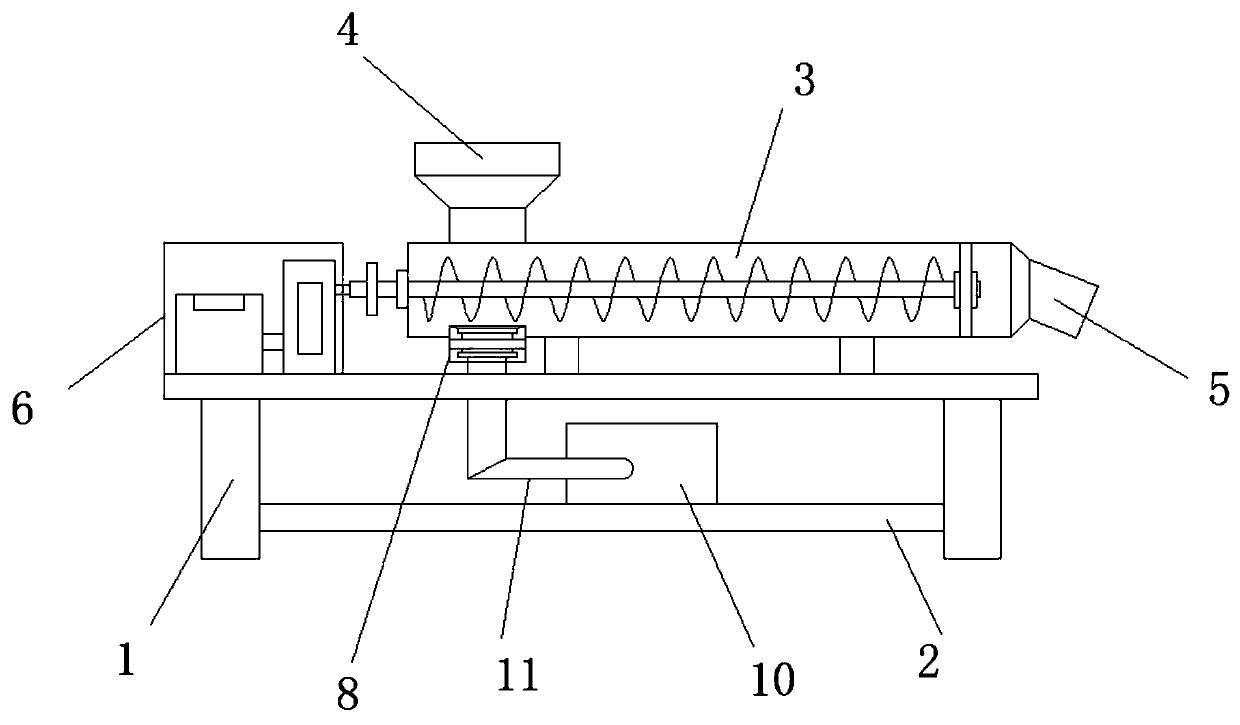

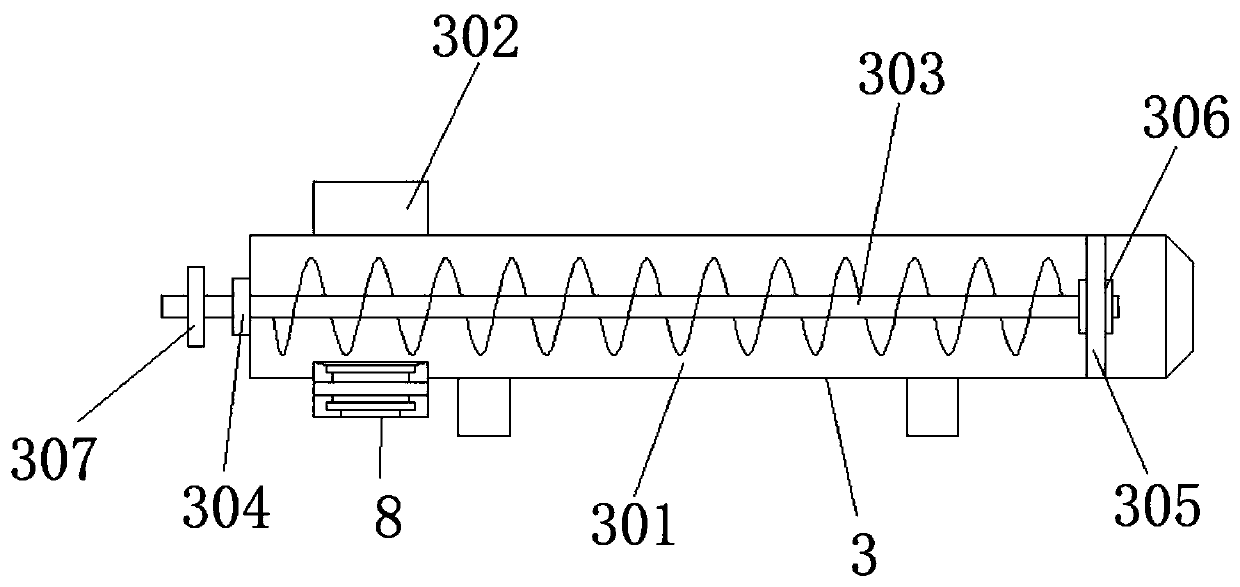

[0029] Such as Figure 1-8 As shown, the present invention provides a technical solution: a waste cashmere sorting and recycling device for garment processing factories, including a frame 1, a pallet 2, an extrusion mechanism 3, a collecting hopper 4, a discharge pipe 5, and a driving mechanism 6 and a control mechanism 7, a supporting plate 2 is installed at the bottom of the inner cavity of the frame 1, the extruding mechanism 3 is arranged on the top surface of the frame 1, and the collecting hopper 4 is arranged on one side of the top surface of the extruding mechanism 3, so The discharge pipe 5 is arranged at the output end of the extruding mechanism 3 , the driving mechanism 6 is arranged on the left side of the extruding mechanism 3 , and a control mechanism 7 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com