Automatic arranging device for magnet rings

An automatic material discharge and magnetic ring technology, which is applied in vibrating conveyors, conveyors, transportation and packaging, etc., can solve the problems of low discharge efficiency and irregular discharge, and achieve the effect of improving efficiency and neat magnetic rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

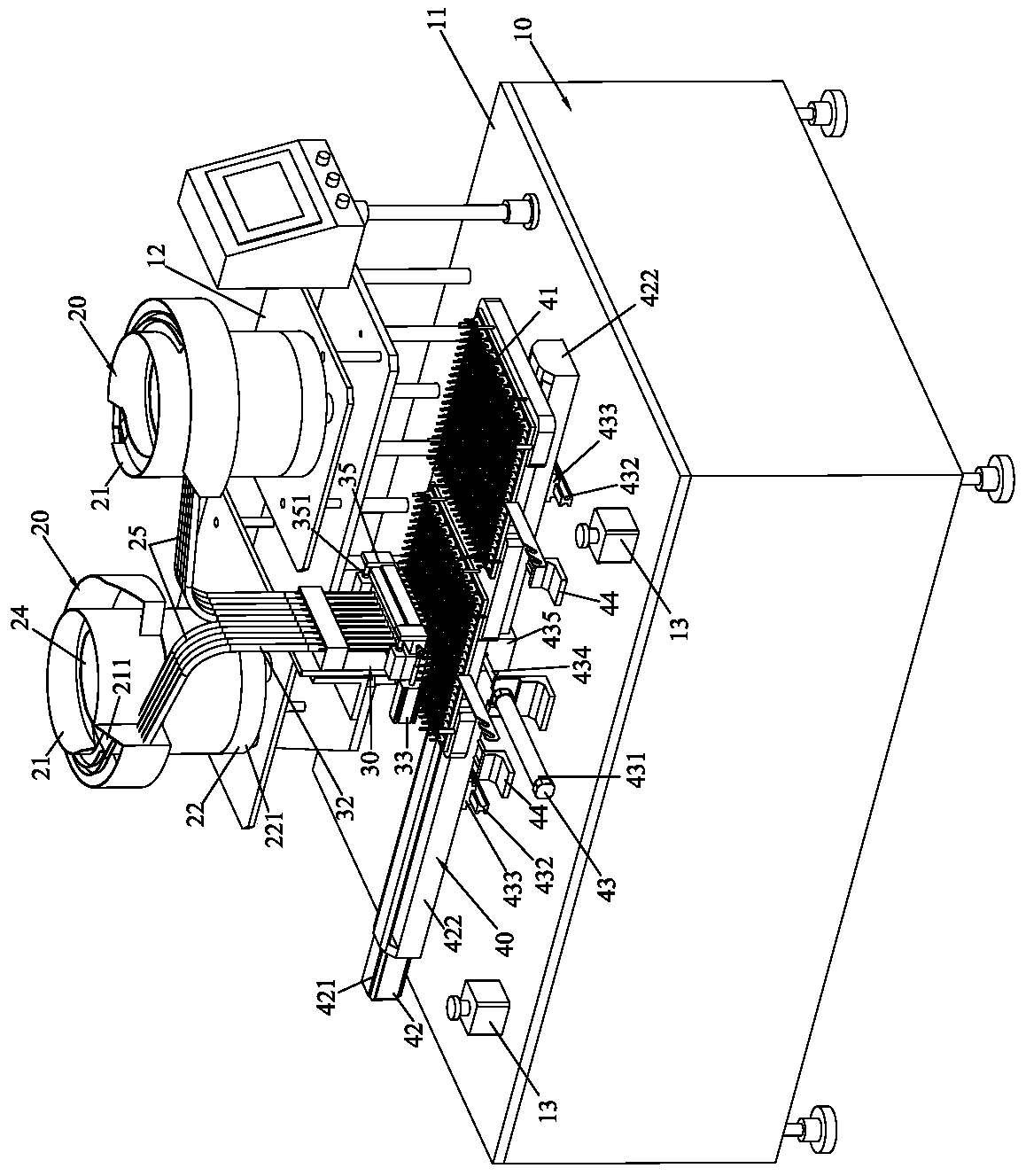

[0052] Please refer to Figure 1 to Figure 7 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a workbench 10, a blanking mechanism 20, an orderly blanking device 30 and a discharge platform 40 for magnetic rings.

[0053] There is a working plane 11 on the workbench 10 , and a bracket 12 and two emergency stop buttons 13 are arranged on the working plane 11 .

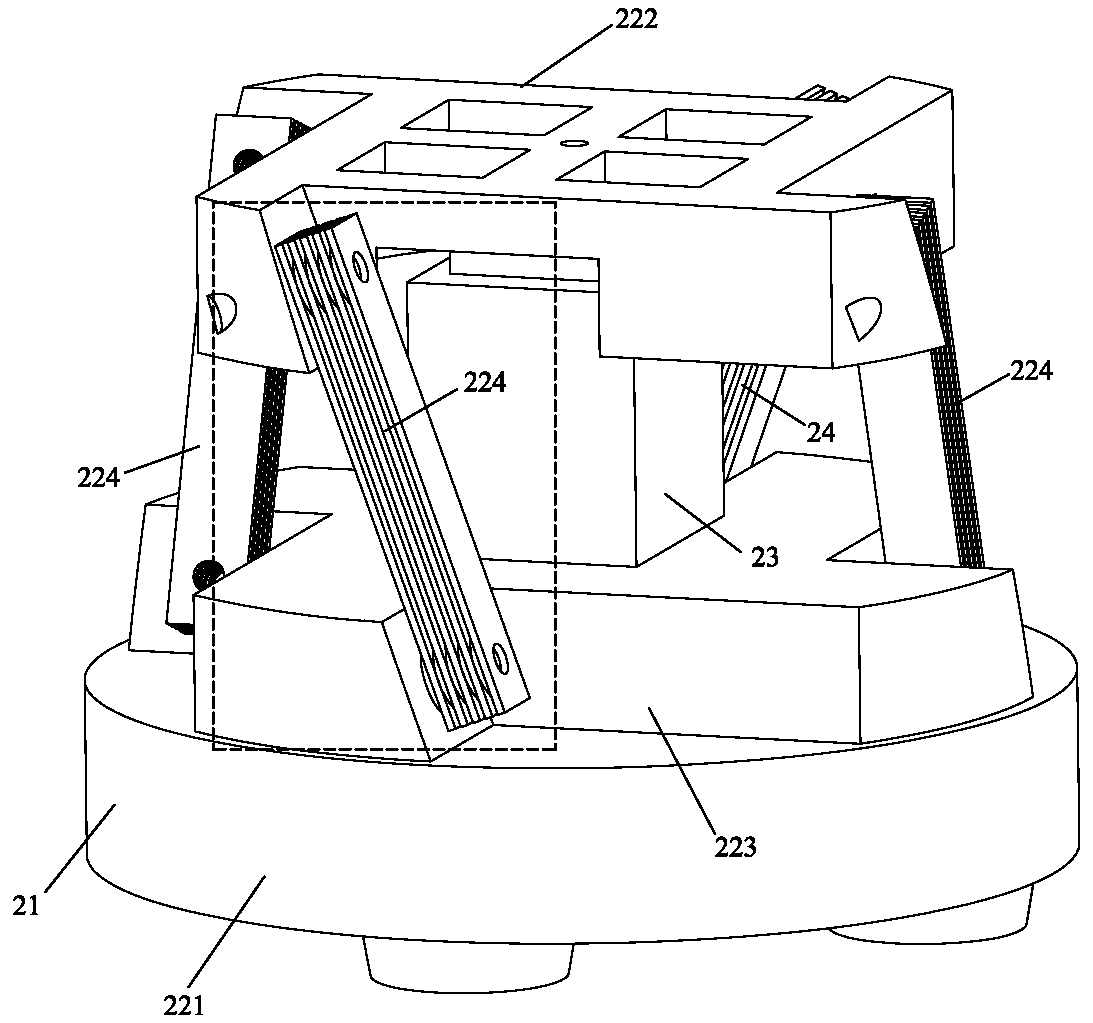

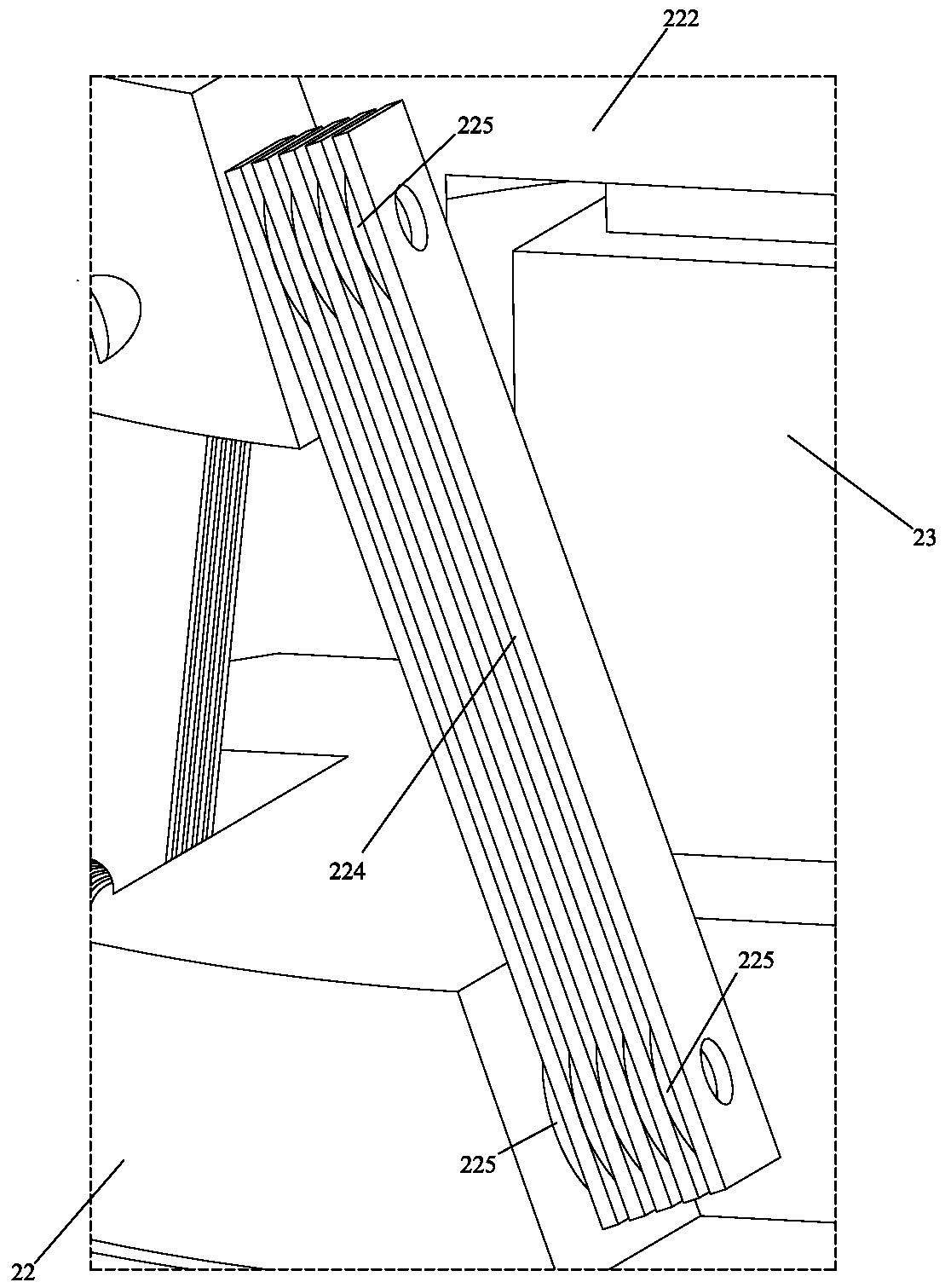

[0054] The unloading mechanism 20 is arranged on the bracket 12. The unloading mechanism 20 includes a chassis 21, a rotating mechanism 22, a vibrating mechanism 23, a spiral ascending passage and a feeding passage. The chassis 21 includes a bottom rotating body and an outer wall. The rotating body can rotate around its own axis. The chassis 21 is concavely provided with an accommodating cavity 24 for placing magnetic rings. The accommodating cavity 24 is used for placing a large number of messy magnetic rings to be processed. A discharge port 211 is provided on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com