Method for processing monohydrallite ore washing gangue

A bauxite and ore washing technology, which is applied in the field of bauxite washing tailings processing, can solve the problems of high concentration and sedimentation speed, difficult tailings treatment, unfavorable water resource recovery, etc., to achieve improved efficiency and low cost , to achieve the effect of flocculation and sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

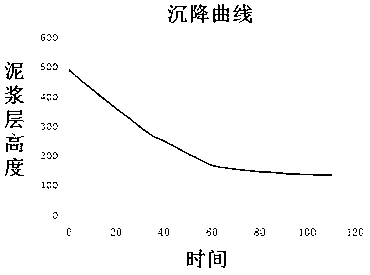

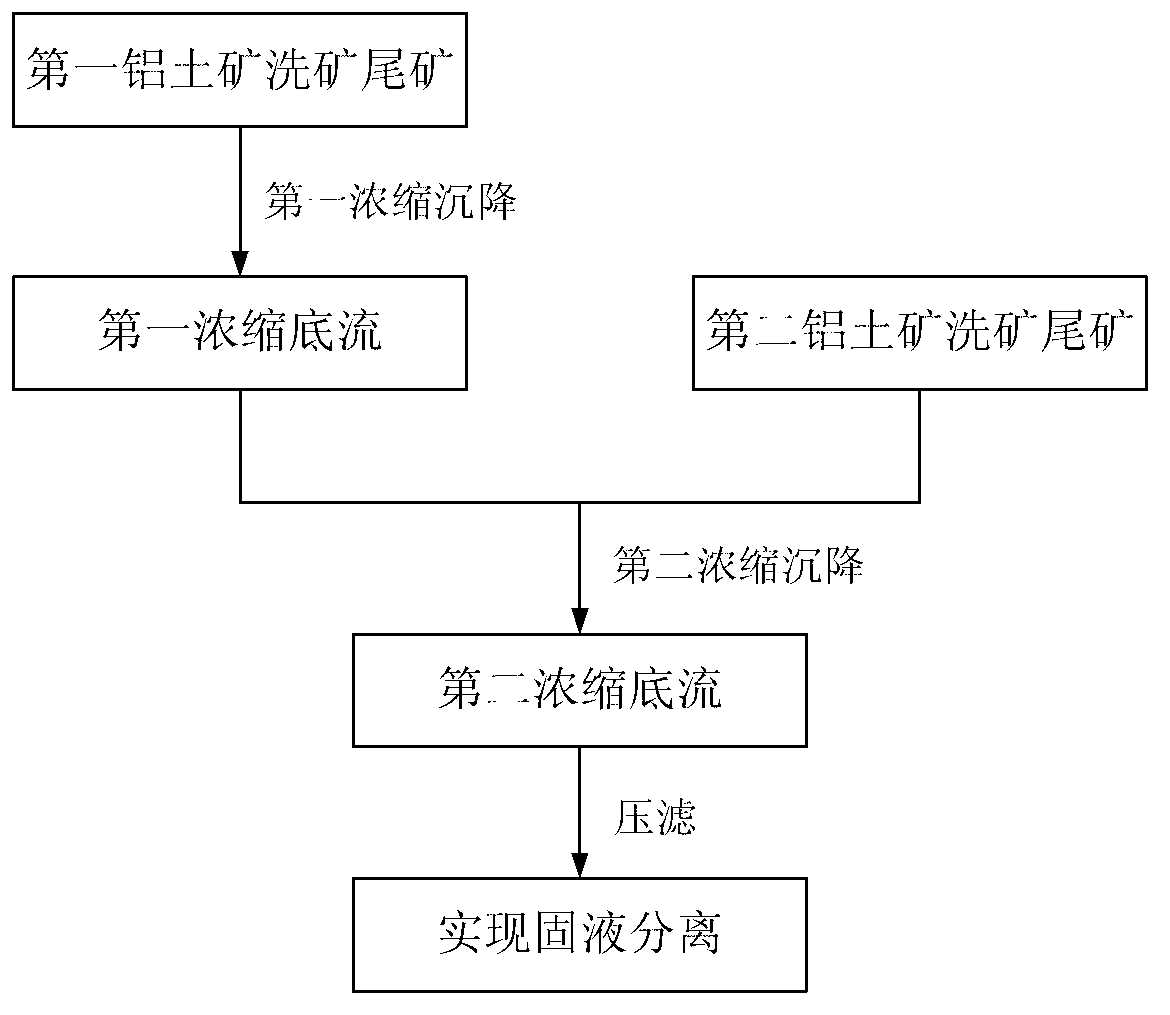

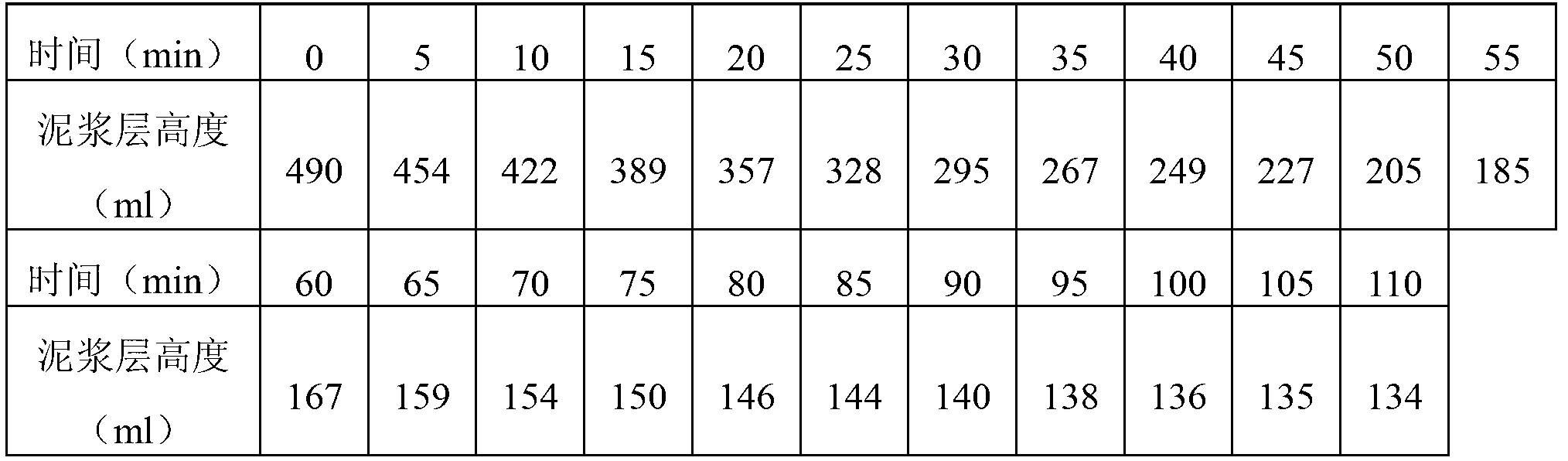

[0031] refer to figure 1 , according to the following method, determine the time of the second concentrated settlement in the method for processing bauxite washing tailings of the present invention:

[0032] Samples and reagents: bauxite washing tailings with a concentration of 7%;

[0033] Flocculant (Yunnan Fenghuo Technology Co., Ltd. FHG-A15 mining polymer flocculant, sometimes referred to as "FGH-A15 flocculant" in this article).

[0034] method:

[0035] First, the above-mentioned bauxite washing tailings are transported to the high-efficiency thickener (Huaibei Mining Machinery) model NZT-50, and FHG-A15 flocculant is added to it, so as to conduct the first Concentrate and settle for 100 minutes to obtain the first concentrated underflow with a concentration of 20%, wherein 200 grams of the flocculant is added to each ton of bauxite washing tailings. After weighing the dry weight, the ratio of the dry weight to the wet weight is the underflow concentration.

[0036]...

Embodiment 2

[0042] refer tofigure 1 According to the method of the present invention, the bauxite washing tailings (concentration is 7%) are processed according to the following steps:

[0043] First, transport the bauxite washing tailings to the NZT-50 high-efficiency thickener, and add FHG-A15 flocculant to it, so that the bauxite washing tailings can be concentrated and settled for 110 minutes to obtain a concentration of 20 % of the first concentrated underflow, wherein 200 grams of the flocculant is added to each ton of bauxite washing tailings.

[0044] Next, the first concentrated underflow is pumped to the ore washing tailings pipeline, where it is mixed with bauxite ore washing tailings in a weight ratio of 10:3, and FHG-A15 flocculant is added to the mixture, and then Transported to the aforementioned high-efficiency concentrator, so as to carry out the second concentrated sedimentation for 110 minutes, to obtain the second concentrated bottom flow with a concentration of 30%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com