Self-propelled pavement floor tile recycling device

A recycling device and sidewalk technology, applied in the field of self-propelled sidewalk floor tile recycling devices, can solve the problems of aging and damage to sidewalk floor tiles, large workload, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

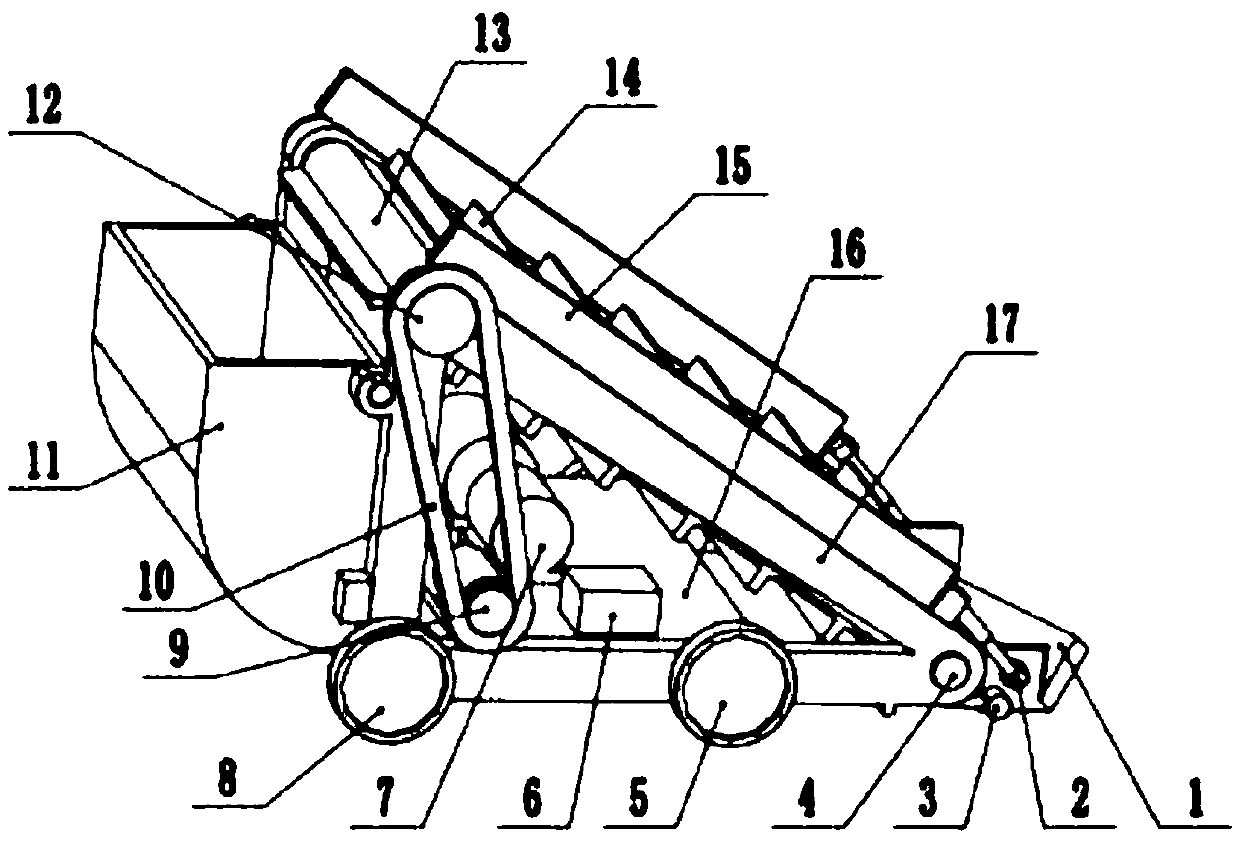

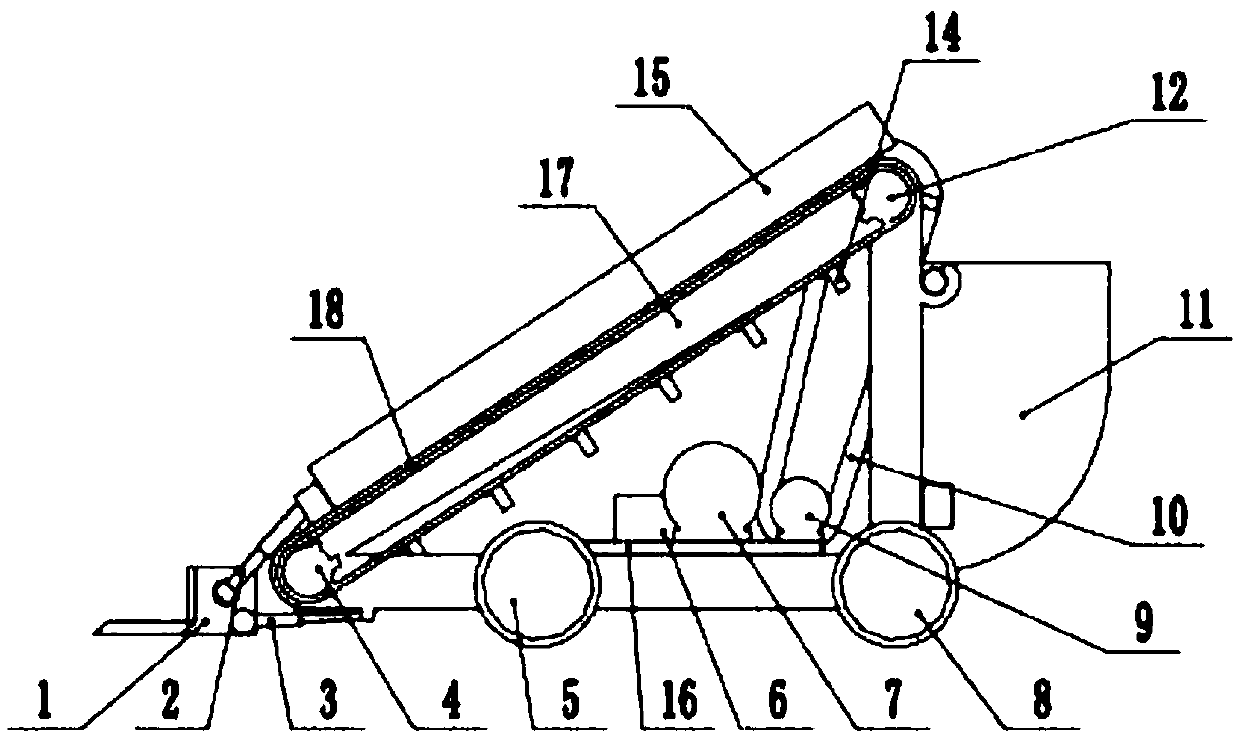

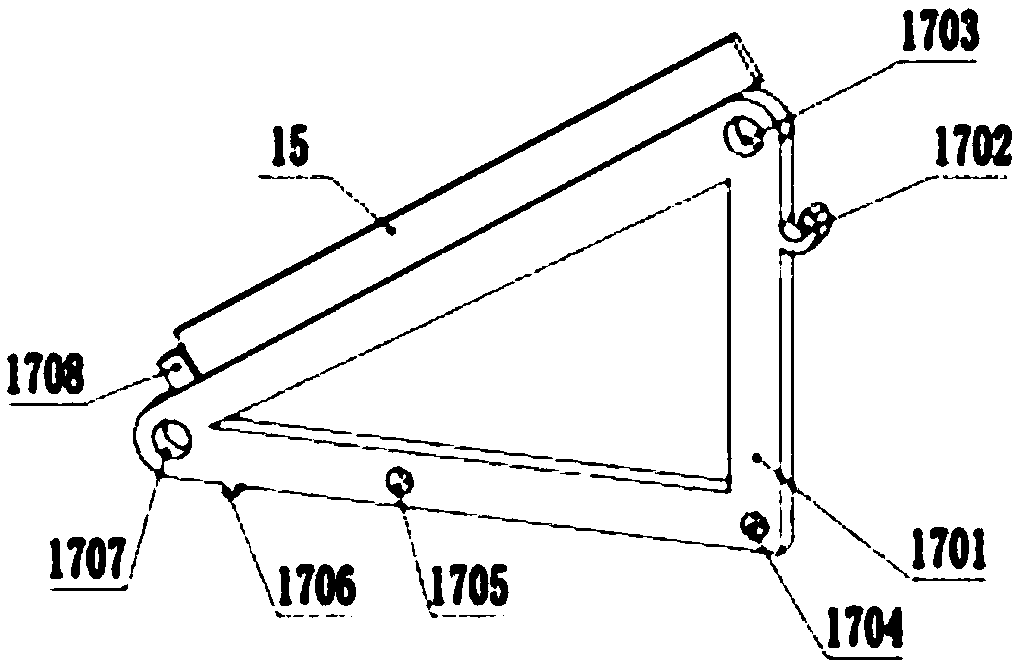

[0014] A self-propelled pavement floor tile recovery device is composed of a front shovel 1, a first hydraulic cylinder 2, a second hydraulic cylinder 3, a lower transmission shaft 4, a front wheel 5, a controller 6, a hydraulic energy supply module 7, and a rear wheel 8 , hydraulic motor 9, first chain 10, storage box 11, upper transmission shaft 12, transmission belt 13, feeding plate 14, baffle plate 15, lower plate 16, frame 17 and second chain 18, the front The shovel 1 is structurally divided into a shovel body 101, a first bump 102 and a second bump 103, and the frame 17 is structurally divided into a frame main body 1701, a hook 1702, an upper transmission shaft mounting hole 1703, and a rear wheel mounting hole 1704, the front wheel mounting hole 1705, the second hydraulic cylinder mounting block 1706, the lower drive shaft mounting hole 1707 and the first hydraulic cylinder mounting block 1708, the two ends of the first hydraulic cylinder 2 are respectively installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com